Spiral algae rice wine and its brewing method

A technology for spirulina and rice wine, applied in the field of spirulina rice wine brewing and rice wine brewing, can solve problems such as poor taste, and achieve the effects of changing the astringent taste, eliminating the algal smell, and balancing nutrients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Take 105.5kg of rice with a polished rice rate of 60% (starch content > 85%), wash the rice with a machine until there is no cloudy liquid, soak it at a water temperature of 20°C for 12 hours; steam the rice under pressure for 10 minutes; then use neutral tap water Drain and cool the steamed rice to 35°C, add 50kg of spirulina powder (such as produced by Yunnan Green A Company) and mix evenly, and keep the temperature of the mixture at 30°C. During the fermentation process, the distiller’s mother is put in once, and the rice mixed with algae powder and the corresponding rice koji are added in three times, that is (the distiller’s mother is made of high-quality sake yeast, the amount of rice used is 8.5kg, and the rice koji can be used with Japan Association No. 13, and the amount of rice used is 26kg) Mix 8.5kg distiller's mother with 1 / 6 of rice and rice koji (17kg of rice, 4kg of rice koji and 11kg of algae powder) to ferment for 8 days at a fermentation temperature of...

Embodiment 2

[0014] Whole fermentation brewing process is identical with embodiment 1, and its difference is to use following batching to carry out:

[0015] The total amount of rice used is 140kg, the polished rice rate is 70%, 102kg of rice is used for steaming, 10kg of rice is used for distiller's mother, 28kg of rice is used for rice koji, and 47kg of spirulina powder is used. The alcohol volume in the final rice wine is 14%, the sugar content is 3.8%, and the acidity is 0.02%.

Embodiment 3

[0017] Whole fermentation brewing process is identical with embodiment 1, and its batching difference is as follows:

[0018] The total amount of rice used is 140kg, the polished rice rate is 65%, 99kg of rice is used for steaming, 11kg of rice is used for distiller's mother, 30kg of rice is used for rice koji, and 35kg of spirulina powder is used. The alcohol volume in the final rice wine is 15%, the sugar content is 4%, and the acidity is 0.03%.

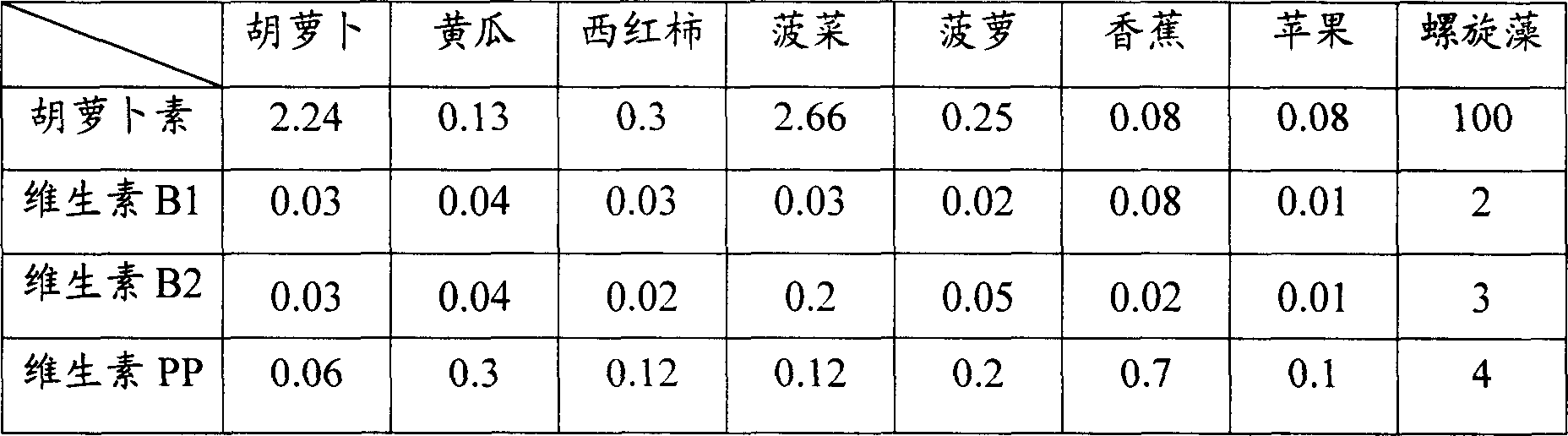

[0019] The drink of the present invention not only retains various nutritional components of spirulina, but also eliminates the algae smell of spirulina by using the characteristic of rice wine with a delicate fragrance and refreshing taste, and the combination of rice wine rich in various amino acids and vitamins and nutritional components of spirulina greatly improves the nutritional value of spirulina. The overall nutrient ratio of the drink makes it a real green drink with comfortable taste and rich nutrition.

[0020] It shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com