Steam distribution device for direct air-cooled condenser for power station

An air-cooled condenser and steam distribution technology, which is used in steam/steam condensers, lighting and heating equipment, etc., can solve problems such as the adverse effect of direct air-cooled condenser heat exchange, avoid uneven distribution of steam, reduce Eddy, smooth flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

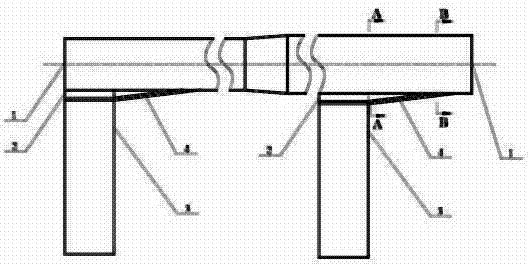

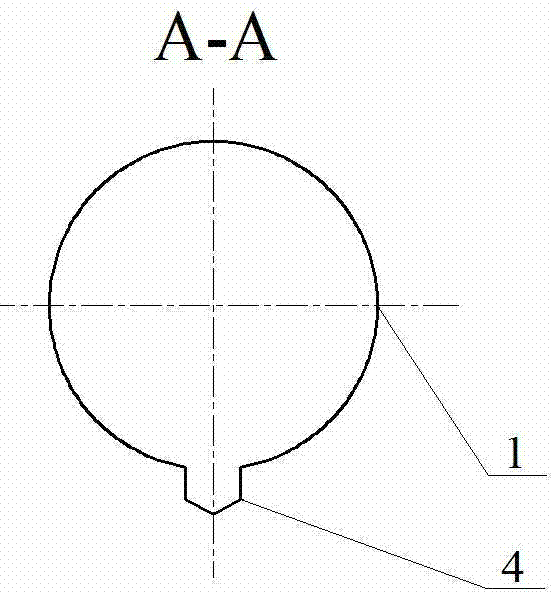

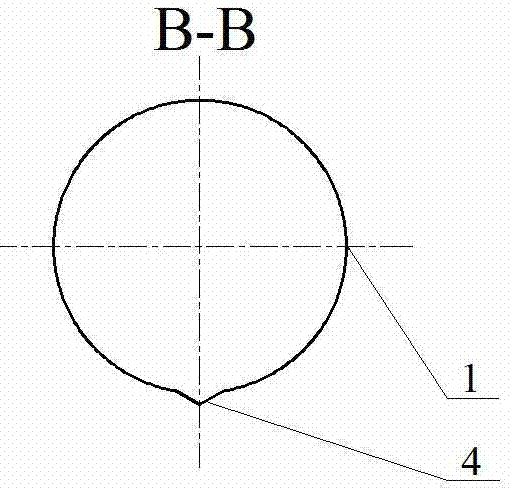

[0014] from figure 1 It can be seen from the figure that a steam distribution device of a direct air-cooled condenser in a power station includes a steam distribution pipe 1, a steam distribution pipe box 2, a finned heat exchange tube bundle 3, and the like. The steam distribution pipe 1 communicates with the finned heat exchange tube bundle 3 through the steam distribution pipe box 2, specifically, the bottom of the steam distribution pipe 1 and the top of the finned heat exchange tube bundle 3 are welded together through the steam distribution pipe box 2, and the steam The distribution tube box 2 plays the role of connecting the steam distribution tubes and the finned heat exchange tube bundles. The steam in the steam distribution pipe 1 enters the finned heat exchange tube bundle 2 through the connection of the steam distribution pipe box 2 for cooling and heat exchange.

[0015] The feature of the present invention is that: the steam distribution pipe 1 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com