Optical fiber head arrangement for large power laser coupling and cooling method for optical fiber head

A cooling method and fiber optic head technology, which is applied to the coupling of optical waveguides, lasers, laser components, etc., can solve the problems of easy burning of the fiber output head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

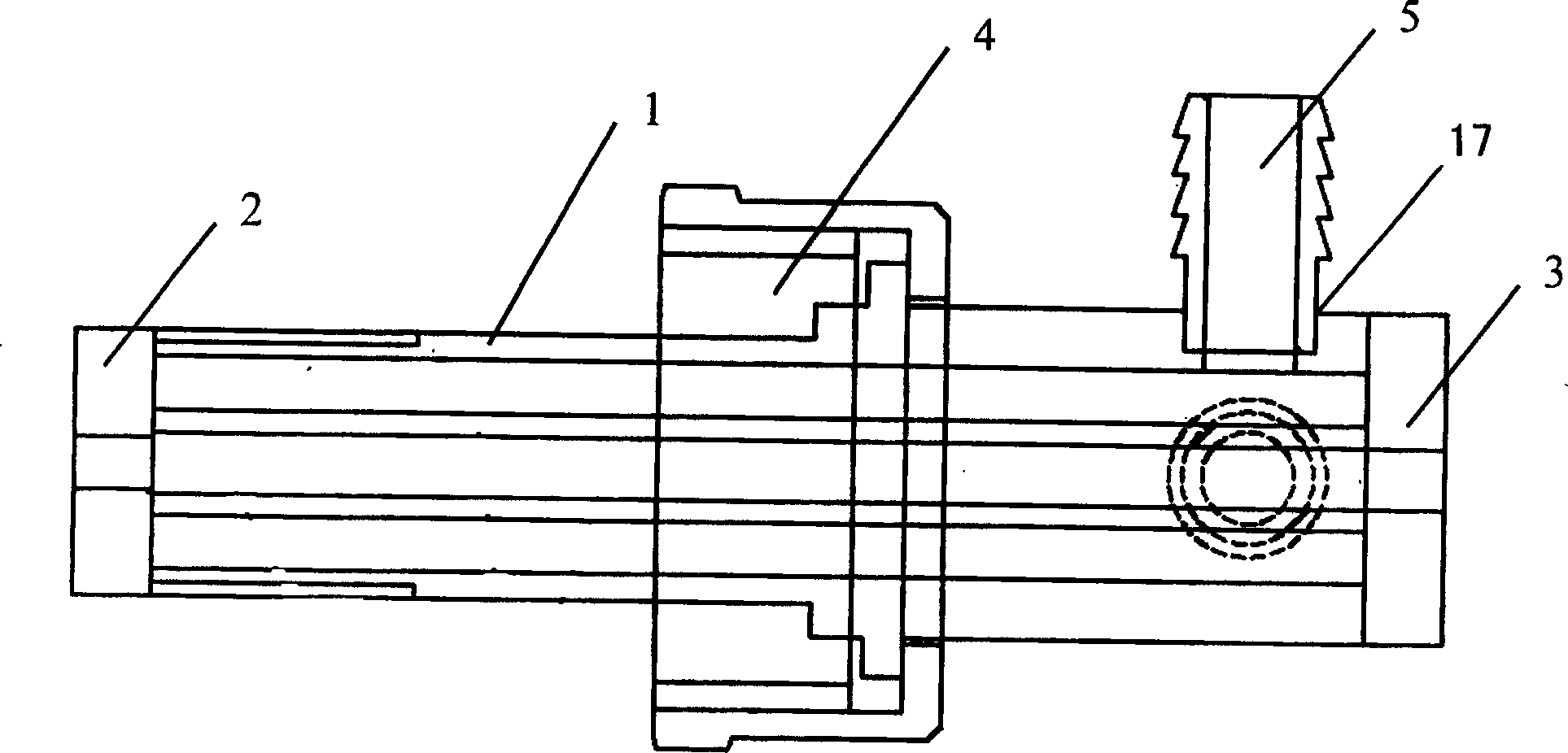

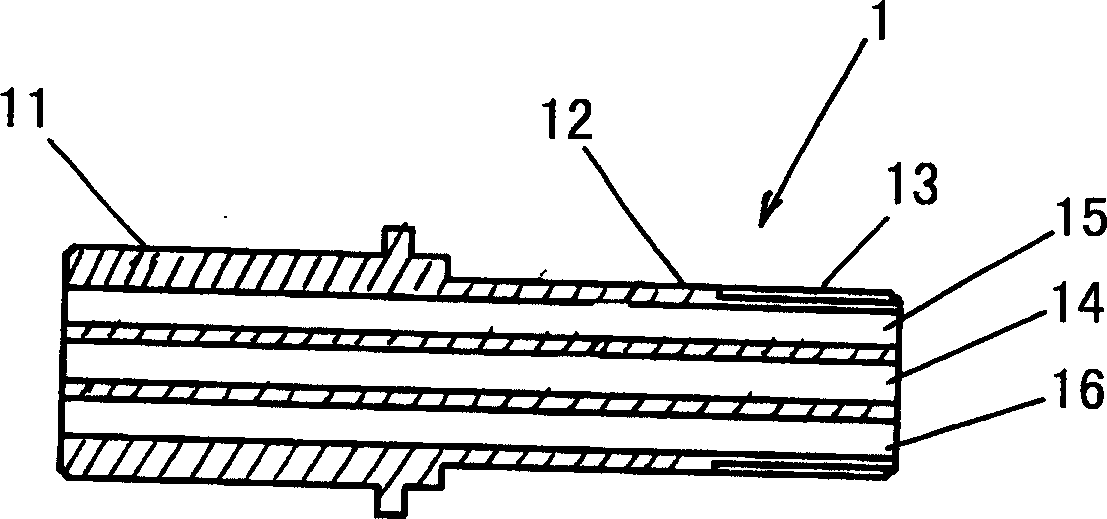

[0022] See first figure 1 and figure 2 , the present invention is a fiber head structure for high-power laser coupling, which includes: a main body 1, the main body 1 is divided into a large-diameter end 11 and a small-diameter end 12, there is a screw thread 13 at the end of the small-diameter end, and there is a Central through hole 14 is so that optical fiber is accommodated, and two through holes 15,16 are arranged on the both sides of central through hole 14, and these two through holes 15,16 are the channels of cooling water, and two water holes are arranged on large diameter end 11. Holes 17, one of the two water holes 17 communicates with the through hole 15, and the other communicates with the through hole 16;

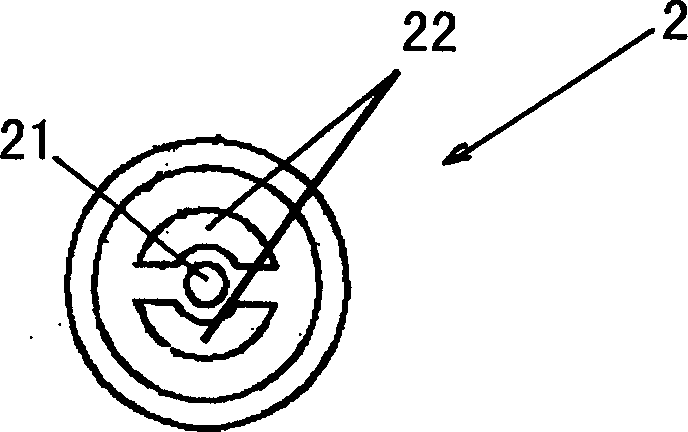

[0023] see figure 1 image 3 and Figure 4 , a front plug 2, a rear plug 3, the front and rear plugs 2, 3 have the same structure; the center of the front plug 2 has a through hole 21, and there are two holes on both sides of the through hole 21 and two o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com