Method for preparing oxygen for first aid and health care and the oxygen generator

An oxygen generator and oxygen technology, applied in the direction of oxygen preparation, life-saving equipment, respirators, etc., can solve the problems of difficult control of oxygen generation speed, high cost of oxygen generator, inconvenient to carry out, etc., and achieve easy to use, light weight, The effect of low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] This embodiment is based on the organic compound percarbamide [CO(NH 2 ) 2 h 2 O] is the raw material for oxygen production.

[0021] Put percarbamide into water, and collect the decomposed gas, which is the oxygen produced.

[0022] Usually, the water consumption of 25 grams of percarbamide raw materials can be about 60ml, and the oxygen production speed will be accelerated as the temperature rises. The reaction water does not need to be replaced every time, but under normal circumstances, the water should be replaced after about three uses to ensure the oxygen generation rate and the stability of the oxygen generation amount.

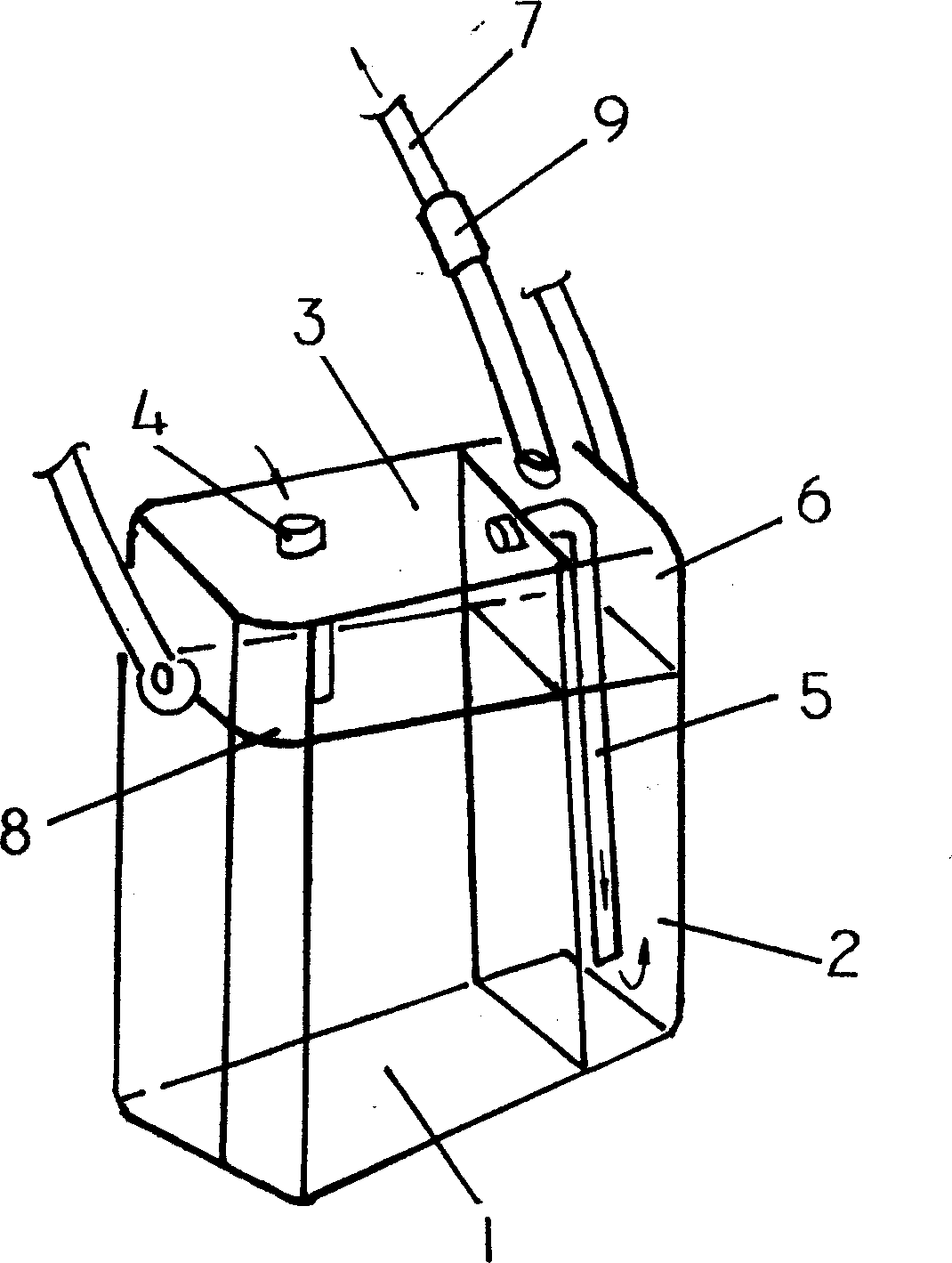

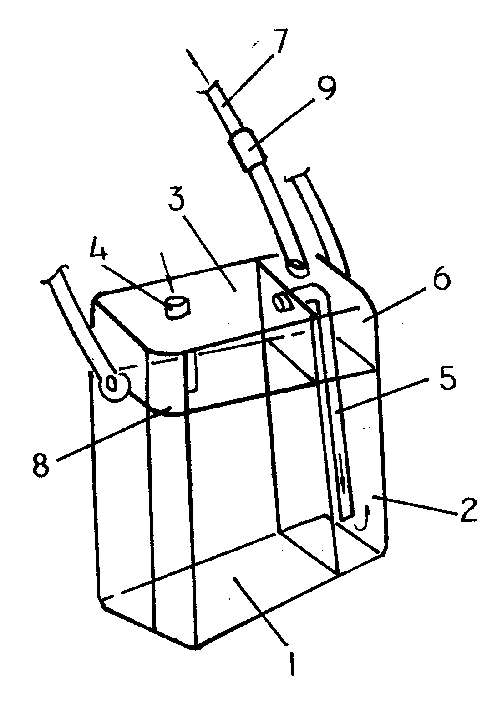

[0023] Referring to Figure 1, the oxygen generator adopts a portable casing, and its inner tank is divided into multiple cavities on the upper, lower, left and right sides, including the oxygen generator chamber 1 which is arranged under the left and right sides and contains water inside. And the purification chamber 2, the top of the oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com