Semiconductor device, electronic appts. their mfg. methods and electronic instrument

A manufacturing method and semiconductor technology, which are applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, and semiconductor/solid-state device components, etc., can solve the problem of low space saving effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

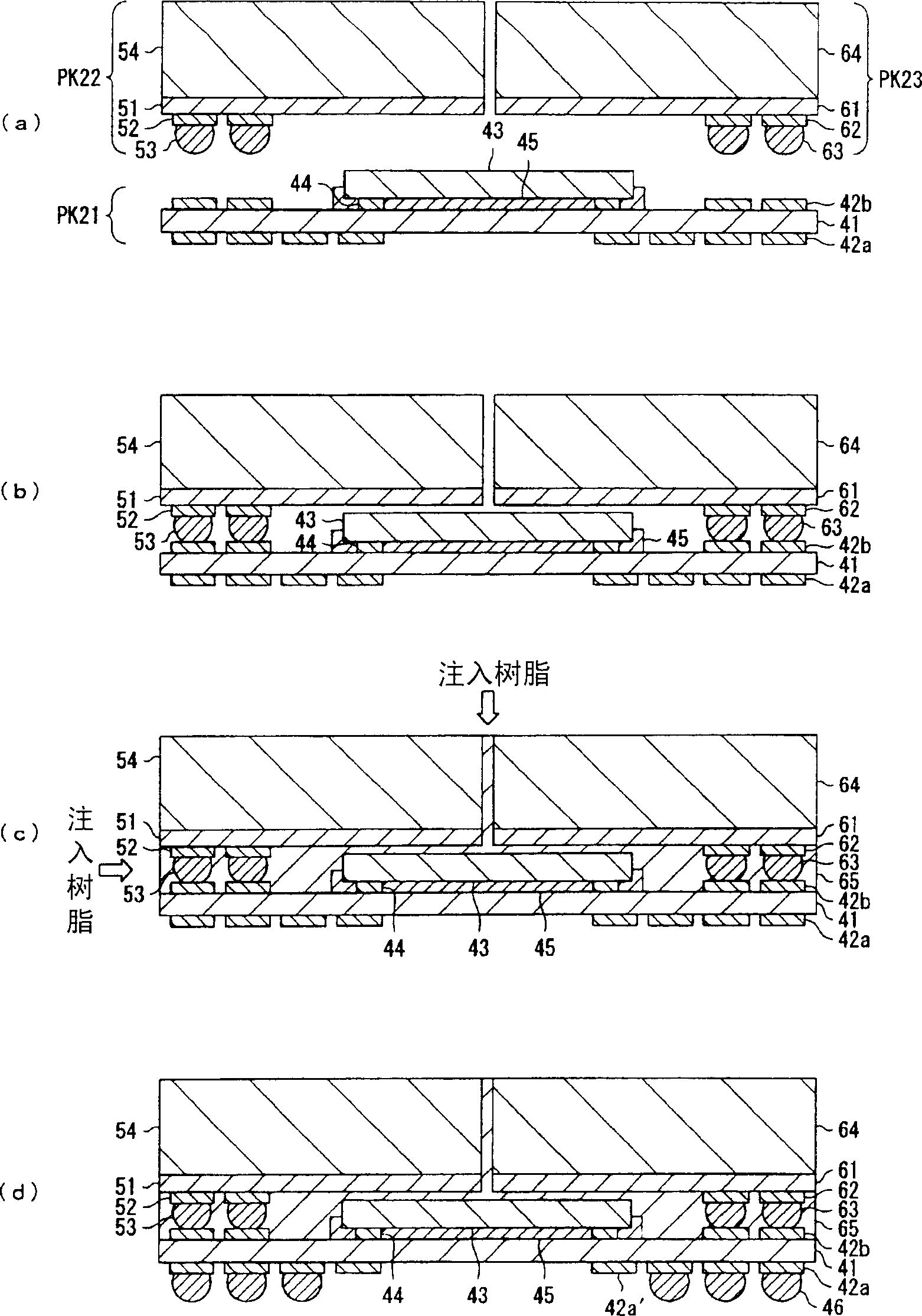

[0051] A semiconductor device, an electronic device, and a manufacturing method thereof according to an embodiment of the present invention will be described below with reference to the drawings.

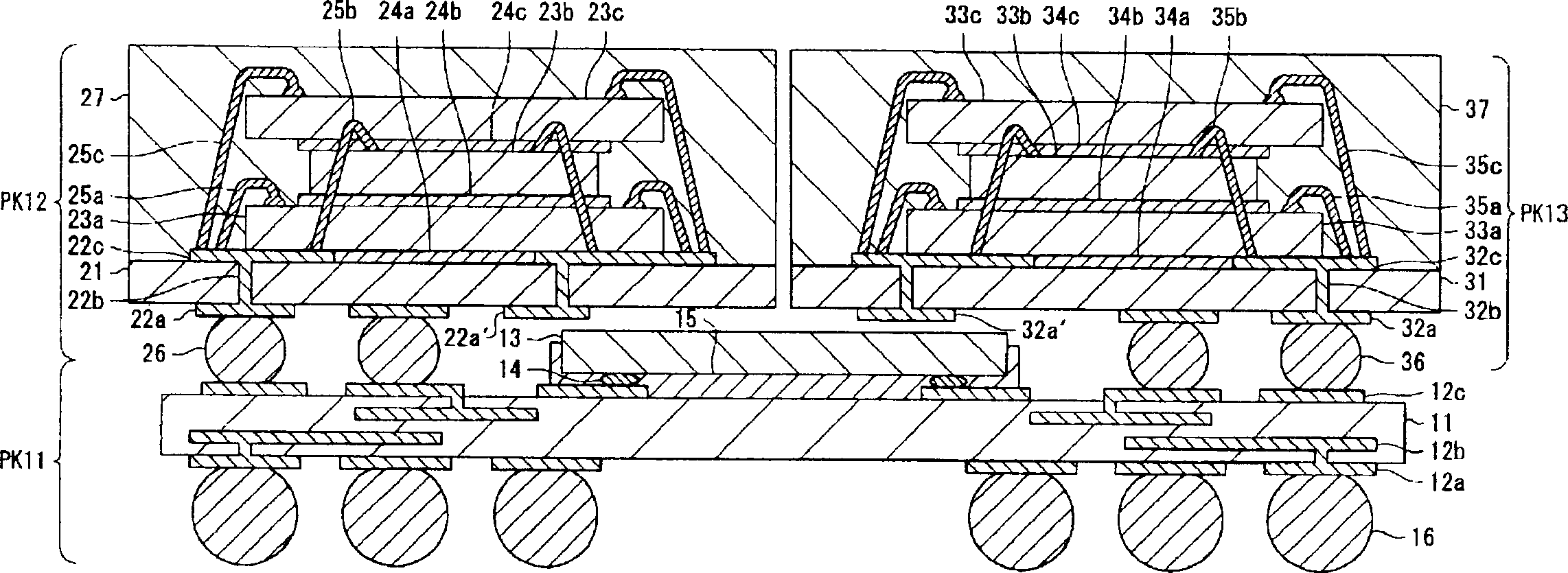

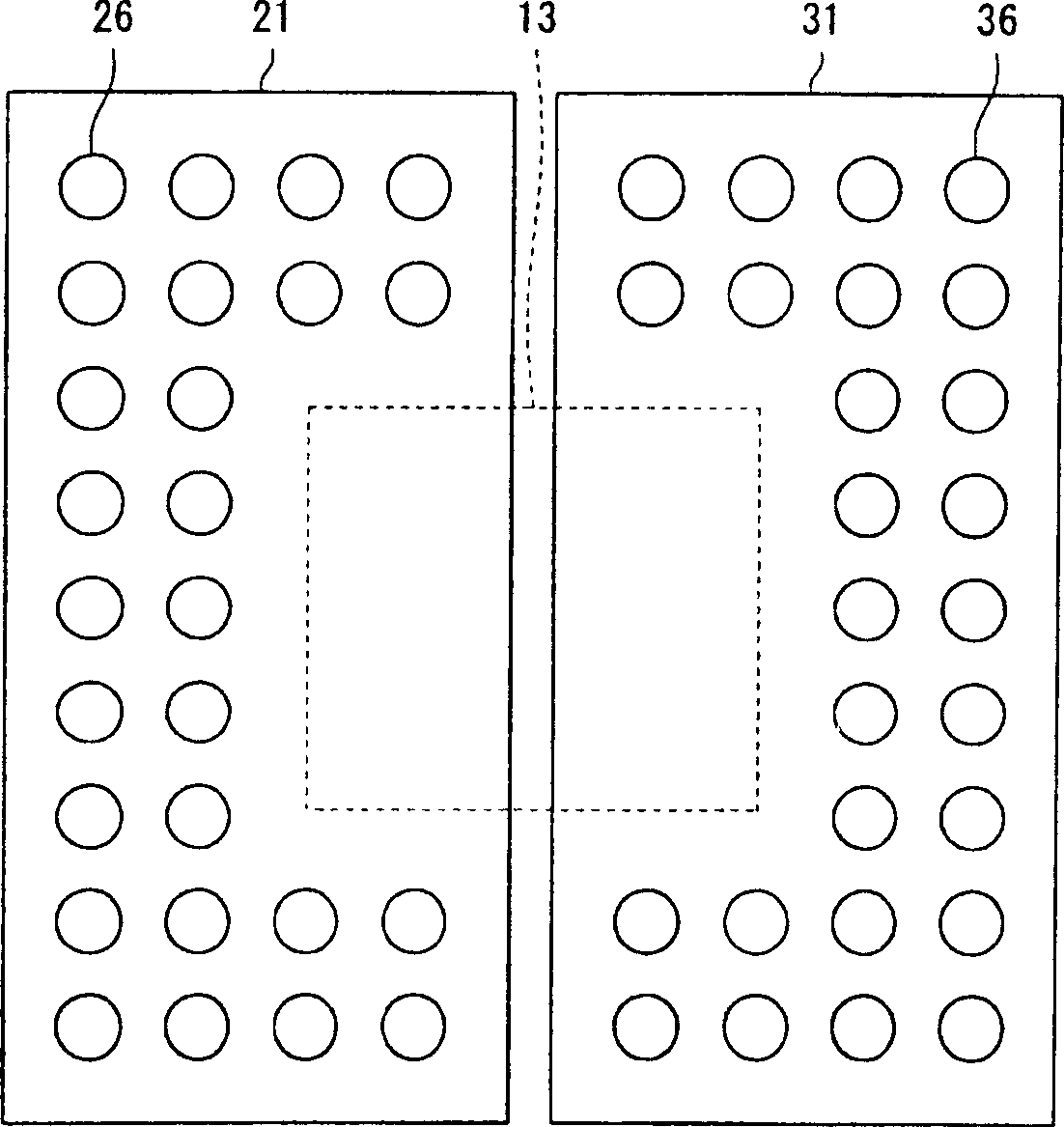

[0052] figure 1 is a cross-sectional view showing the structure of the semiconductor device of the first embodiment of the present invention, figure 2 It is a plan view showing a schematic structure of the semiconductor device of the first embodiment of the present invention. Also, in the first embodiment, on the semiconductor package PK11 in which the semiconductor chips (or semiconductor dies) are mounted by ACF bonding, the semiconductor packages PK12 in which the semiconductor chips (or semiconductor dies) 23a to 23c of the stacked structure are connected by wire bonding are laminated respectively. The semiconductor package PK13 of the stacked semiconductor chips (or semiconductor dies) 33a to 33c is connected by wire bonding.

[0053] figure 1 Among them, a carrier substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com