Structure for installing a rear cushion

A rear buffer and buffer technology, applied in the field of hydraulic shock absorbers, to achieve the effect of reducing weight, reducing cost and high installation rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

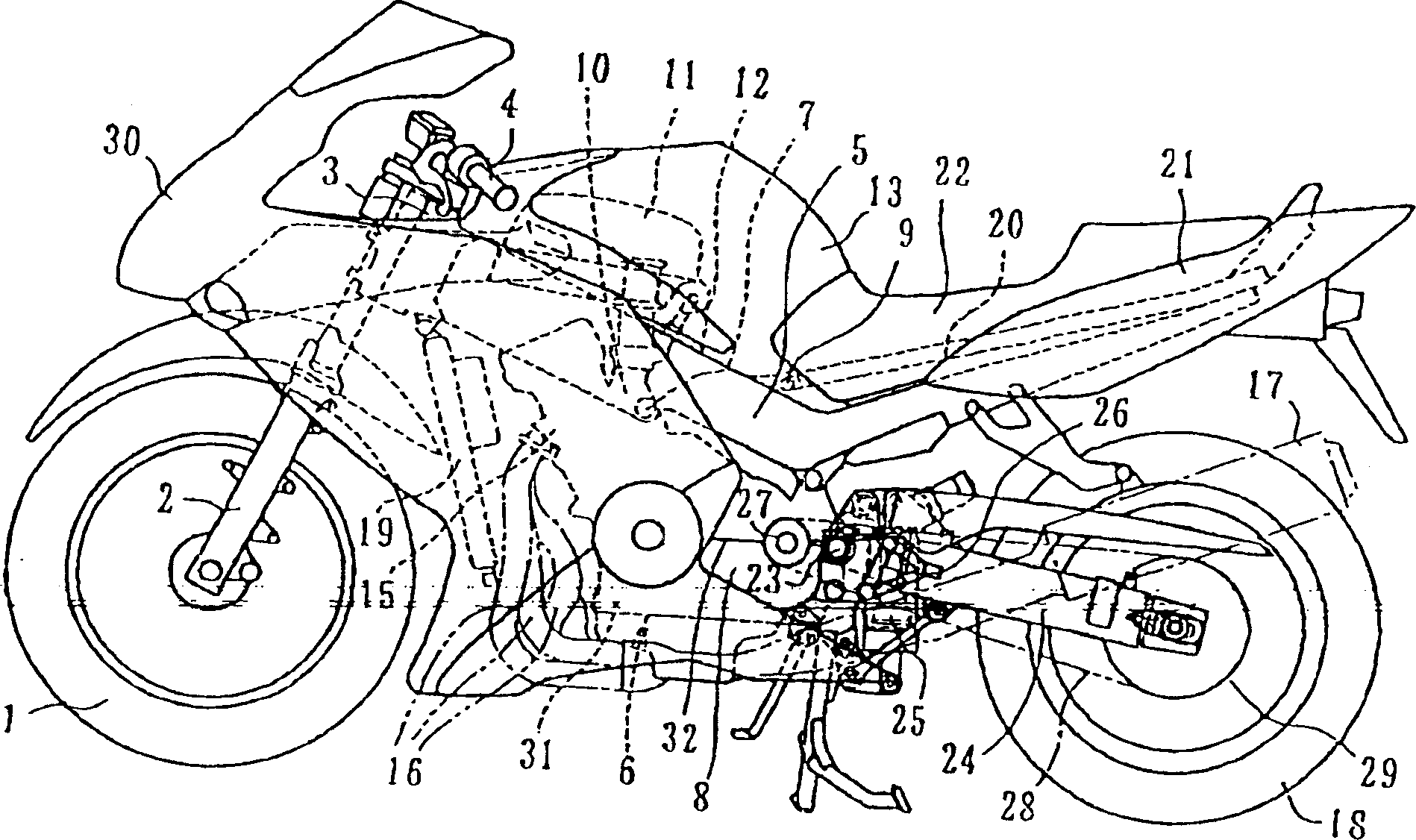

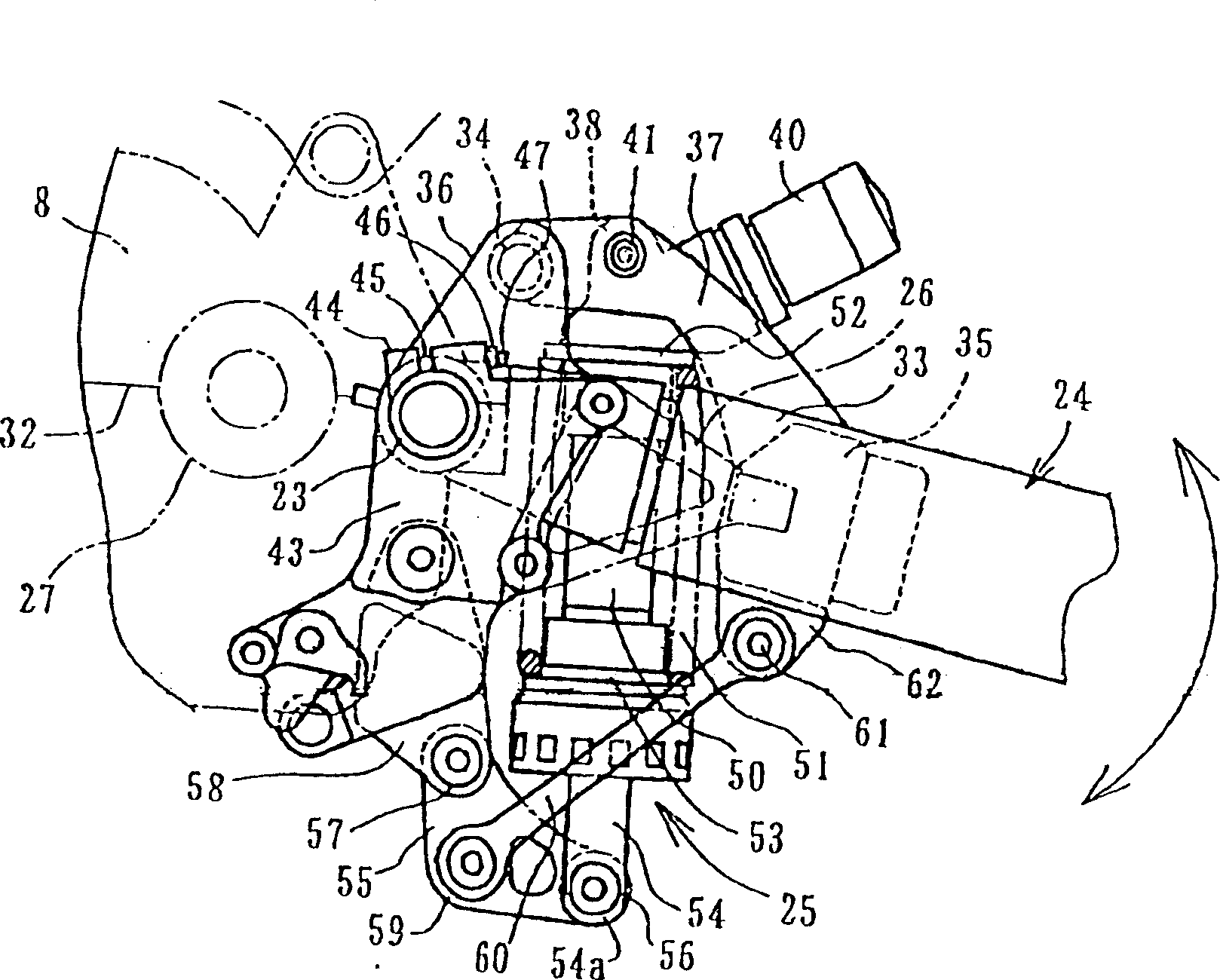

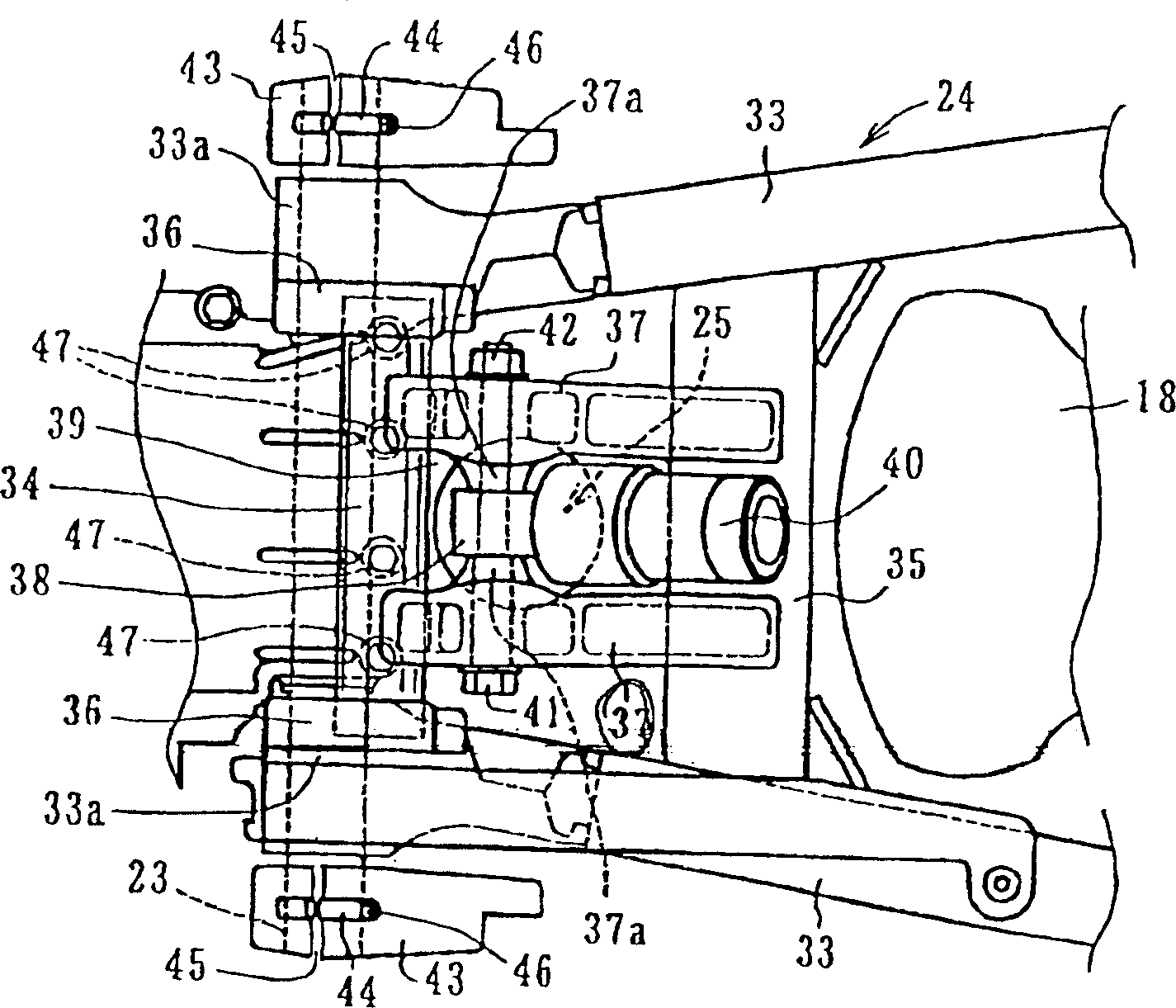

[0032] Figures 1 to 4 An example is shown in which the present invention is applied to a rear swing arm of a type supported at both ends, figure 1 is a side view showing the motorcycle according to the present embodiment; figure 2 is a side view showing the rear suspension portion; image 3 is its top view; Figure 4 is a sectional view showing a link mechanism.

[0033] figure 1 A wheel 1 , a front fork 2 , a head pipe 3 , a handlebar 4 , and a main frame 5 are shown in FIG. The main frame 5 is in the shape of a longitudinal square column, made of light alloy, bifurcated from the head pipe into left and right parts, inclined and extending downward and rearward.

[0034] Below the main frame 5, a row of four-cylinder engines 6 is supported. There are two support points: a support point 7 between the middle part of the main frame 5 and the upper part of said cylinder; and a gearbox 8 between the rear end of the main frame 5 and for constituting the engine 6 at its rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com