System of using soft spberical particles to proceed membrane cleaning and its cleaning method

A spherical particle and membrane cleaning technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as low cleaning efficiency, generation of cleaning waste liquid, and limited cleaning effect, so as to restore flux and solve The effect of membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention mainly provides a membrane cleaning system and cleaning method using soft spherical particles. In a specific embodiment, the soft spherical particles are sponge balls.

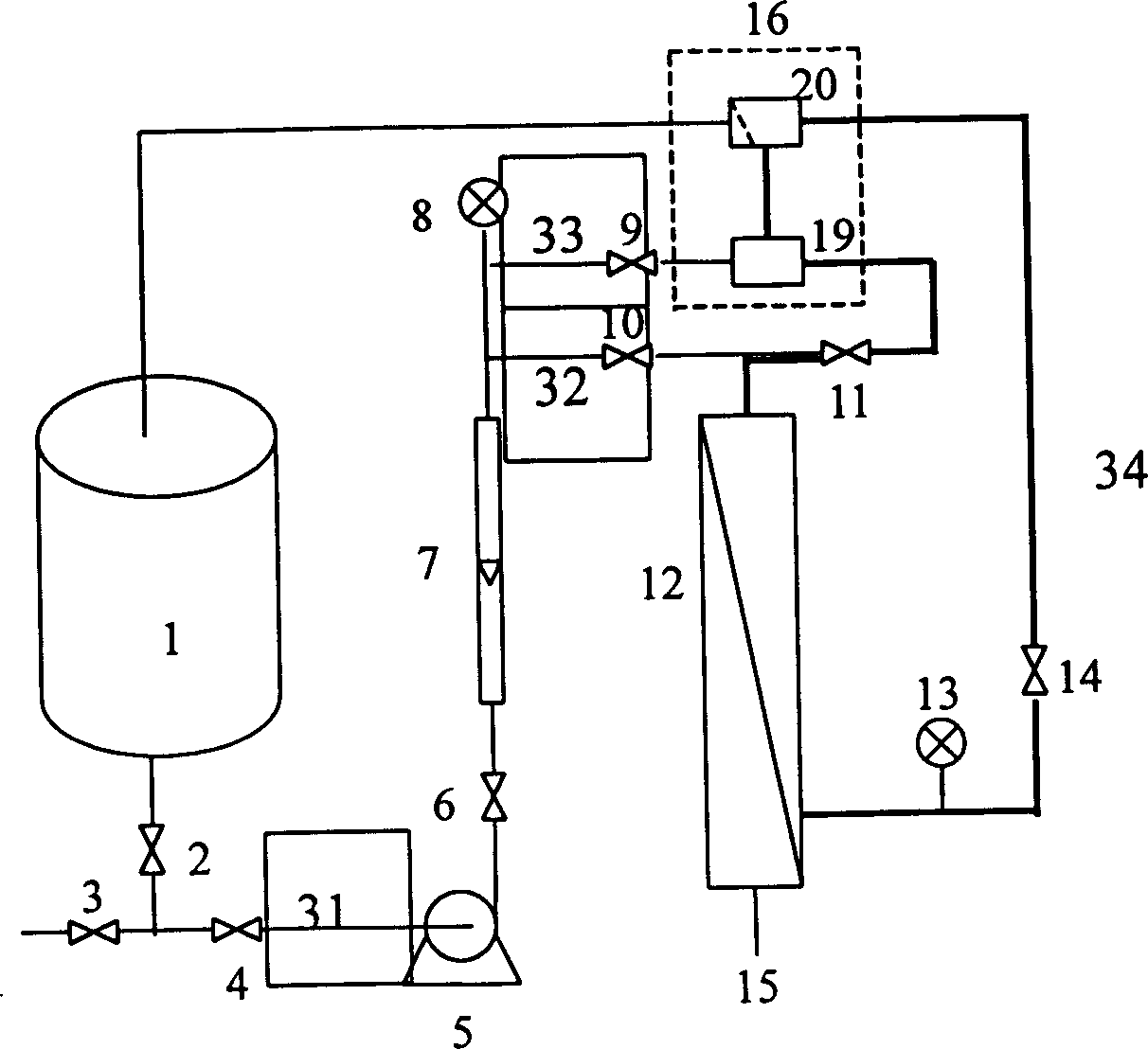

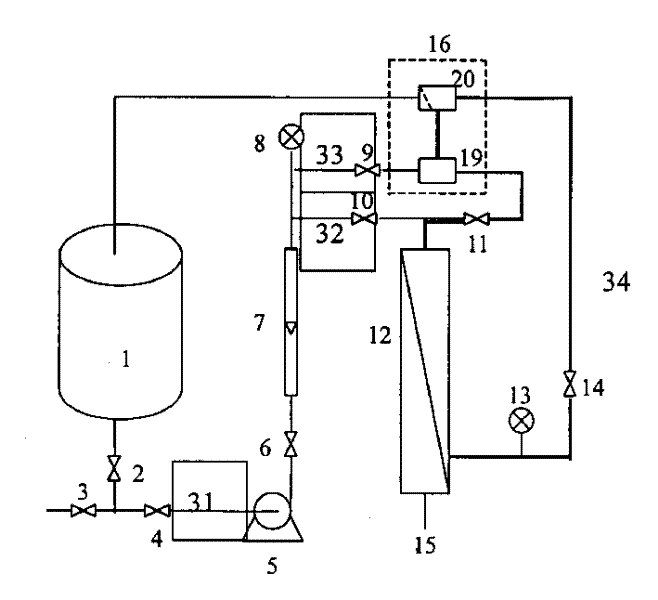

[0019] Such as figure 1 As shown, the tubular membrane solid-liquid two-phase flow cleaning system mainly includes: circulation tank 1, main liquid flow supply flow path 31, membrane supply flow path 32, cleaning supply flow path 33, tubular membrane 12, return flow path 34, Pellet Circulator 16.

[0020] One end of the main liquid supply channel 31 is connected to the outlet of the circulation tank 1 , and the other end is connected to the membrane supply channel 32 and the cleaning supply channel 33 . Wherein, one end of the above-mentioned membrane supply flow path 32 is connected to the above-mentioned main liquid flow supply flow path 31, and the other end is connected to the inlet end of the tubular membrane 12, which is used to supply the above-mentioned main liquid flow to the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com