Eccentric multi-axial multi-cutter type tunnelling machine

A multi-cutter and roadheader technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as easy wear of cutters, large sliding distance of cutting heads, unfavorable long-distance tunneling, etc., and achieve the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

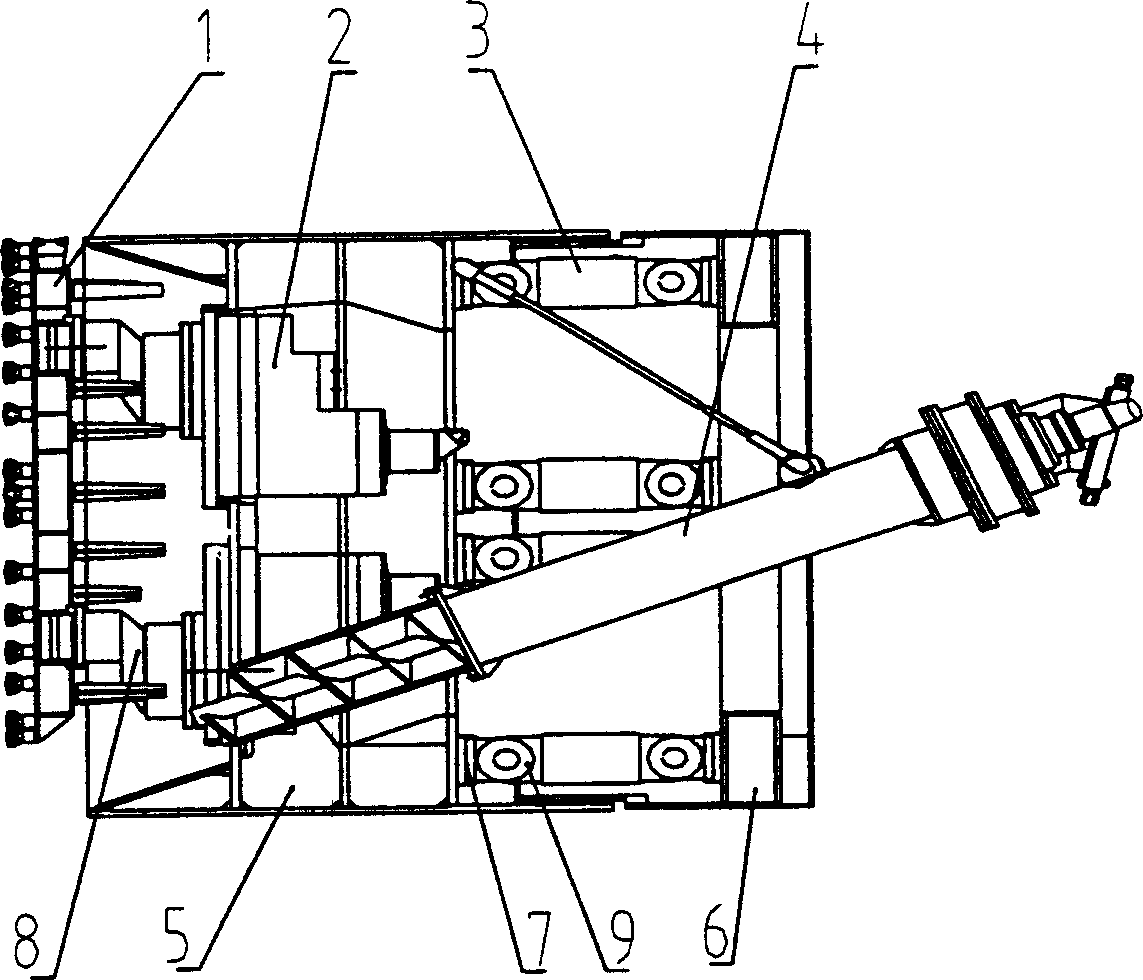

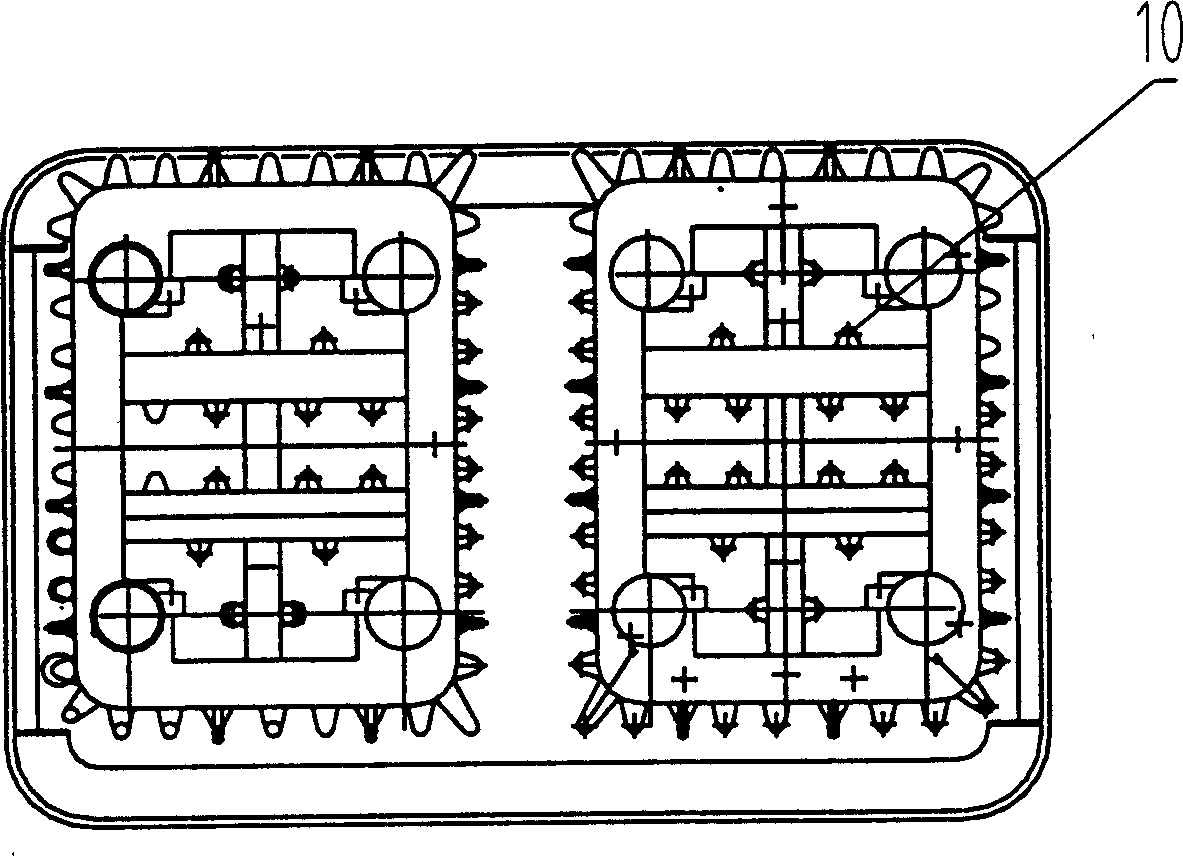

[0011] Such as figure 1 , figure 2 As shown, the present invention includes: cutting cutterhead 1, cutterhead drive 2, deviation correction device 3, screw conveyor 4, front section casing 5, rear section casing 6, base 7, eccentric shaft 8, and its connection mode is: cutting The cutterhead 1 is composed of two left and right cutterheads, which are located at the front end of the jacking pipe. Each cutterhead is connected to the four eccentric shafts 8 in the cutterhead drive system 2 through bolts, and the two screw conveyors 4 are respectively installed through bolts. On both sides of the front housing, the base 7 under the deviation correction device 3 connects the front housing 5 and the rear housing 6 .

[0012] Two oil cylinders 9 in the deviation correction device 3 are used as a group, and the two sides of each oil cylinder 9 are respectively fixed on the base 7 by pins, and the bases 7 on both sides are respectively welded to the front shell 5 and the rear shell 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com