Dissolved oxygen monitoring sensor

A technology for monitoring sensors and dissolved oxygen, used in instruments, measuring devices, scientific instruments, etc., can solve the problems of low detection accuracy and sensitivity, small electrode surface area, damage to oxygen-permeable membranes, etc., to improve detection sensitivity, accuracy, and measurement accuracy. and high sensitivity, the effect of improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is illustrated below by way of examples and accompanying drawings.

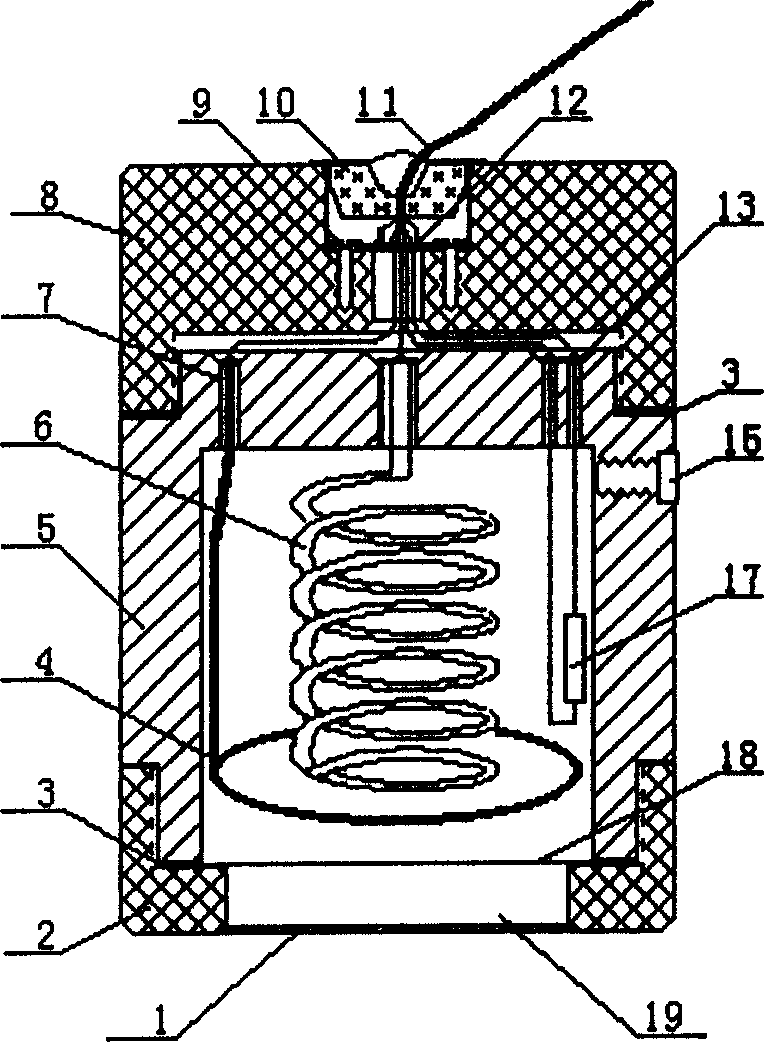

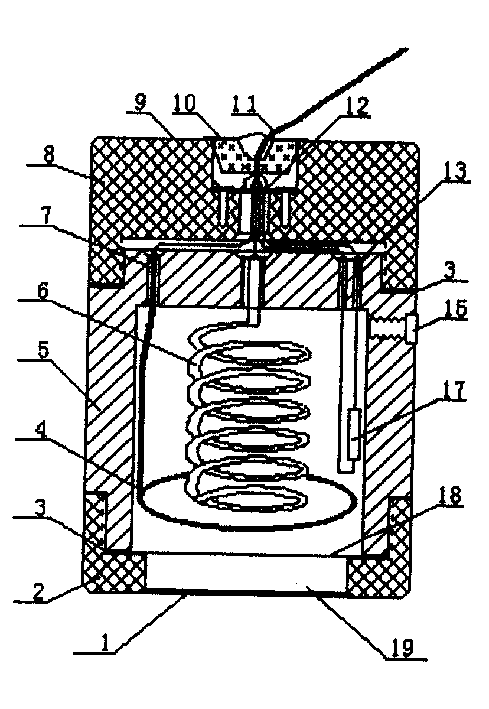

[0014] Such as figure 1 As shown, the present invention comprises filter screen 1, negative electrode 4, casing 5 with loam cake 8, anode 6, thermistor 17, oxygen-permeable film 18, wherein: casing 5 sidewalls are provided with electrolyte filling port 15, below it Oxygen-permeable membrane 18 is installed, and electrolyte solution is installed in housing 5 above oxygen-permeable membrane 18; Cathode 4, anode 6, thermistor 17 are installed in the housing 5; It is characterized in that: described anode 6 is a spiral structure, and cathode 4 is Ring-shaped and straight-line connected structures, the cathode 4, anode 6, and thermistor 17 are respectively provided at the electrode lead hole 7 with the binding post 13 on the casing 5, leaving a gap between the casing 5 and the upper cover 8 The gap and the sealed socket 12 installed on the upper cover 8 are connected with the external...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com