Sewing machine

A sewing machine and needle bar technology, applied to sewing machine components, sewing machine needle seats, sewing equipment, etc., can solve problems such as vibration, noise, difficulty, and complex structure of the sewing machine arm, and achieve stable reciprocating rotation and simplified structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

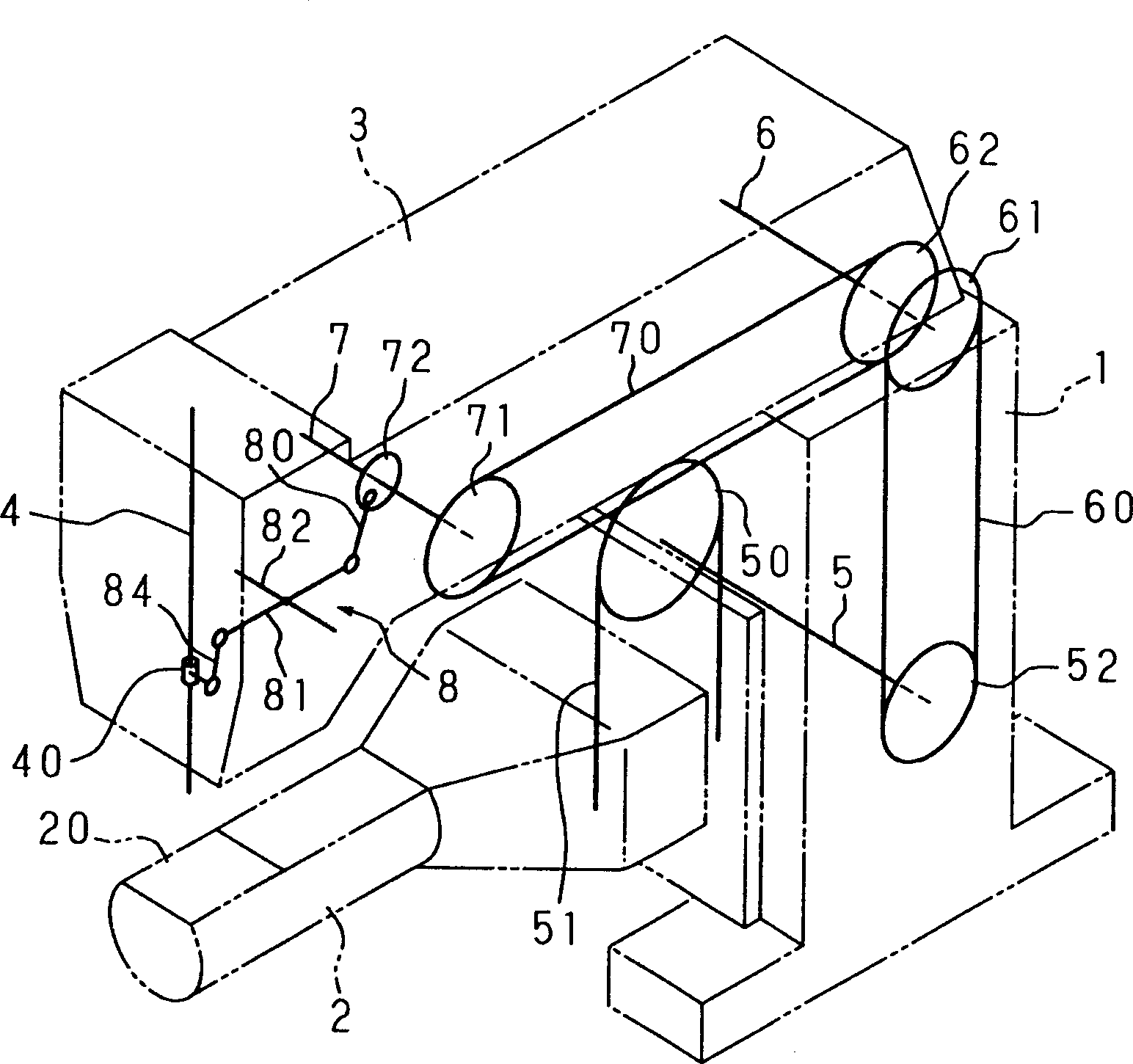

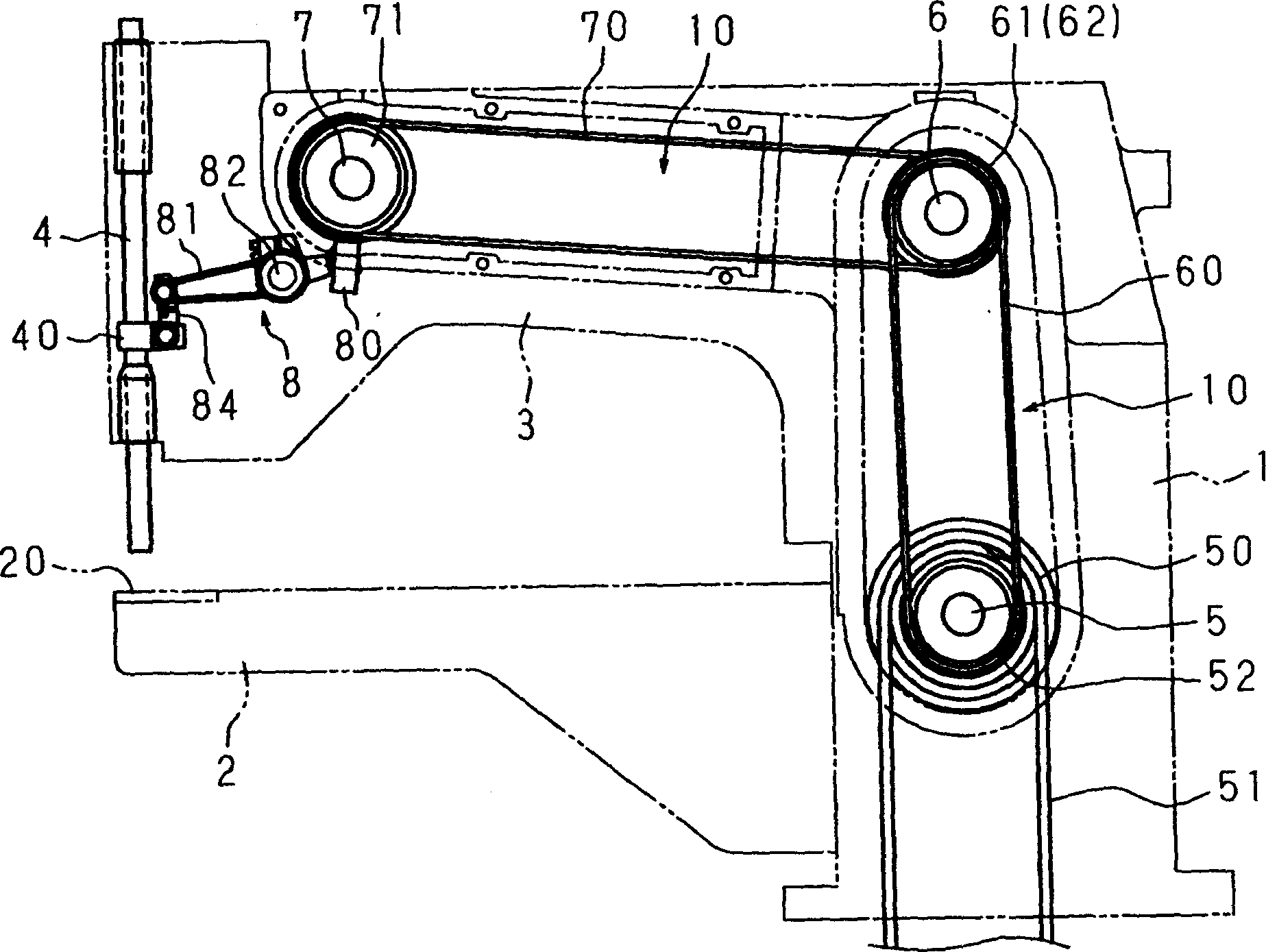

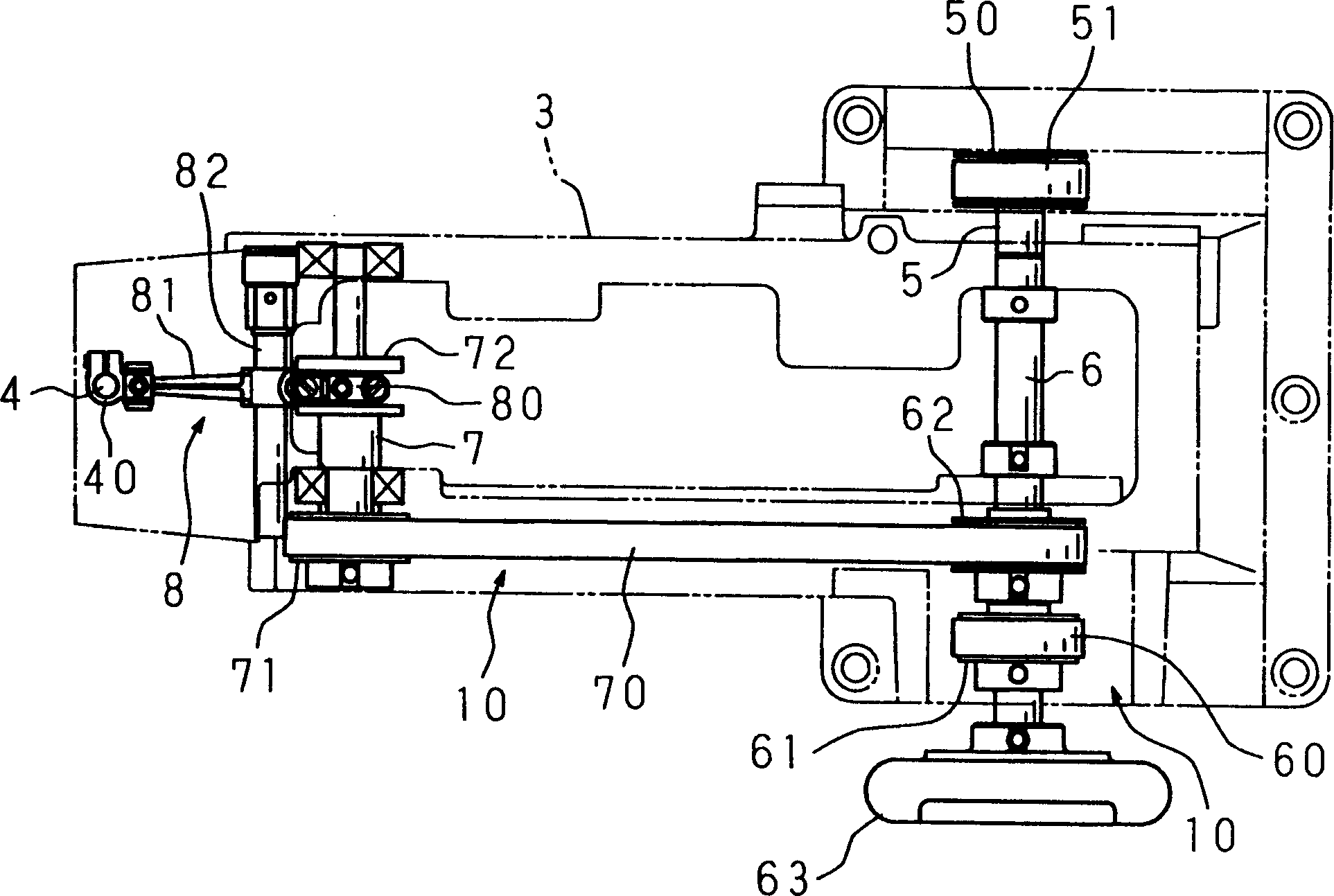

[0037] Hereinafter, the present invention will be described in detail based on the drawings showing the embodiments. figure 1 It is a perspective view showing the overall structure of the transmission mechanism of the needle bar in the sewing machine of the present invention together with the appearance of the sewing machine. In the illustrated sewing machine, the cylindrical base 2 is protruded from the lower part of the sewing machine body 1, and at the upper part on the same side, the sewing machine arm 3 is projected slightly parallel to the cylindrical base 2, thereby forming a straight cylindrical sewing machine.

[0038] This sewing machine has a feeding device and a yarn bending wheel (not shown) under the needle plate 20 mounted on the front end of the cylindrical base 2, and also has a needle bar 4 suspended and supported on the front end of the sewing machine arm 3. , a needle not shown is installed at the lower end of the needle bar 4 . In addition, at the front e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com