Vibrating funnel fingers for distribution of seasoning onto discrete lames

A technology for condiments and fingers, which is applied in the field of vibrating funnel fingers for distributing condiments to separation channels, can solve problems such as changing characteristics, and achieve uniform distribution, continuous distribution, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

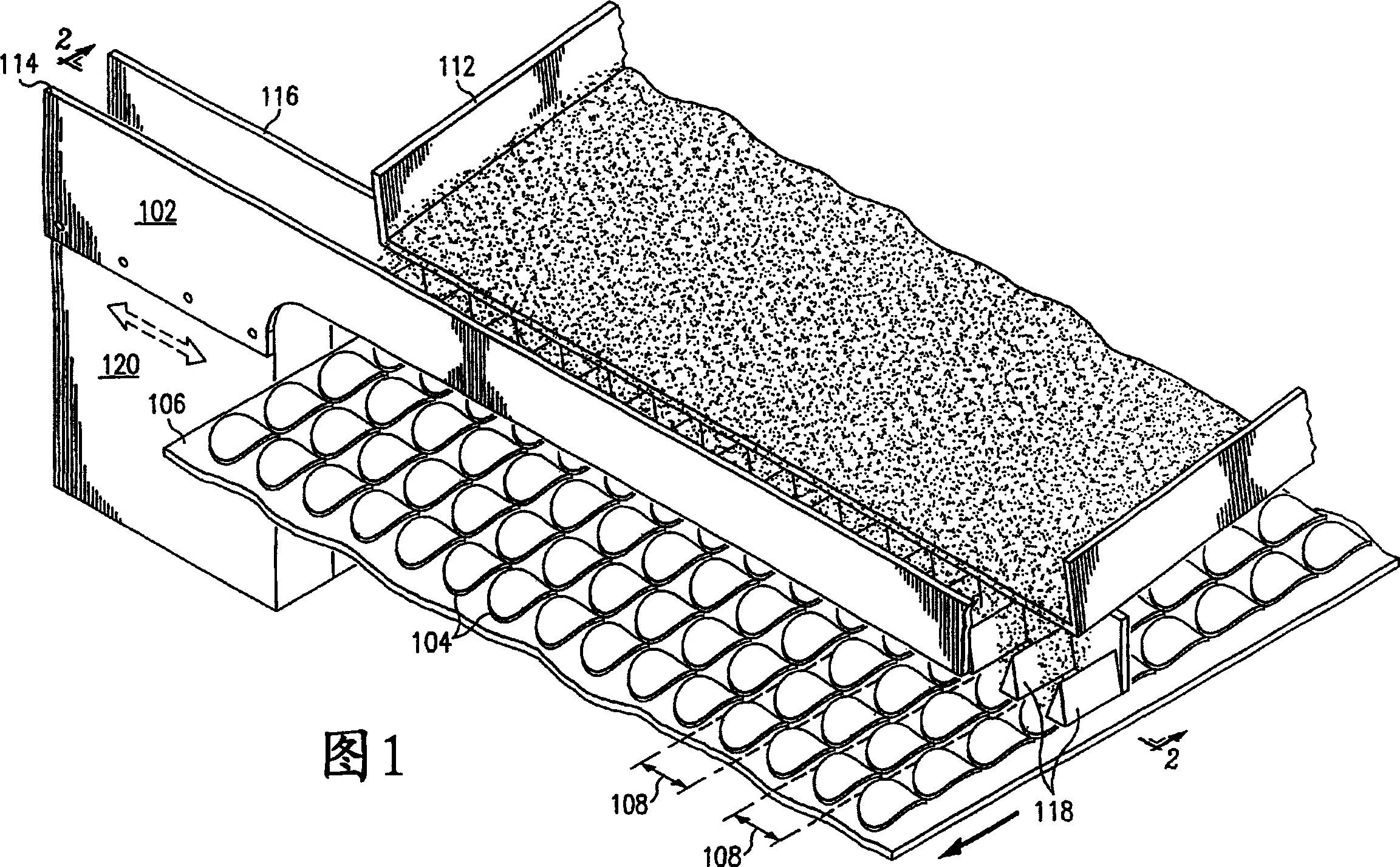

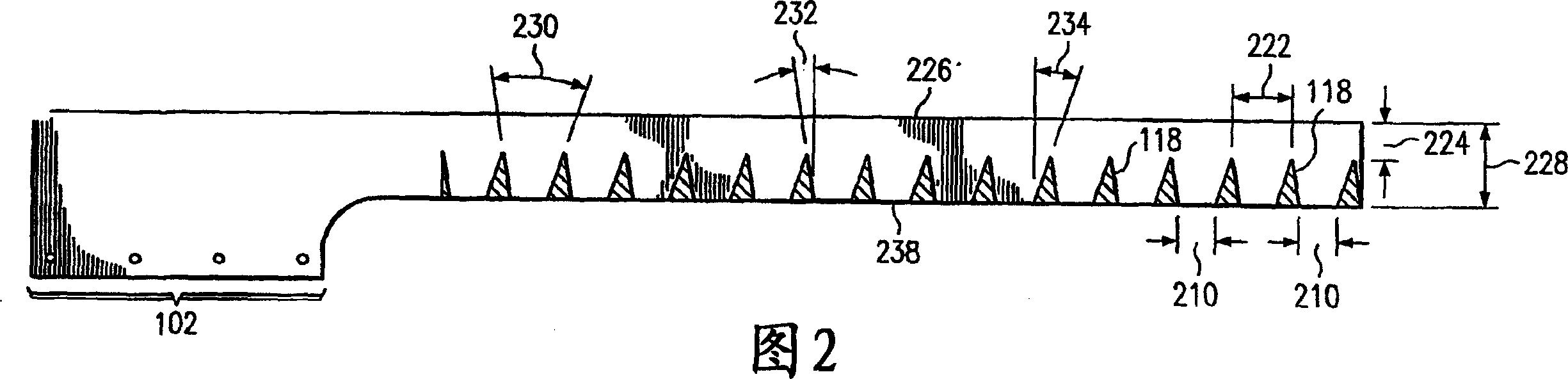

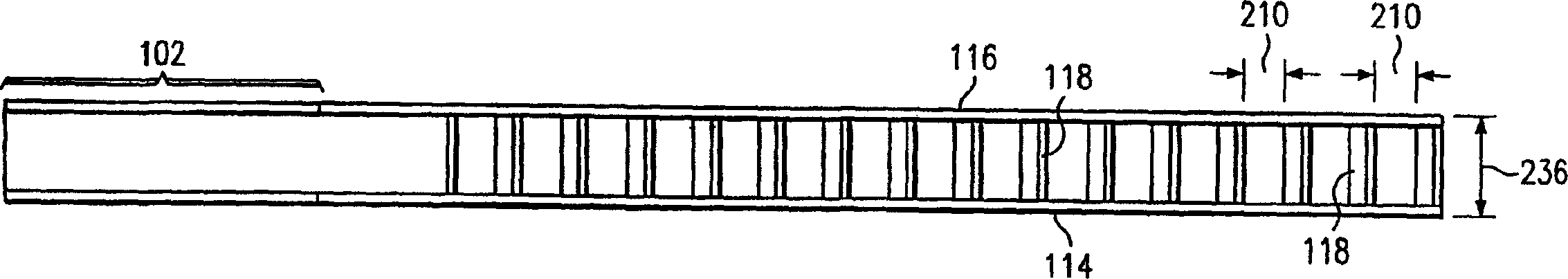

[0016] Figure 1 is a perspective view of a condiment distribution track or trough 102 of the present invention suspended above a condiment conveyor 106. In the illustrated embodiment, the track 102 includes two parallel plates 114, 116 and a plurality of distributors 118 that define the funnel fingers of the present invention.

[0017] The conveyor 106 may be, for example, a porous belt conveyor to allow excess condiments to fall through the conveyor 106 so that it can be collected below, or the conveyor may be a conventional belt conveyor and be Excessive condiments are collected at the end of the hopper 106, as long as the sheet-like items maintain their orientation. As with the existing seasoning technology involving stackable sheet-like articles, each sheet-like article 104 moves downward along the conveyor 106 in the separation channel 108. For each channel 108 of the sheet-like article, there is a corresponding hole at the bottom of the distribution track 102 (as shown by re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com