Sodium-based oxygen production molecular sieve and production process thereof

A production process and technology of molecular sieves, applied in the field of molecular sieves, can solve the problems affecting the purity of oxygen, the surface of molecular sieves is not smooth enough, the molecular sieves are deactivated, etc., and achieve the effect of good polishing effect, convenient polishing treatment and better performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

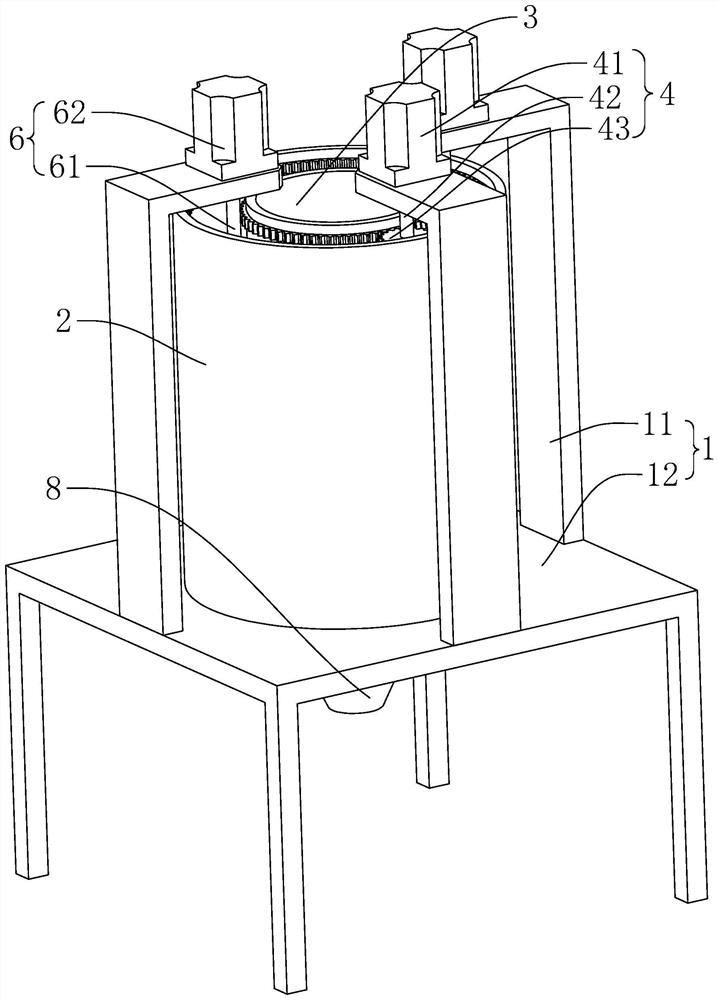

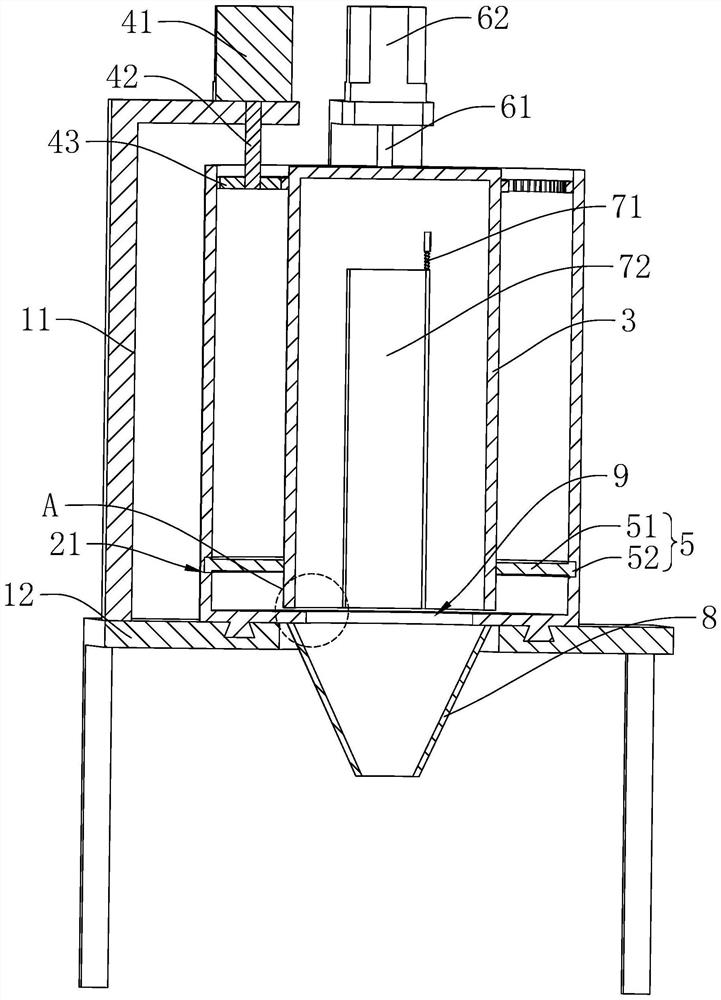

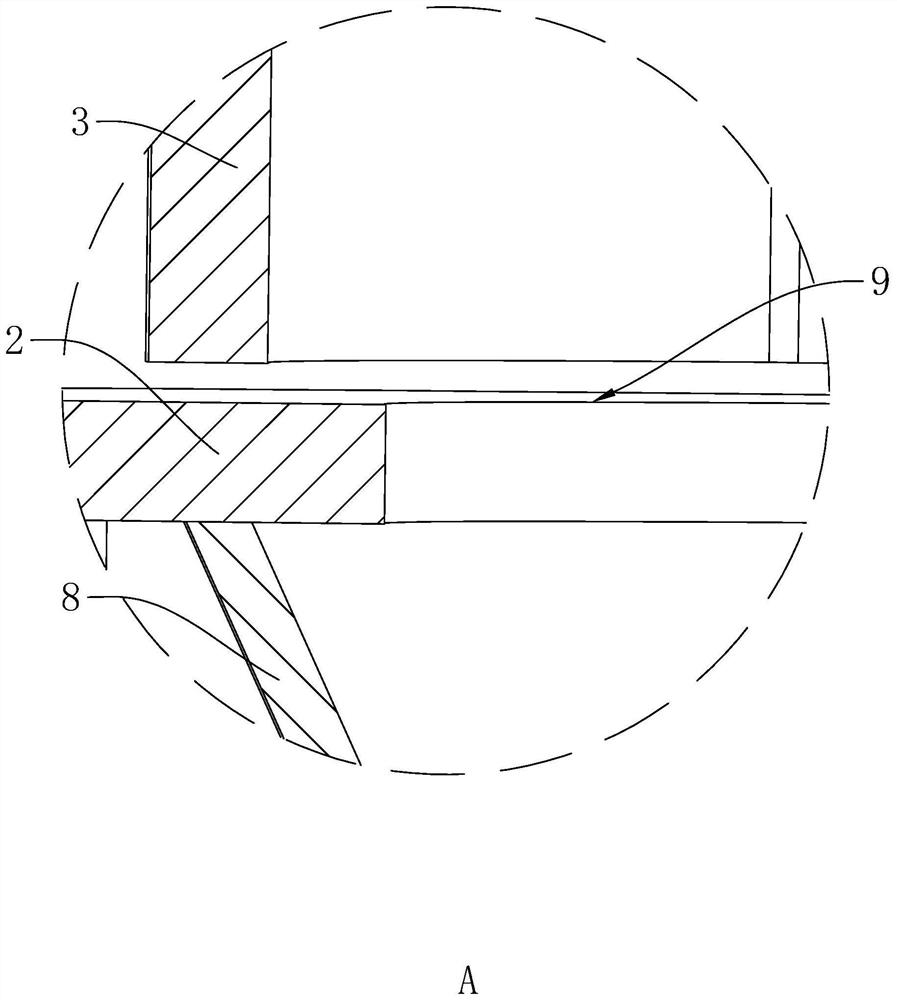

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of this molecular sieve comprises the following steps:

[0043] Dry mixing: first mix and stir the molecular sieve powder and clay, then add solid amine and silane coupling agent to continue mixing and stirring to obtain a mixture;

[0044] Granulation: granulate the mixed material to obtain spherical particles;

[0045] Polishing: polishing the spherical particles to obtain crude products;

[0046] Dehumidification and activation: Dehumidification and activation are performed on the crude product in sequence to obtain a finished molecular sieve.

[0047] The mass parts of each component of the molecular sieve in this embodiment is more preferably 90-110 parts of molecular sieve powder, 40-50 parts of clay, 7-9 parts of solid amine, and 9-11 parts of silane coupling agent.

[0048] The molecular sieve powder in this embodiment is the hydrate of crystalline sodium aluminosilicate;

[0049] The clay in this embodiment includes at least one of kao...

Embodiment 1

[0059] A sodium-based oxygen-producing molecular sieve, comprising the following components in parts by mass: 100 kg of molecular sieve raw powder, 45 kg of clay, 8 kg of solid amine, and 10 kg of silane coupling agent.

[0060] Wherein the molecular sieve raw powder is the hydrate of crystalline sodium aluminosilicate;

[0061] The clay is bentonite;

[0062] The solid amine is a mixture of tetraethylenepentamine, pentaethylenehexamine and polyethyleneimine in a mass ratio of 1:1:4;

[0063] The silane coupling agent is KH-560;

[0064] The ratio of the average particle size of the molecular sieve raw powder to the average particle size of the clay is 9:1.

[0065] The preparation method of this molecular sieve comprises the following steps:

[0066] S1 dry mixing: first mix and stir the molecular sieve powder and clay, control the stirring speed to 1000rpm, adjust the stirring speed to 600rpm after stirring for 1h, add solid amine and silane coupling agent, and continue s...

Embodiment 6

[0082] The difference between this example and Example 1 is that the ratio of the molecular sieve raw powder to the average particle size of the clay is 7:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com