Handling and managing device

A technology for equipment and processing devices, applied in lighting and heating equipment, furnace components, instruments, etc., can solve the problem of spending a lot of time and cost, and achieve the effect of reducing time and cost, reducing load and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

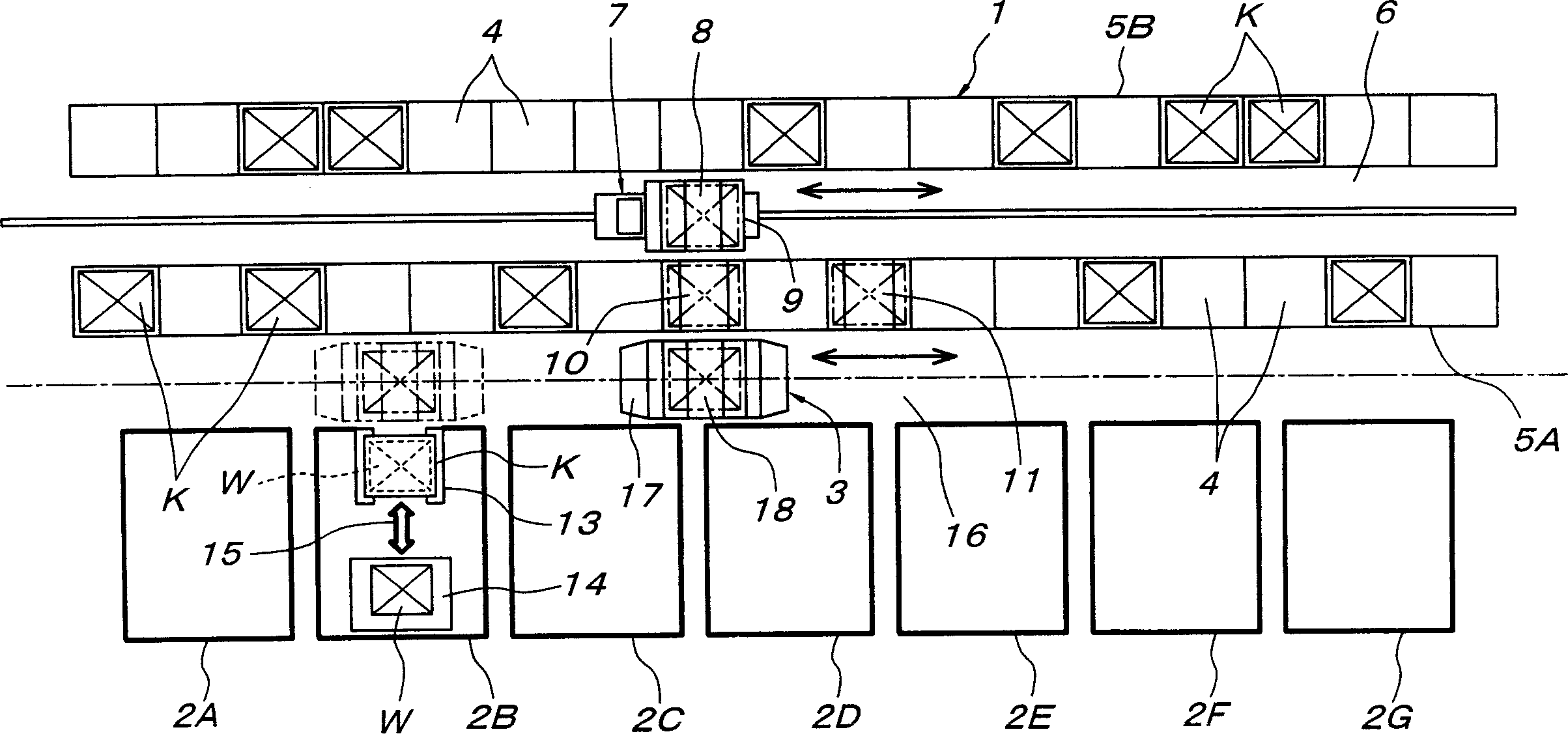

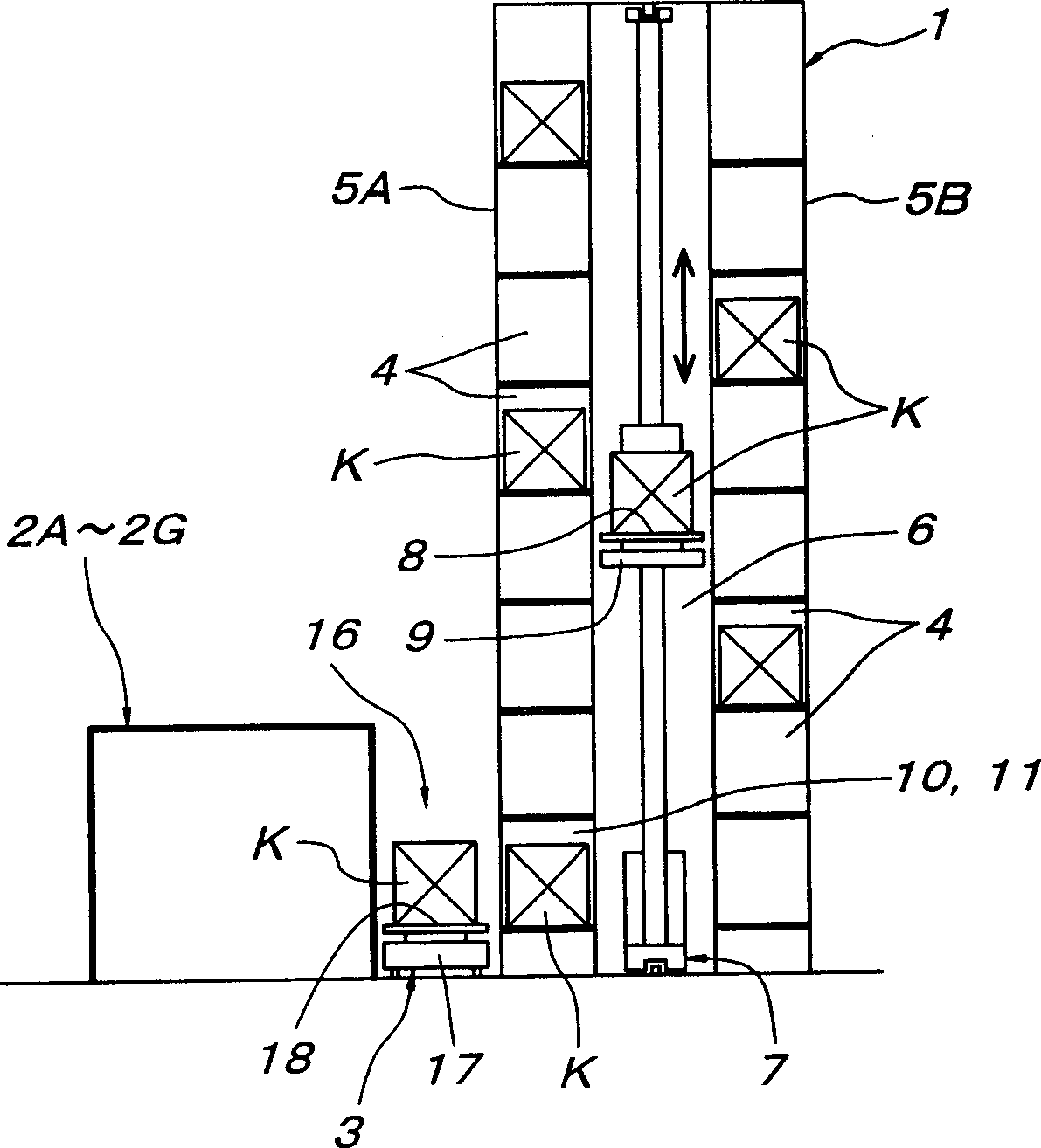

[0010] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings. 1 is an automatic warehouse, 2A to 2G are a plurality of processing devices installed on one side of the automatic warehouse 1, and 3 is a transfer device arranged between the automatic warehouse 1 and the row of processing devices. device. The automatic warehouse 1 is composed of two rows of racks 5A, 5B each having three-dimensional storage compartments 4, and a lifter 7 for loading and unloading disposed in a passage 6 between the racks 5A, 5B. This warehouse-in and out-of-warehouse jack 7 is known, and a transfer mechanism (working fork, etc.) 8 is mounted on its lifting tray 9, and it is used to receive the storage compartment 4 on the two shelves 5A, 5B. Box K as the conveyance. In addition, the delivery port 10 and the storage port 11 between the transport device 3 and the transport device 3 are provided on the shelf 5A adjacent to the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com