Mother technique of discrete digit constant energy wave chopping and current transformation

A constant energy, digital technology, applied in the direction of converting DC power input to DC power output, adjusting electrical variables, instruments, etc., can solve sub-technical congenital disabilities, reliability requirements are not too high, and it is difficult to coordinate and solve chopper power , chopping frequency and device stress, to achieve the effect of improving the design range and comprehensive performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

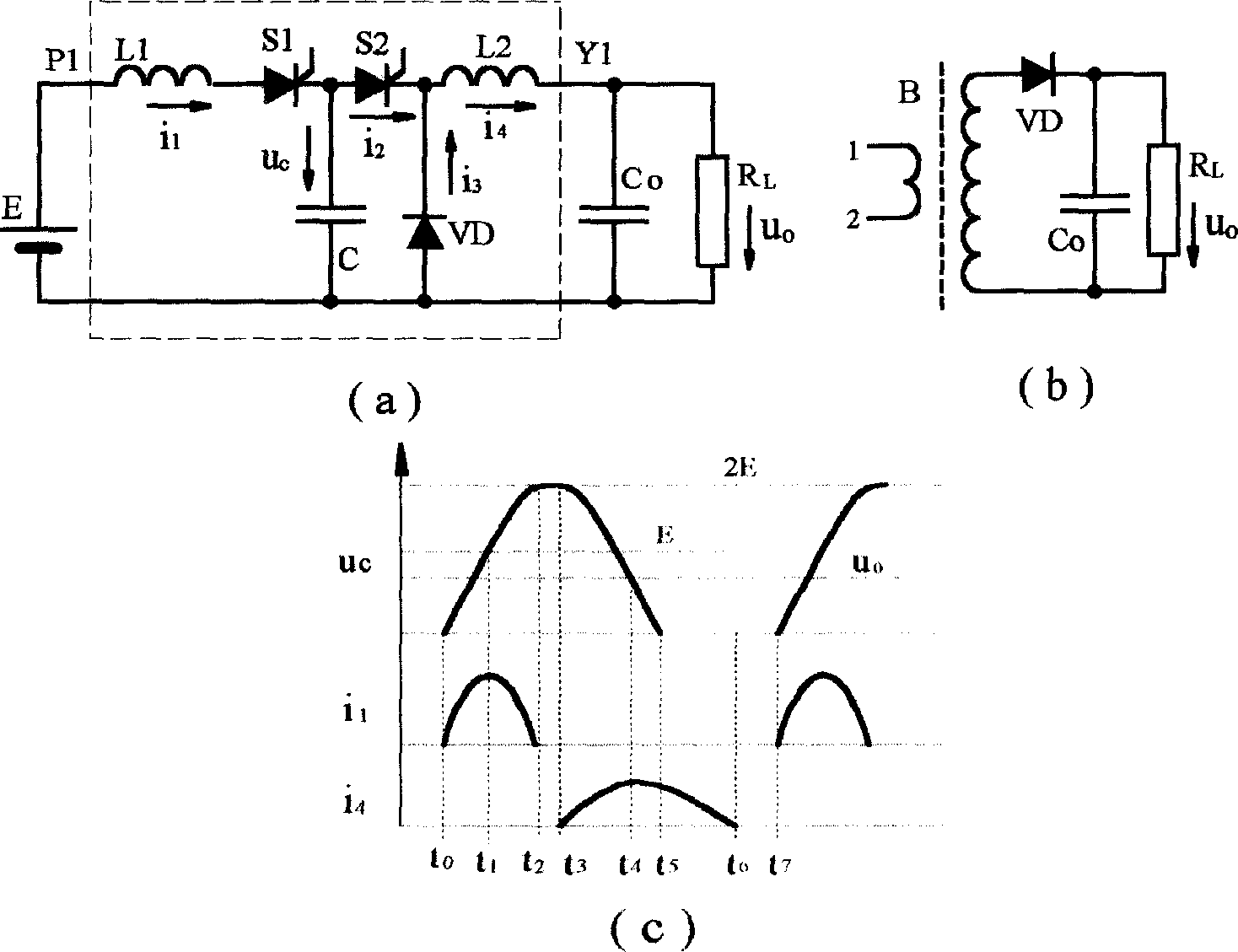

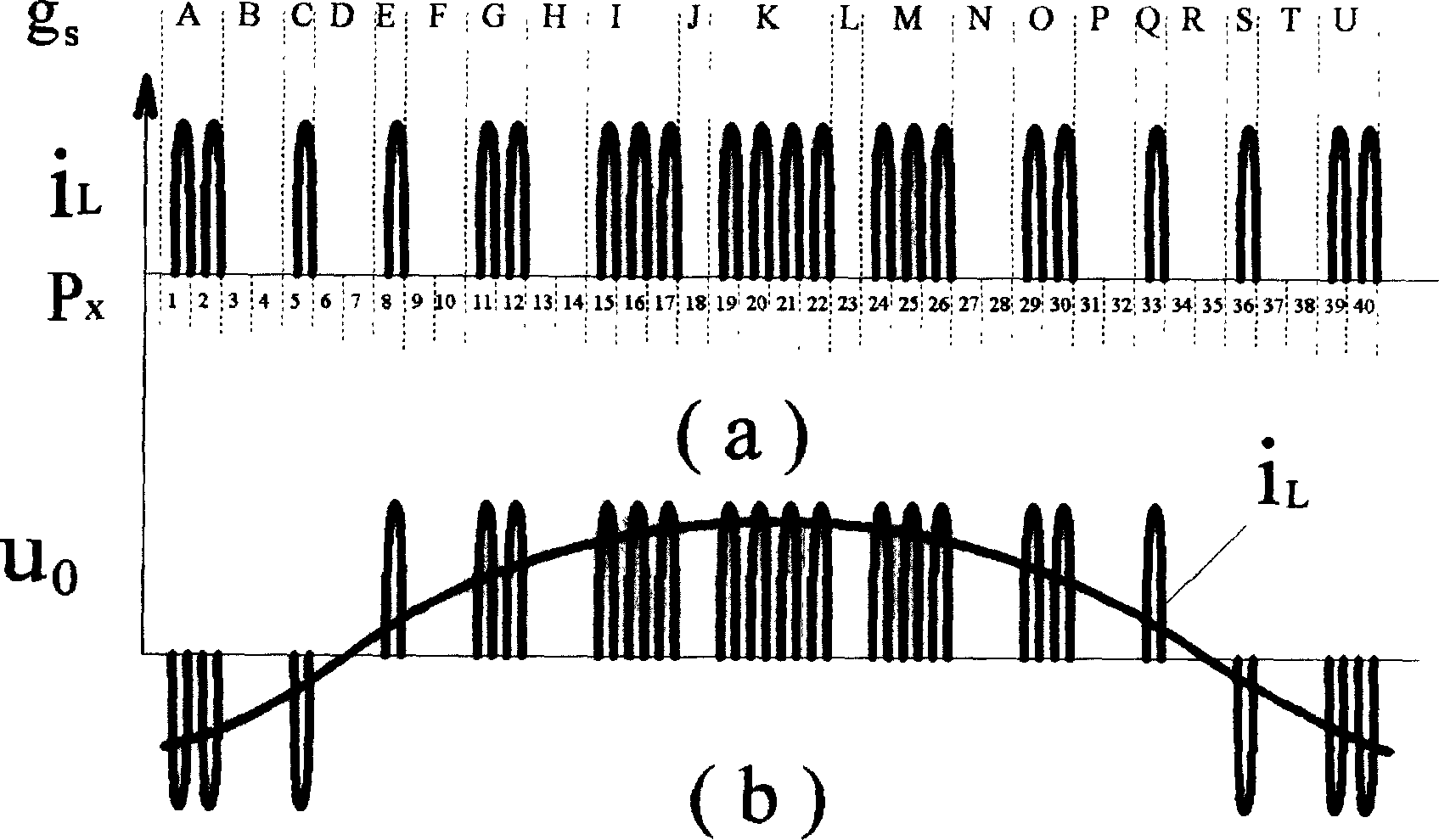

[0020] 1. The composition of the power pulse forming circuit

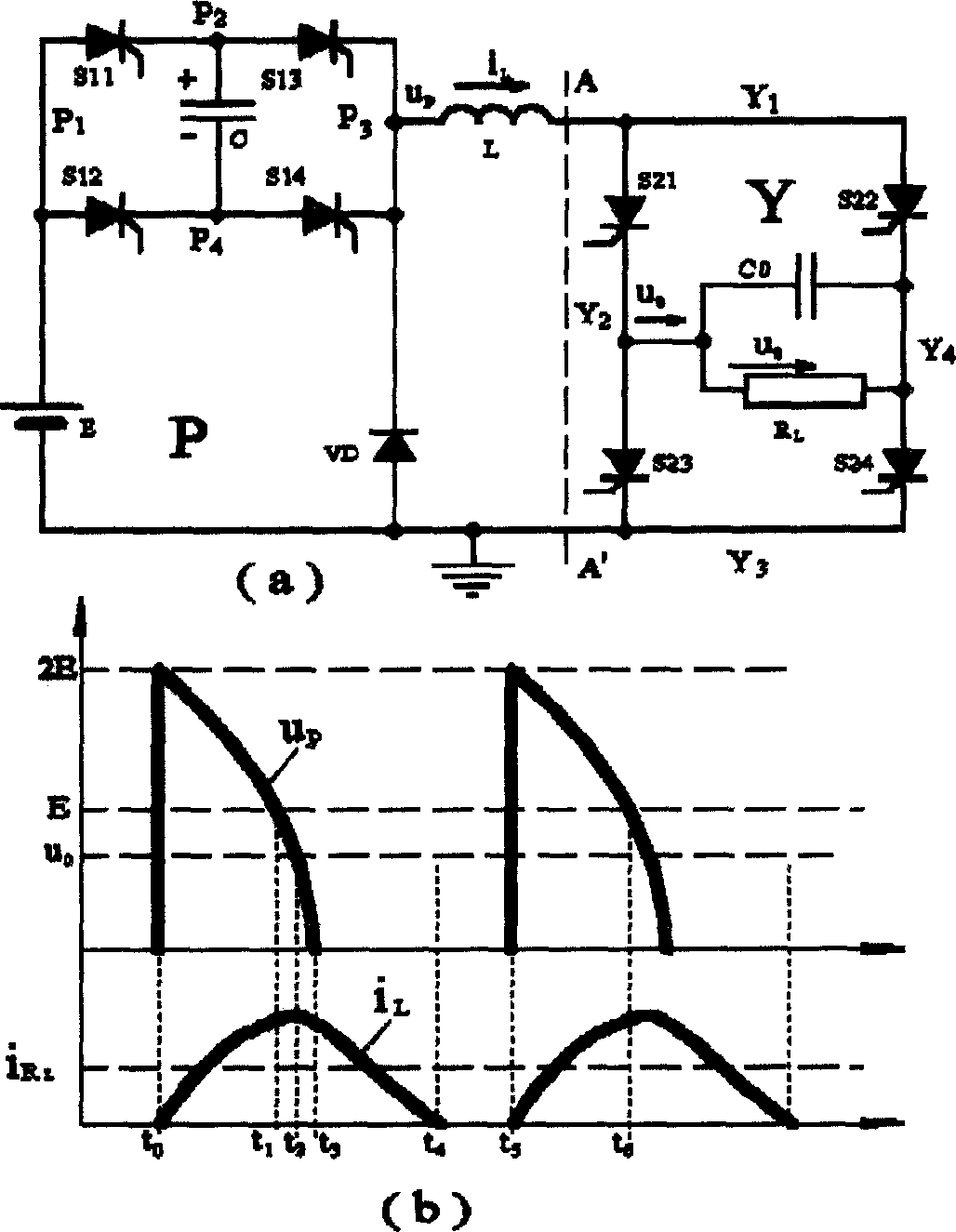

[0021] The power pulse forming circuit is divided into half-bridge asynchronous type and full-bridge synchronous type in structure. The half-bridge circuit only needs two switching elements and has a simple structure, but the transmission of each pulse energy needs to be divided into two steps to complete. , therefore, the chopping frequency and output power are relatively low; while the full bridge circuit requires four switching elements, but the transmission of each pulse energy can be completed in one step, therefore, the chopping frequency and output power are relatively high, The scope of application is also larger.

[0022] 1. The composition of the half-bridge asynchronous power pulse forming circuit

[0023] Circuit structure such as figure 1 As shown in the dotted line box in (a), the entire pulse forming circuit is composed of one-way thyristor S1, S2, resonant reactance L1, L2, resonant capacitor C an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com