Gas apray generating apparatus

A technology for generating devices and aerosols, which is used in spray devices, liquid spray devices, maintenance and safety accessories, etc., and can solve problems such as the inability to apply the minimum amount and the difficulty of increasing the diameter of the oil hole.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

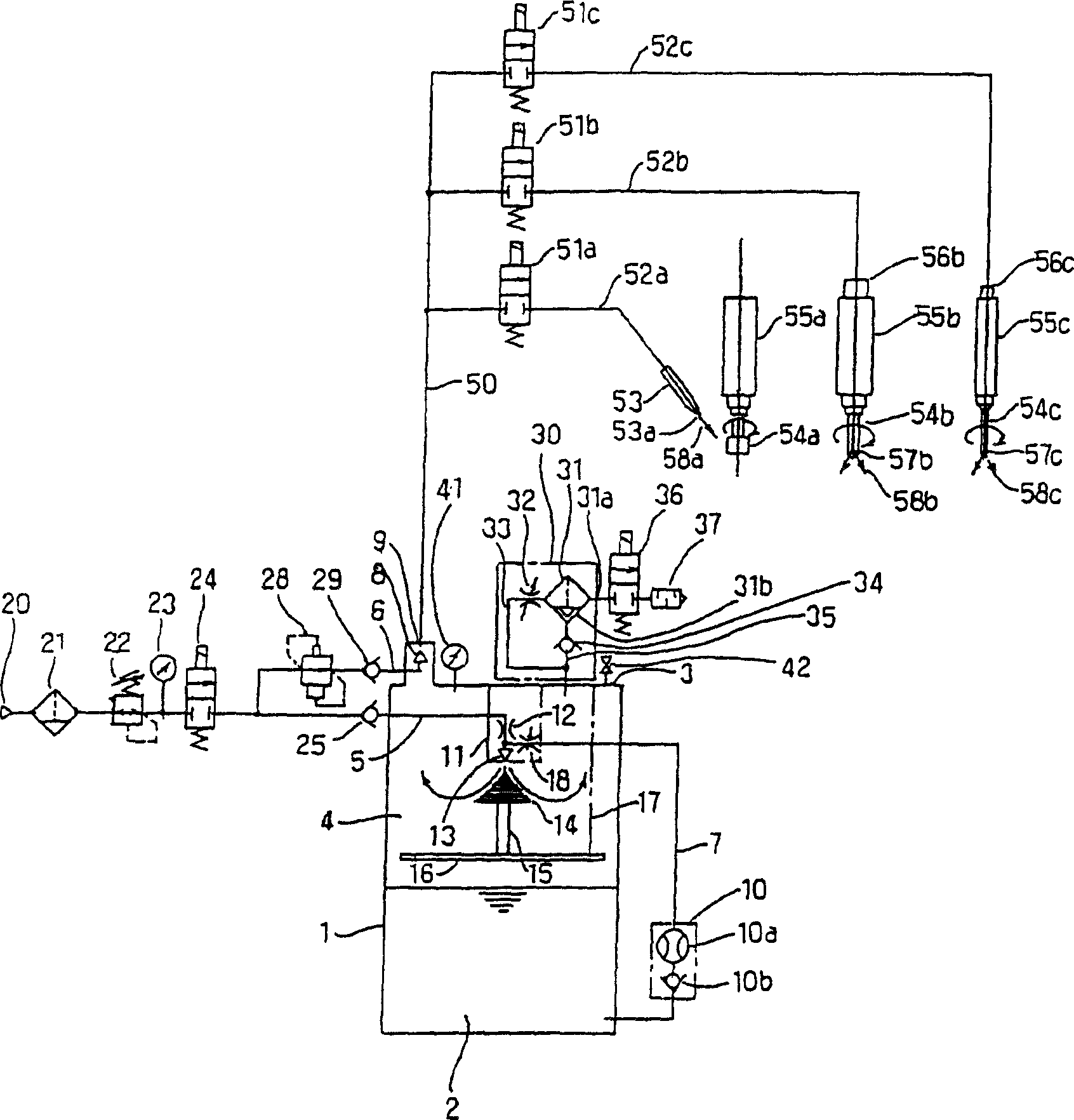

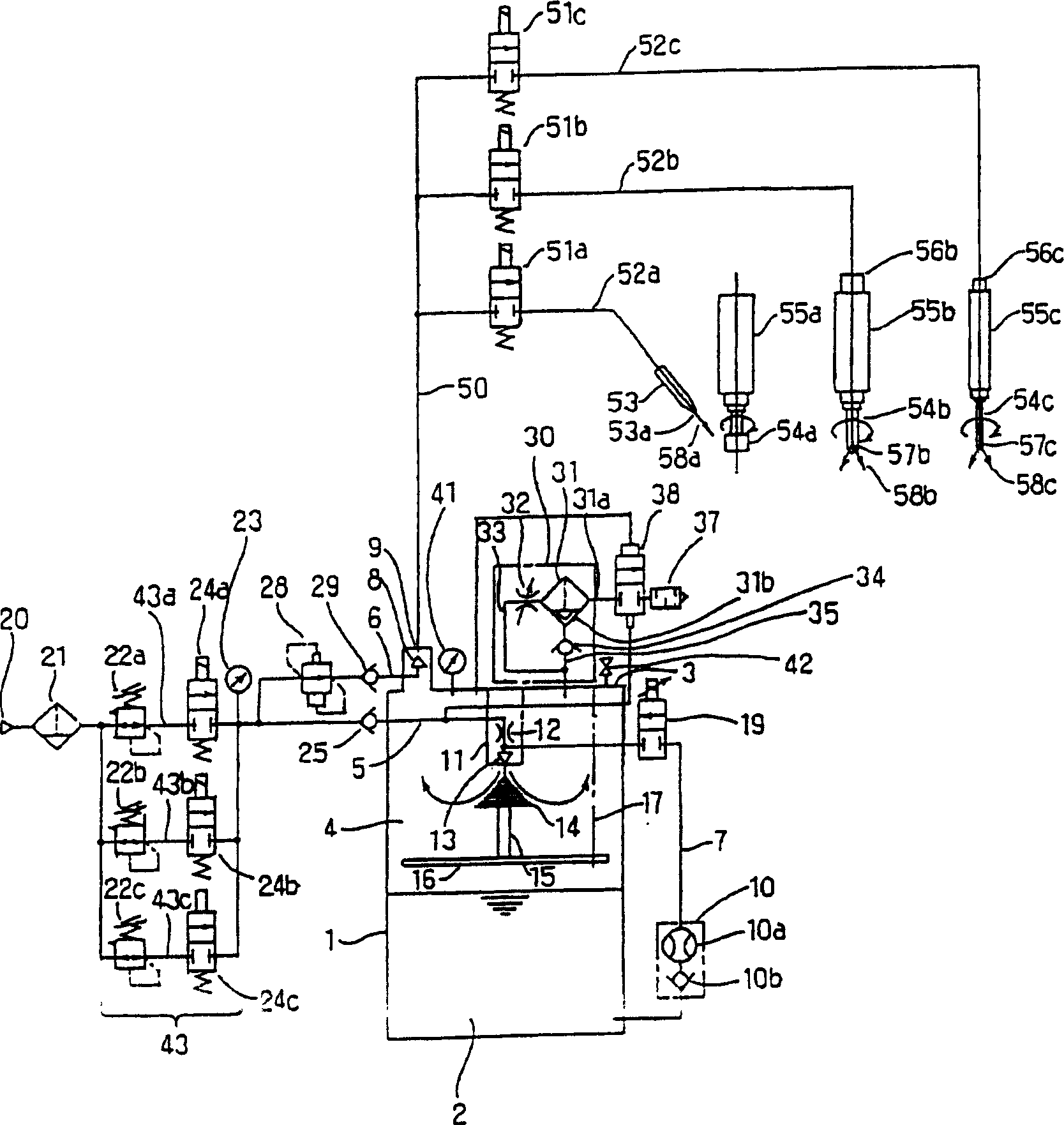

[0059] figure 1 Shown is the schematic structure of the gas mist generating device according to the first embodiment of the present invention. This aerosol generating device includes a container 1 in which a liquid supply source (oil source) 2 for supplying a liquid cooling lubricant such as oil, for example, is accommodated in a lower portion thereof. The container 1 constitutes a pressure container covered by a lid 3. In the space 4 of the container 1 formed above the oil source 2, the ejector 11 is fixedly installed on the cover 3 and receives the supply of pressurized air (gas) and oil (liquid), and the mist ejected from the ejector 11 stays In space 4. The supply of pressurized air (gas) from the ejector 11 is performed through the gas supply passage 5. When the pressurized air passes through the throttle 12 provided in the ejector 11, the cross-sectional area increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com