Fluorescent lamp and lighting device

A fluorescent lamp and light-transmitting technology, applied in the field of fluorescent lamps and lighting devices, can solve problems such as coloring, phosphor film peeling, and appearance deterioration, and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

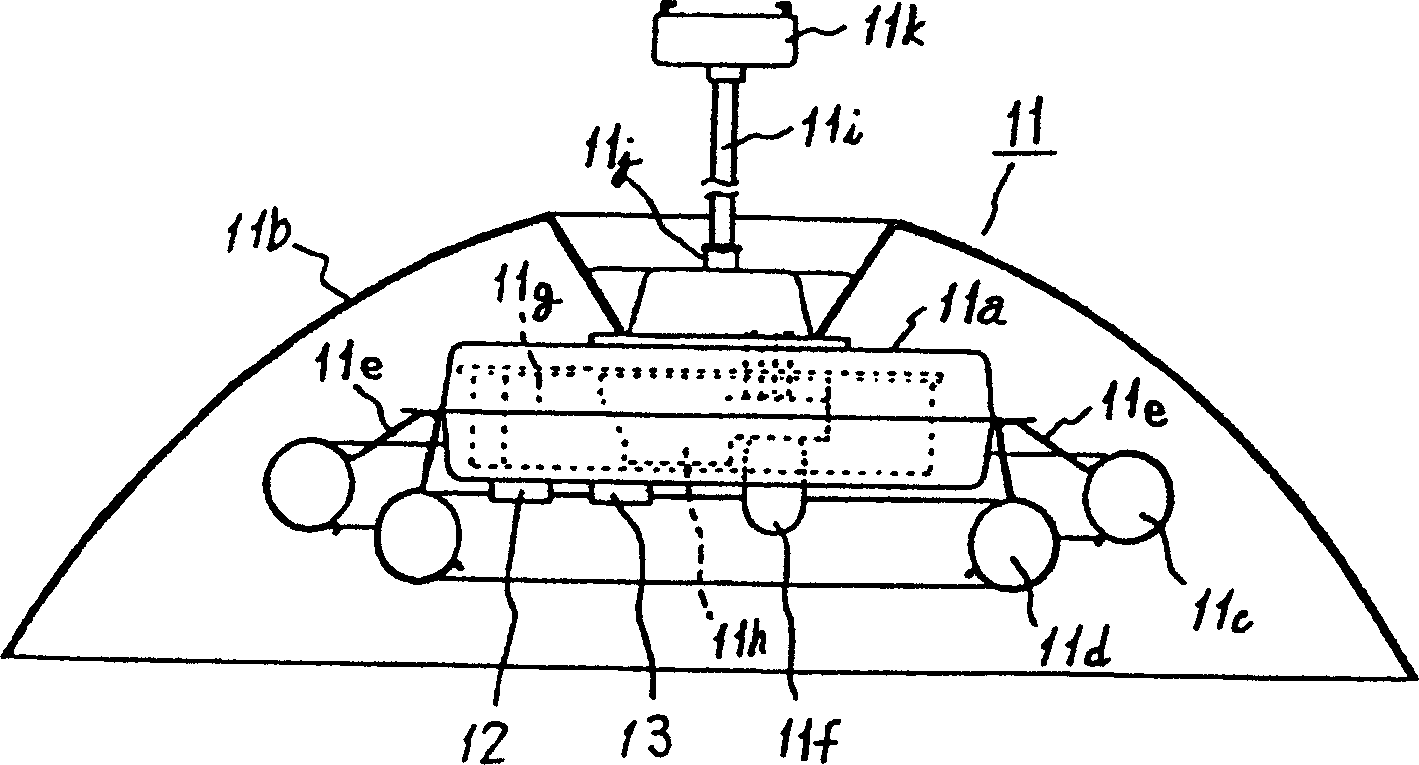

[0067] Embodiments of the present invention will be described below with reference to the drawings.

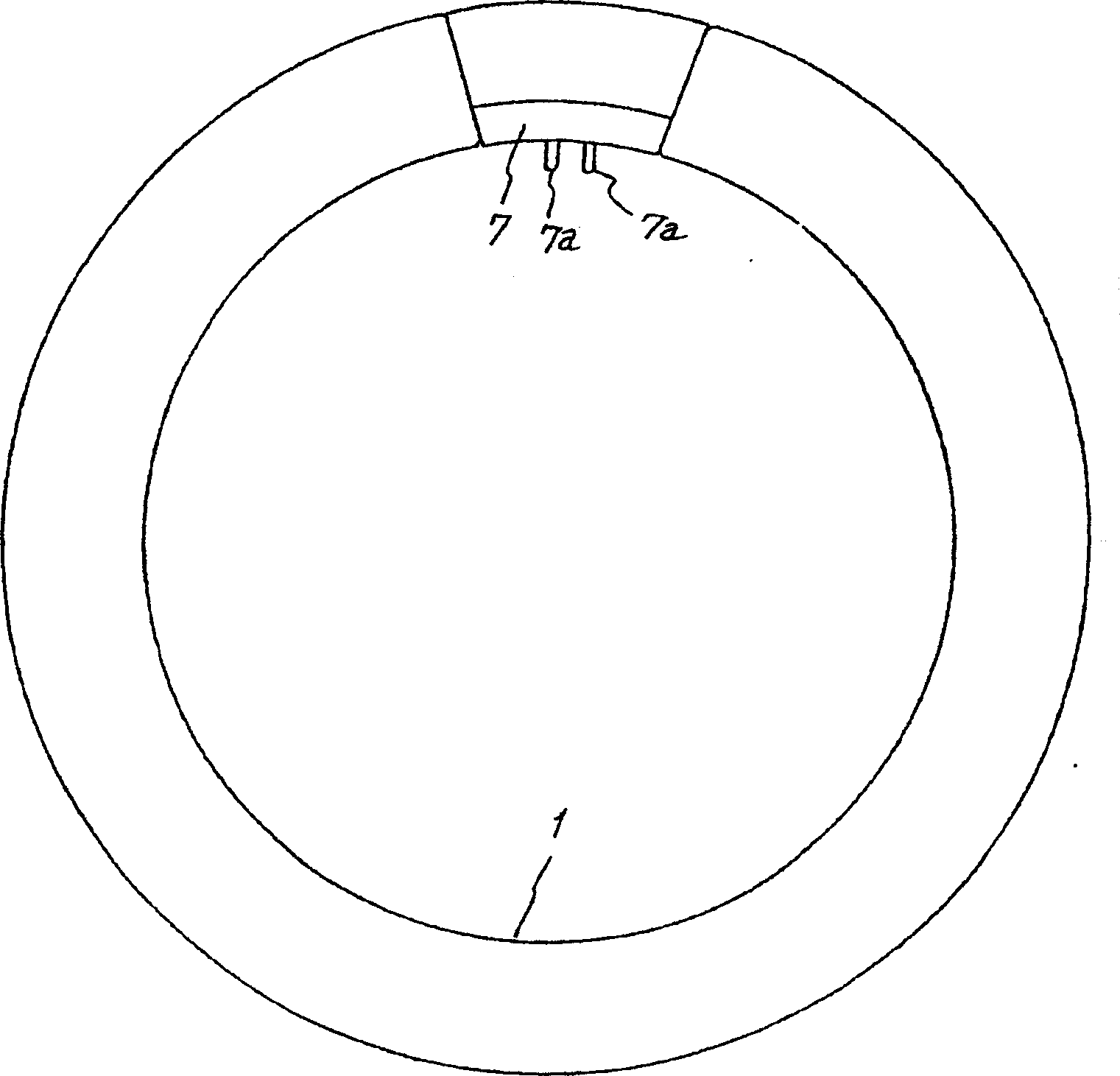

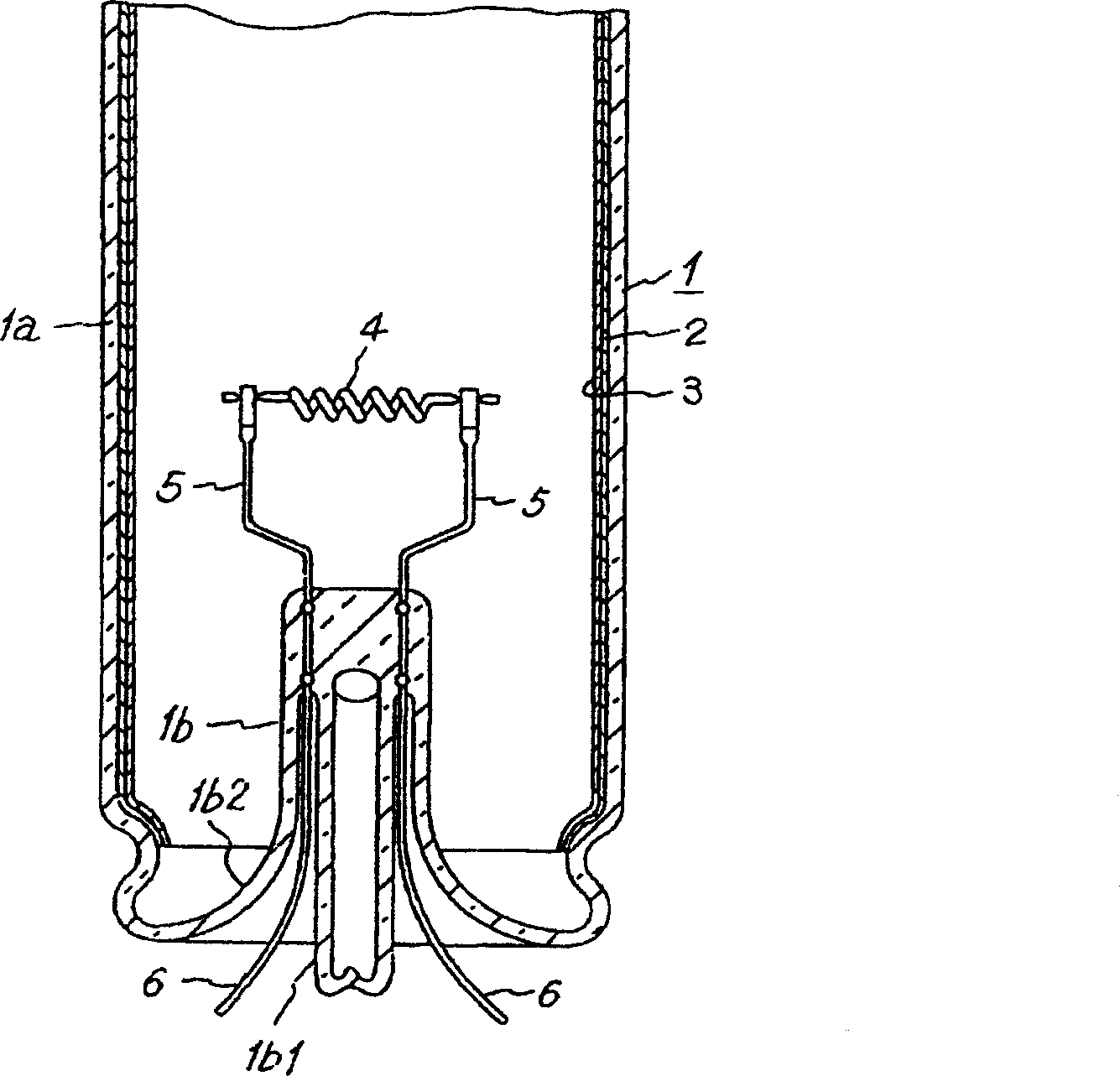

[0068] figure 1 Shown is a partially cutaway front view of one embodiment of the fluorescent lamp of the first embodiment, figure 2 An enlarged side sectional view of the end of the same tube. In each figure, 1 is a translucent discharge vessel, 2 is a protective film, 3 is a phosphor layer, 4, 4 is a pair of electrodes, 5, 5 are internal lead-in lines, 6, 6 are external lead-in lines, 7 For the lamp holder. The fluorescent lamp of this embodiment is a ring fluorescent lamp. in addition, figure 2 The non-exhaust-side end of the light-transmitting discharge vessel 1 before bending is enlarged and shown.

[0069] The light-transmitting discharge vessel 1 is composed of a glass tube 1a and a pair of horn-shaped stems 1b, 1b. The glass tube 1a is made of soda lime glass. A pair of horn-shaped stems 1b are welded to both ends of the glass tube 1a to form a sealing portion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com