Organic electroluminescence display component and making method thereof

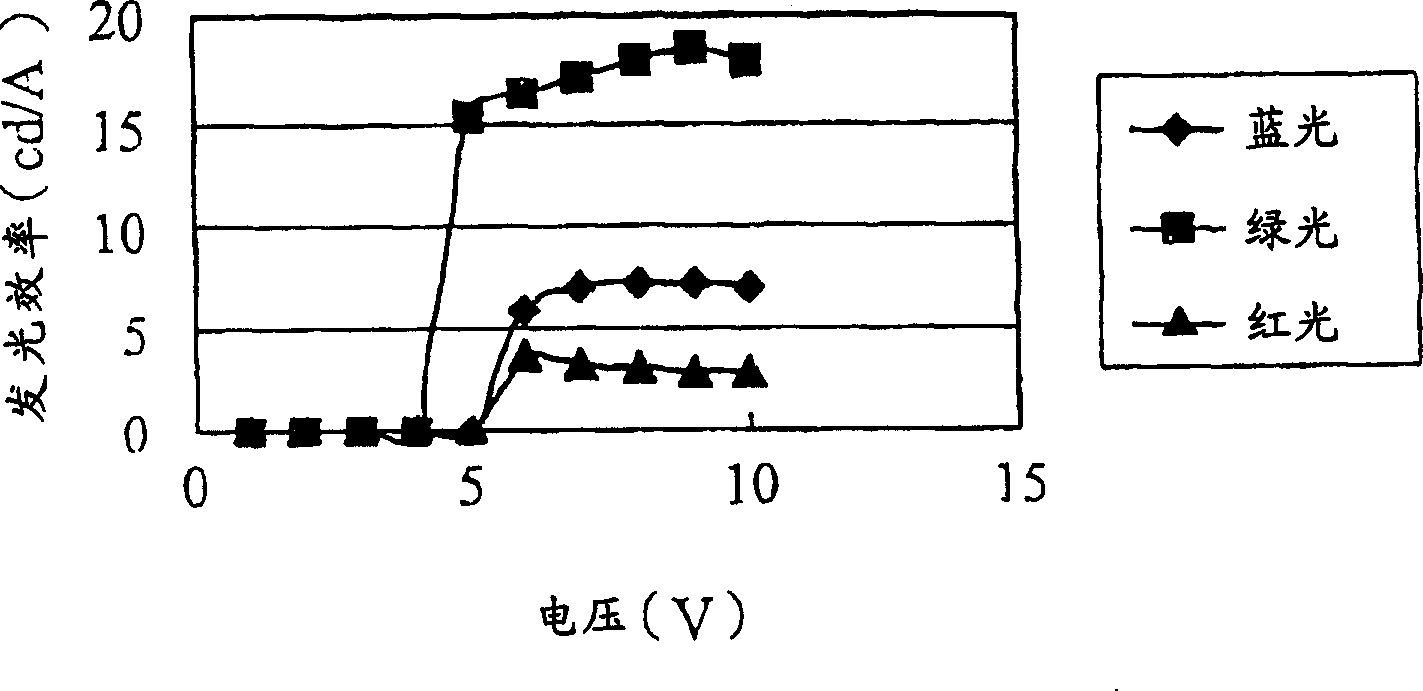

A technology of electroluminescent display and display components, applied in electroluminescent light sources, electric light sources, electrical components, etc., which can solve problems such as low luminous efficiency, difficulty in adding color screens, and low red light intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above-mentioned and other purposes, features, and advantages of the present invention more clearly understood, the preferred embodiments are specifically listed below, together with the accompanying drawings, and are described in detail as follows:

[0021] The present invention proposes an organic electroluminescent display component with high light transmission properties and a manufacturing method thereof, which can be applied to the manufacture of OLED components or PLED components.

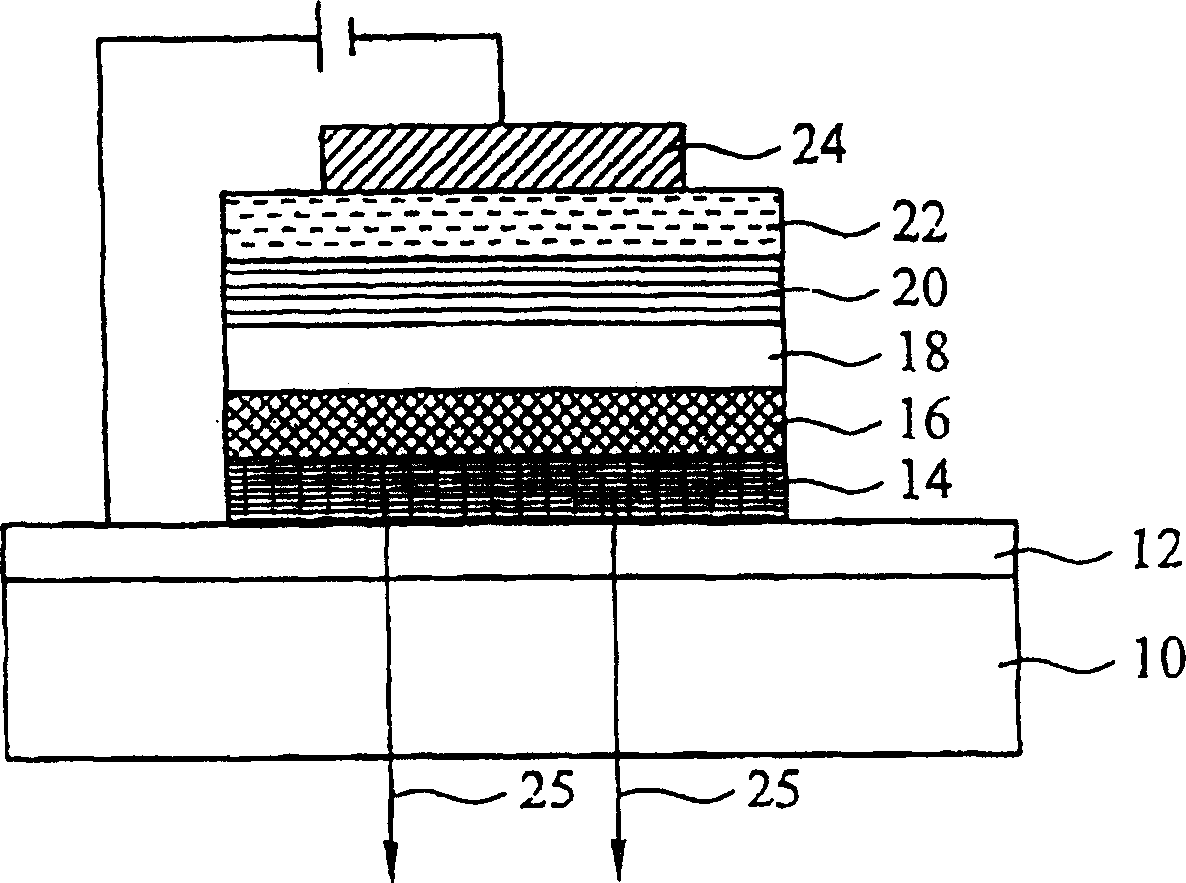

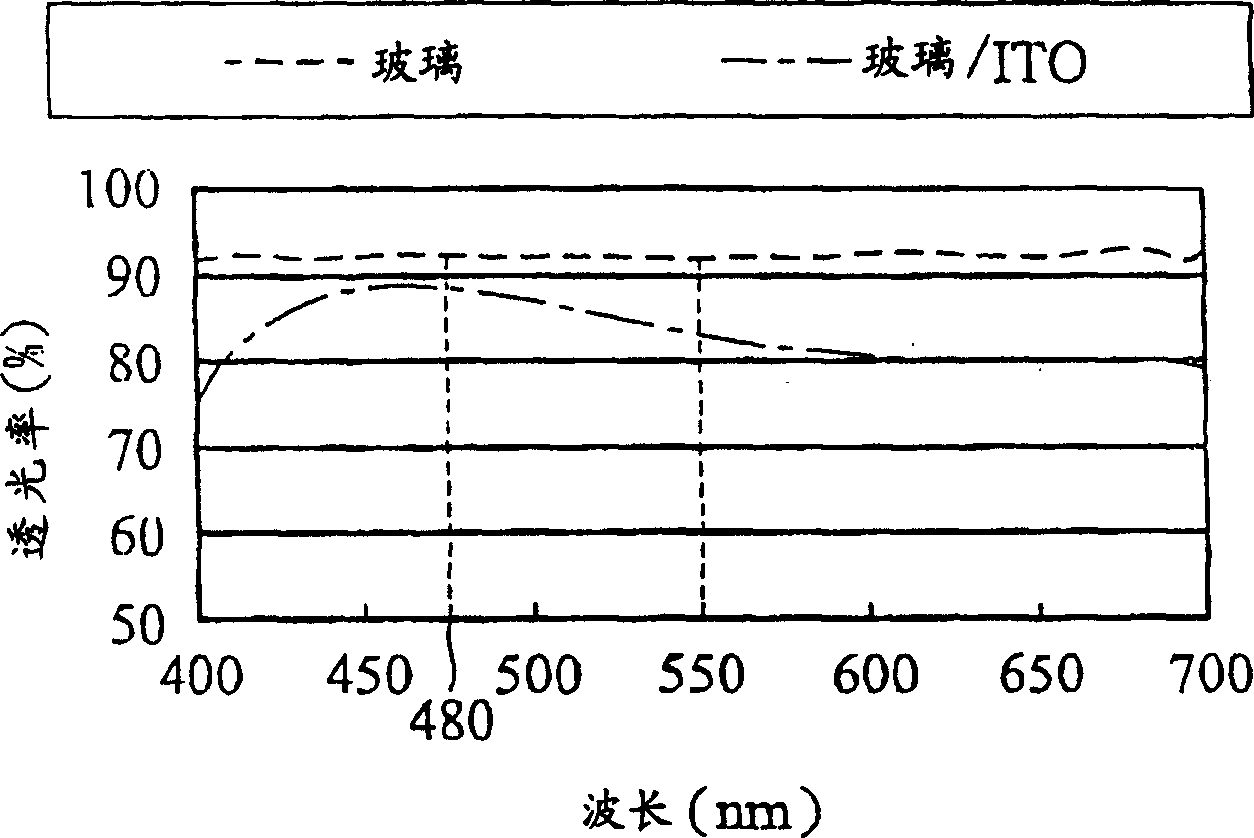

[0022] see Figure 4 , which shows a schematic cross-sectional view of the organic electroluminescent display component of the present invention. A glass substrate 30 includes an optical compensation film 46 , an anode conductive layer 32 , a laminated structure 33 and a cathode conductive layer 44 on the surface. When applied to OLED components, the laminated structure 33 is composed of small molecular organic materials, and when applied to PLED components, the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com