Electric energy quality controller for traction transformer station

A traction substation, power quality technology, applied in electrical components, circuit devices, AC network circuits, etc., can solve the problems of system instability, high grid voltage, high cost, reduce total capacity, excellent compensation performance, eliminate The effect of negative sequence current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

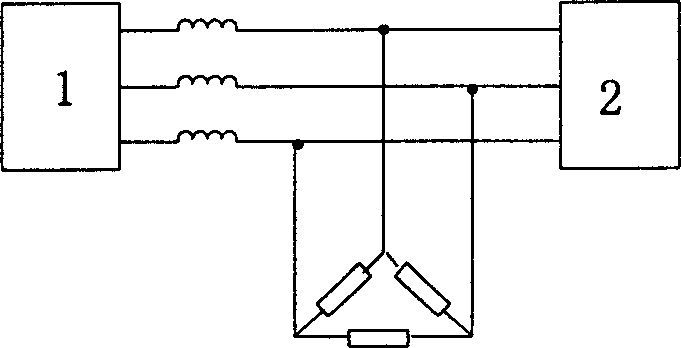

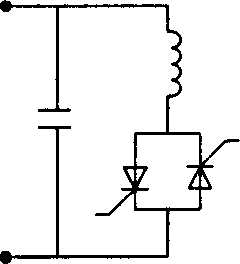

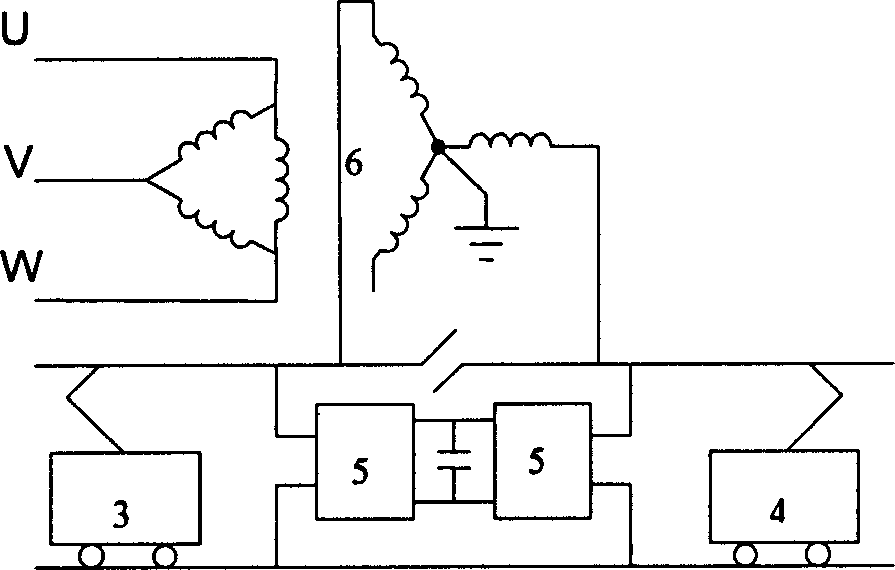

Method used

Image

Examples

Embodiment

[0034] The embodiment of the present invention provides a test prototype of a power quality controller, and its main technical indicators are: (1) The power supply voltage is 220V / 50Hz, and the short-circuit capacity is 770KVA. (2) The three-phase converter consists of a voltage type inverter with a capacity of 10kVA. The isolation transformer is a Scott transformer with a capacity of 3kVA. (3) In the test device, the capacity of the balance transformer is 3kVA, the three-phase line voltage on the primary side of the transformer is 220V, and the two-phase voltage on the secondary side is 110V respectively. The load is a diode rectified load filtered by a smoothing reactor, which can simulate a traction load.

[0035] Actual operation results and simulation results show that the power quality controller proposed by the present invention can effectively compensate the harmonics, reactive power and negative sequence current in the traction grid, and the filtering effect of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com