Preparation and using method of steel slag colorful pavement brick with water penetrating function

A kind of pavement brick and color technology, which is applied in the direction of paving, roads, roads, etc., which are paved with prefabricated blocks, can solve the problems of management cost, land occupation, environmental pollution, etc., and achieve the goal of protecting the environment, saving energy and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

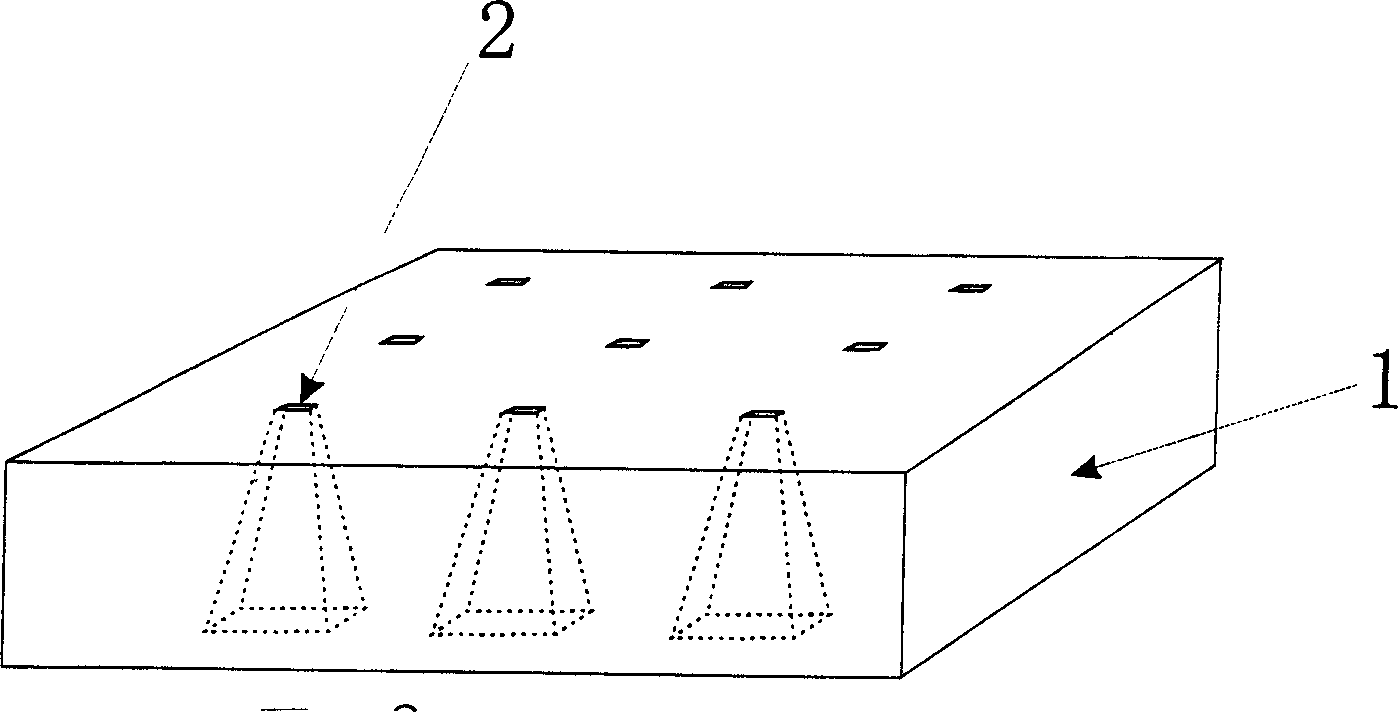

Image

Examples

Embodiment Construction

[0018] 1. Red pigment is mixed with No. 42.5 ordinary Portland cement to make dark red Portland cement, wherein red pigment accounts for 2.0wt.%, and ordinary Portland cement accounts for 98wt.%. The above-mentioned mixed colored cement is first covered with the bottom of the mold according to 10.0wt.% of the total cement consumption. Mix No. 42.5 ordinary Portland cement and 0-15mm steel slag sand at a ratio of ash / sand ratio 0.30 / 1, and then add tap water. The ratio of water / ash is 0.50 / 1. Vibration molding after stirring evenly. The hole density of the adobe is 3 holes / 100cm 2 , The permeable brick belt mold was cured for one day at 20°C and 90% humidity, and then demoulded and soaked in water for 27 days. The various properties are shown in Table 1.

[0019] Compressive strength

(MPa)

(MPa)

Compressive strength after 25 freeze-thaw cycles (MPa)

Permeability

(ml / cm 2 ·Second)

41.9

3.3

33.6

1.211 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com