A kind of preparation method of chlorella drink

A production method and chlorella technology, applied in food science and other directions, can solve problems such as deficiencies, and achieve the effect of facilitating effective absorption and considerable market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

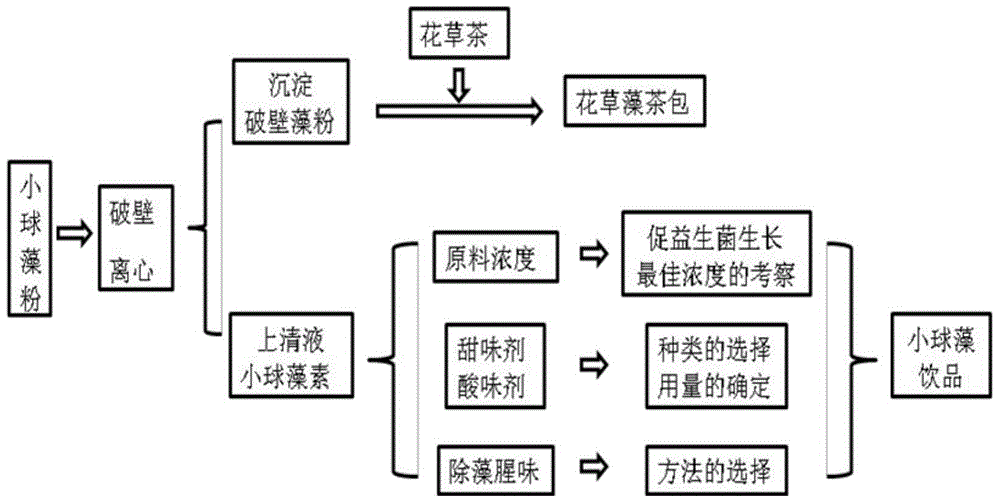

Method used

Image

Examples

Embodiment 1

[0032] (1) Chlorella algae powder pretreatment

[0033] Weigh the chlorella algae powder, add distilled water, and prepare a 5% algae liquid. After fully dissolving, turn on the constant temperature water bath and allow it to rehydrate in a water bath at 30°C for 3 hours to obtain the chlorella algae liquid.

[0034] (2) Ultrasonic method and chemical enzymatic method to break the wall

[0035] Take the chlorella liquid, put it into a beaker, cover the mouth of the cup with plastic wrap, and perform ultrasonic wall breaking, take crushed ice and add it around the beaker to prevent a large amount of heat from the ultrasonic process, use an ultrasonic pulverizer with an amplitude of 16 μm for 10 minutes, and Ultrasound for 5s, pause for 5s. After ultrasonically breaking the wall, add 0.4 million U of cellulase and 0.5 million U of pectinase per gram of algae powder for enzymatic breaking. The breaking process is carried out in a water bath at 37°C for 4 hours.

[0036] (3) Ext...

Embodiment 2

[0043] (1) Chlorella algae powder pretreatment

[0044] Weigh the chlorella algae powder, add distilled water, and prepare 8% algae liquid. After fully dissolving, turn on the constant temperature water bath, let it rehydrate in a 35°C water bath for 2.5 hours, and obtain the chlorella algae liquid.

[0045] (2) Ultrasonic method and chemical enzymatic method to break the wall

[0046] Take the chlorella liquid, put it into a beaker, cover the mouth of the cup with plastic wrap, and perform ultrasonic wall breaking, take crushed ice and add it around the beaker to prevent a large amount of heat from the ultrasonic process, use an ultrasonic pulverizer with an amplitude of 16 μm for 8 minutes, and Ultrasound for 5s, pause for 5s. After ultrasonically breaking the wall, add 0.3 million U of cellulase and 0.4 million U of pectinase per gram of algae powder for enzymatic breaking. The breaking process is carried out in a water bath at 35°C for 3 hours.

[0047] (3) Extraction of...

Embodiment 3

[0054] (1) Chlorella algae powder pretreatment

[0055] Weigh the algae powder, add distilled water, and prepare a 10% algae solution. After fully dissolving, turn on the constant temperature water bath, let it rehydrate in a water bath at 40°C for 2 hours, and obtain the chlorella algae solution.

[0056] (2) Ultrasonic method and chemical enzymatic method to break the wall

[0057] Take the chlorella liquid, put it into a beaker, cover the mouth of the cup with plastic wrap, and perform ultrasonic wall breaking, take crushed ice and add it around the beaker to prevent a large amount of heat from the ultrasonic process, use an ultrasonic pulverizer with an amplitude of 16 μm for 5 minutes, and Ultrasound for 5s, pause for 5s. After ultrasonically breaking the wall, add 0.4 million U of cellulase and 0.3 million U of pectinase per gram of algae powder for enzymatic breaking. The breaking process is carried out in a water bath at 37°C for 2 hours.

[0058] (3) Extraction of C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com