Transplanting appts.

A technology of rotating body and terminal gear, which is applied in planting methods, transplanting machinery, applications, etc., can solve the problems of reduced design freedom, increased weight, and increased number of parts, so as to reduce rotational load, improve transmission accuracy, and improve rice transplanting. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] Embodiments of the present invention will be described below with reference to the drawings.

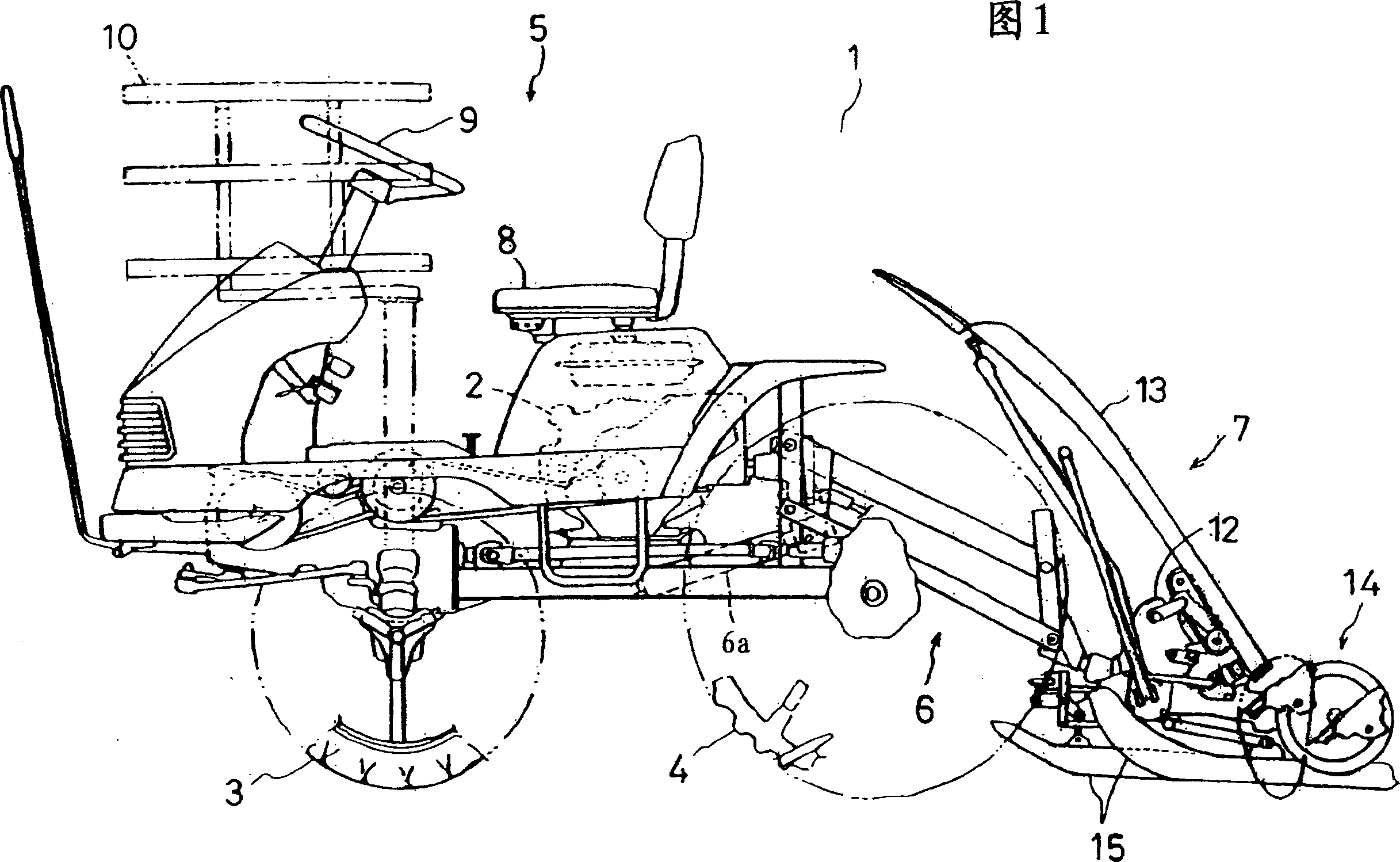

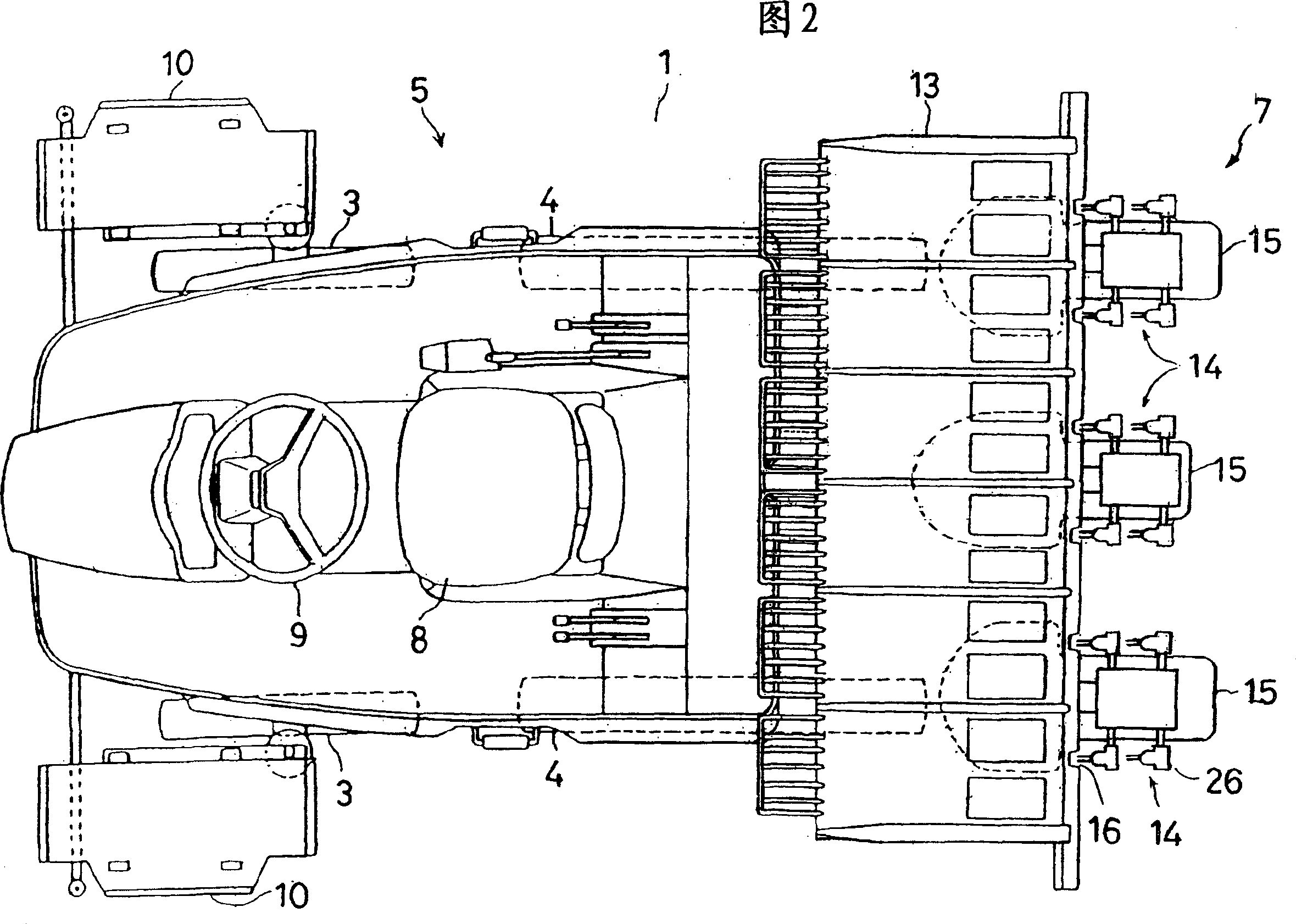

[0086] Fig. 1 and Fig. 2 show a riding rice transplanter equipped with a rice transplanting device according to the present invention. This passenger rice transplanter 1 is equipped with an engine 2, behind a driving vehicle 5 having a pair of left and right front wheels 3, 3 and rear wheels 4, 4 that drive and rotate, and through a lifting rod device 6, six planting paths are connected. The rice transplanting department 7. Symbol 8 among the figure is operating seat, and 9 is the steering wheel of operation front-wheel 3,3, and 10 is the preparatory seedling carrying platform of loading preparatory rice shoot.

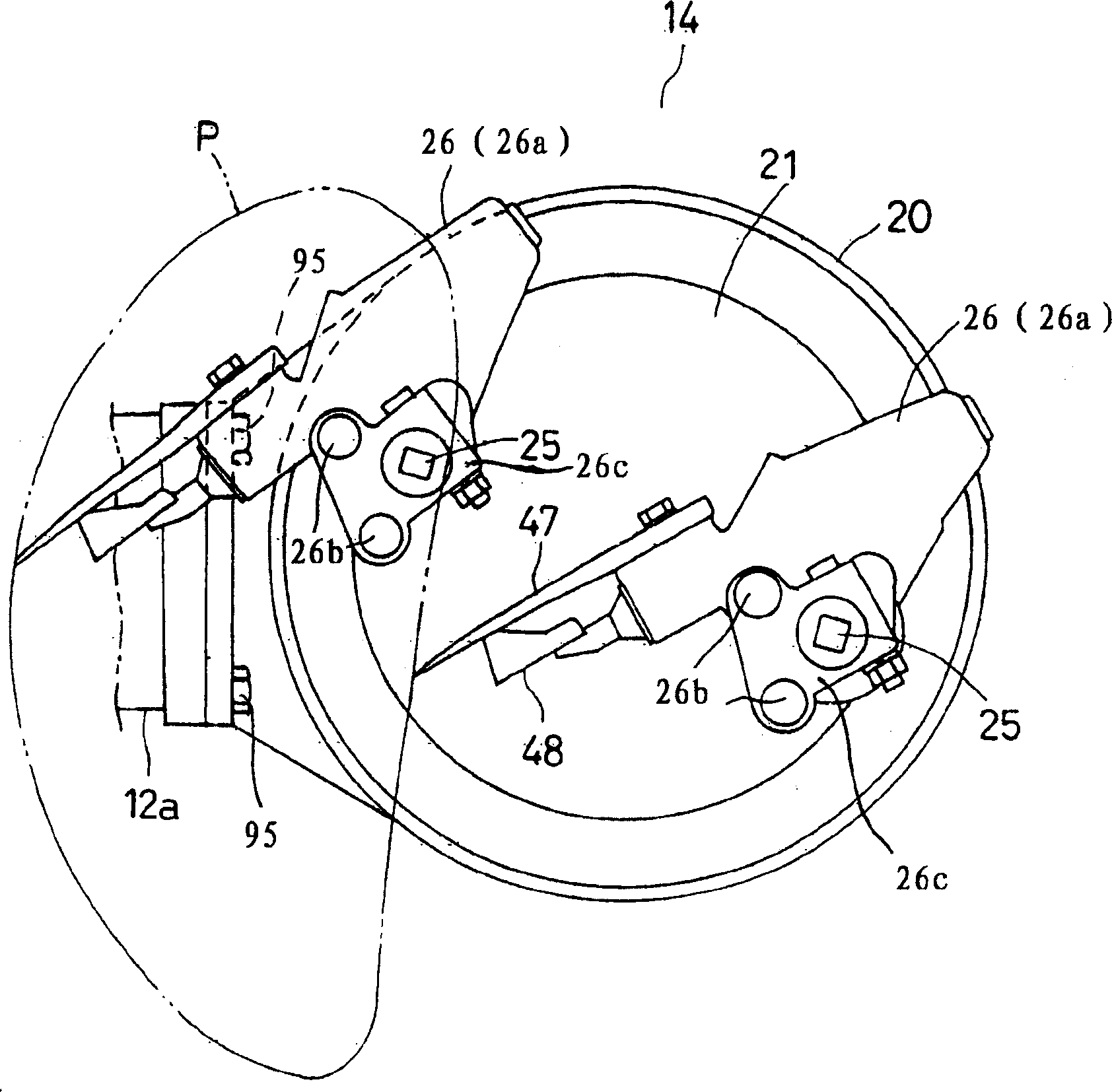

[0087] Transplanting portion 7 is provided with seedling carrying platform 13, and the front portion of this seedling carrying platform 13 is taken as the main position, starts to incline to the upper side of the transmission case 12 of input transmission from travel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com