Resistant touch screen with variable resistance layer

A touch screen, resistive technology, applied in the field of forming a resistive layer, can solve the problems of high cost, high temperature, and high cost of silver ink, and achieve the effects of large effective area, cost reduction, and simple manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

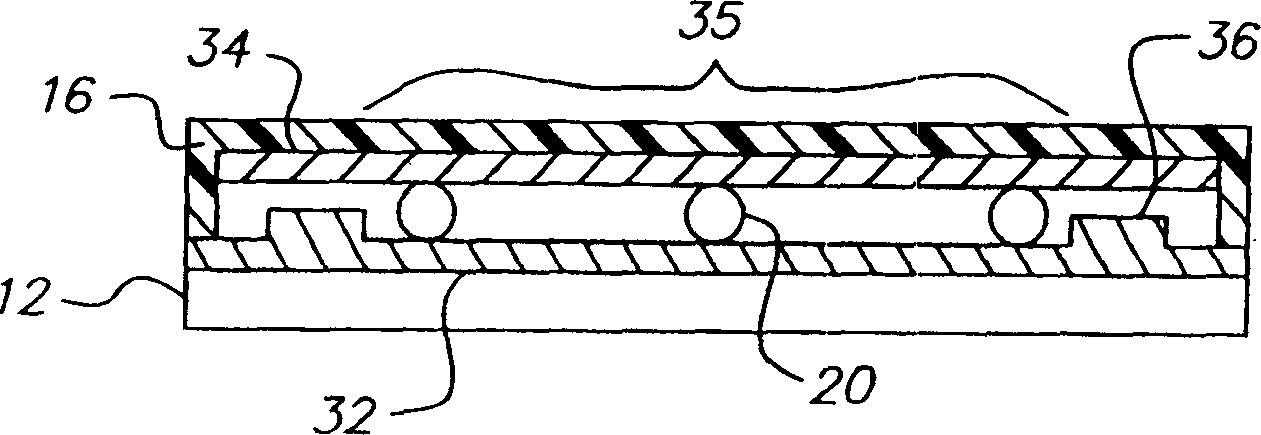

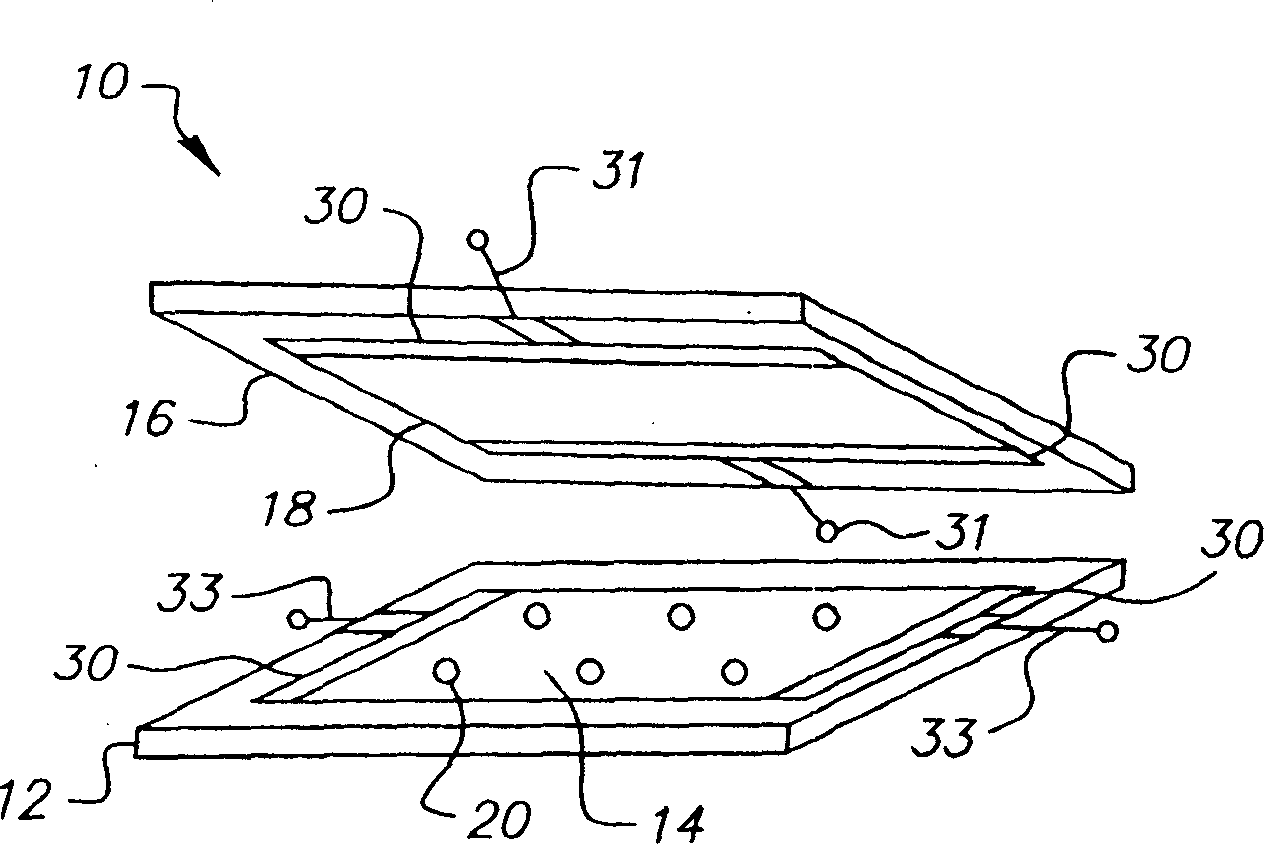

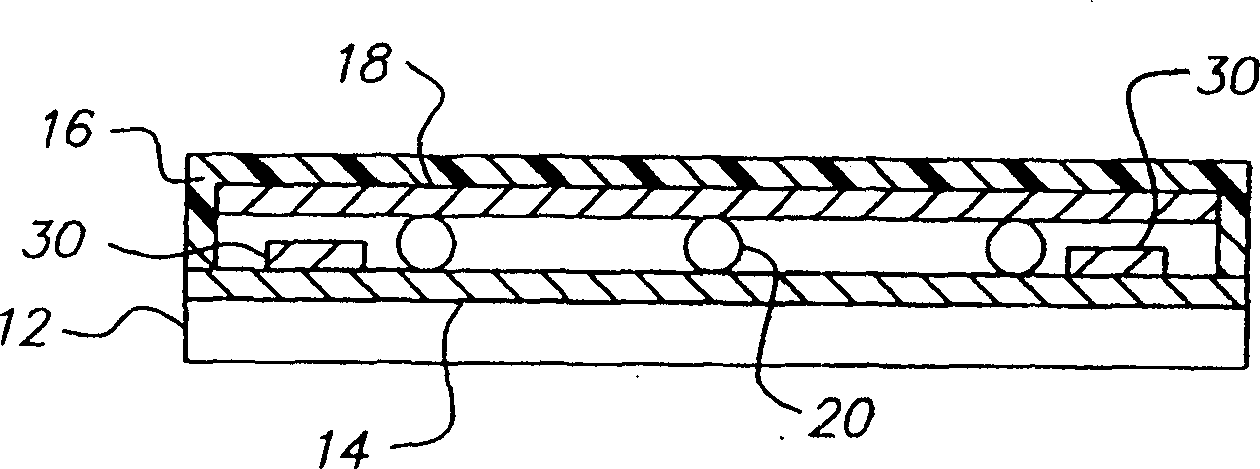

[0018] refer to figure 1 , by using a variable conduction layer 32 disposed on the substrate 12 to overcome the problems of prior art touch screens. The flexible transparent cover sheet 16 having the second conductive layer 34 is separated from the variable conductive layer 32 by conventional means such as isolation points 20 . The conductivity of the conductive layer 32 disposed on the substrate 12 and / or the conductive layer 34 disposed on the flexible transparent cover sheet 16 is variable.

[0019] The change in conductivity of variable conduction layers 32 and / or 34 may be continuous or discontinuous. If the conductivity of the layer is continuous, the sheet resistance of the layer varies continuously and gradually between locations within the layer. If the conductivity of the layer is discontinuous, a particular location within the layer will have a significantly different conductivity than nearby locations.

[0020] In the prior art touch screen, the sheet resistance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com