Light source of back light module

A backlight module and light source technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as insufficient uniformity of white light, and achieve the effect of shortening the distance and fully mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above and other purposes, features, and advantages of the present invention more comprehensible, a preferred embodiment is specifically cited below, and in conjunction with the accompanying drawings, the detailed description is as follows:

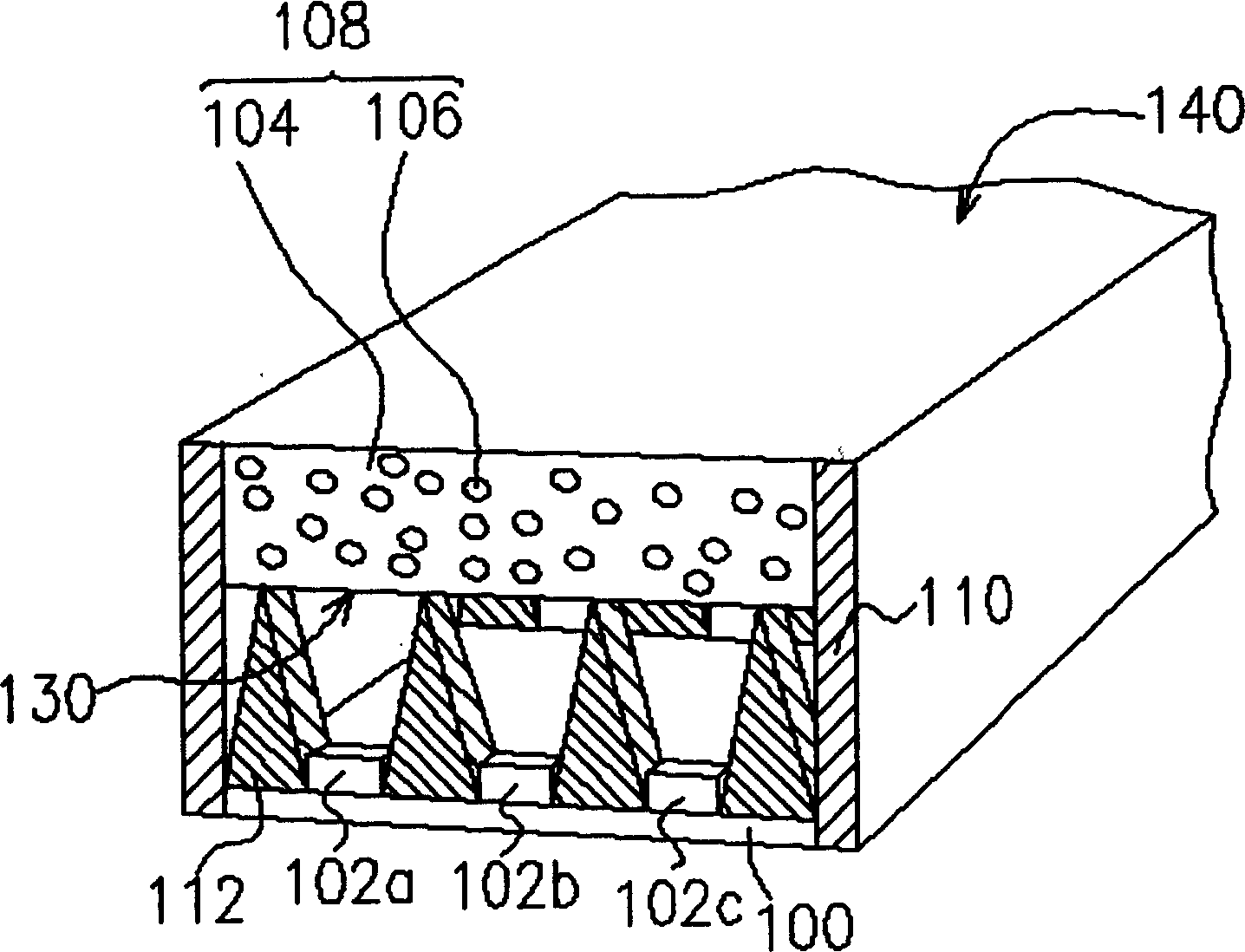

[0032] Please refer to figure 1 , which is a schematic diagram of a light source of a backlight module according to the first preferred embodiment of the present invention. The light source of the backlight module of this embodiment includes several light emitting diodes 102 a , 102 b , 102 c , a diffusion device 108 , several support members 112 and a reflector 110 .

[0033] Wherein, the LEDs 102a, 102b, 102c are arranged on a carrier 100, and the carrier 100 is preferably a reflective carrier. As for the LEDs 102a, 102b, and 102c arranged on the carrier 100, the number and manner of their arrangement are determined according to actual needs. The light emitting diodes 102a, 102b, 102c are, for example, red (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com