Hydraulic cavitate sterilizing apparatus

A sterilization device and hydraulic cavitation technology, applied in water supply devices, food science, food preservation, etc., can solve the problems of active ingredient destruction, thermal decomposition, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

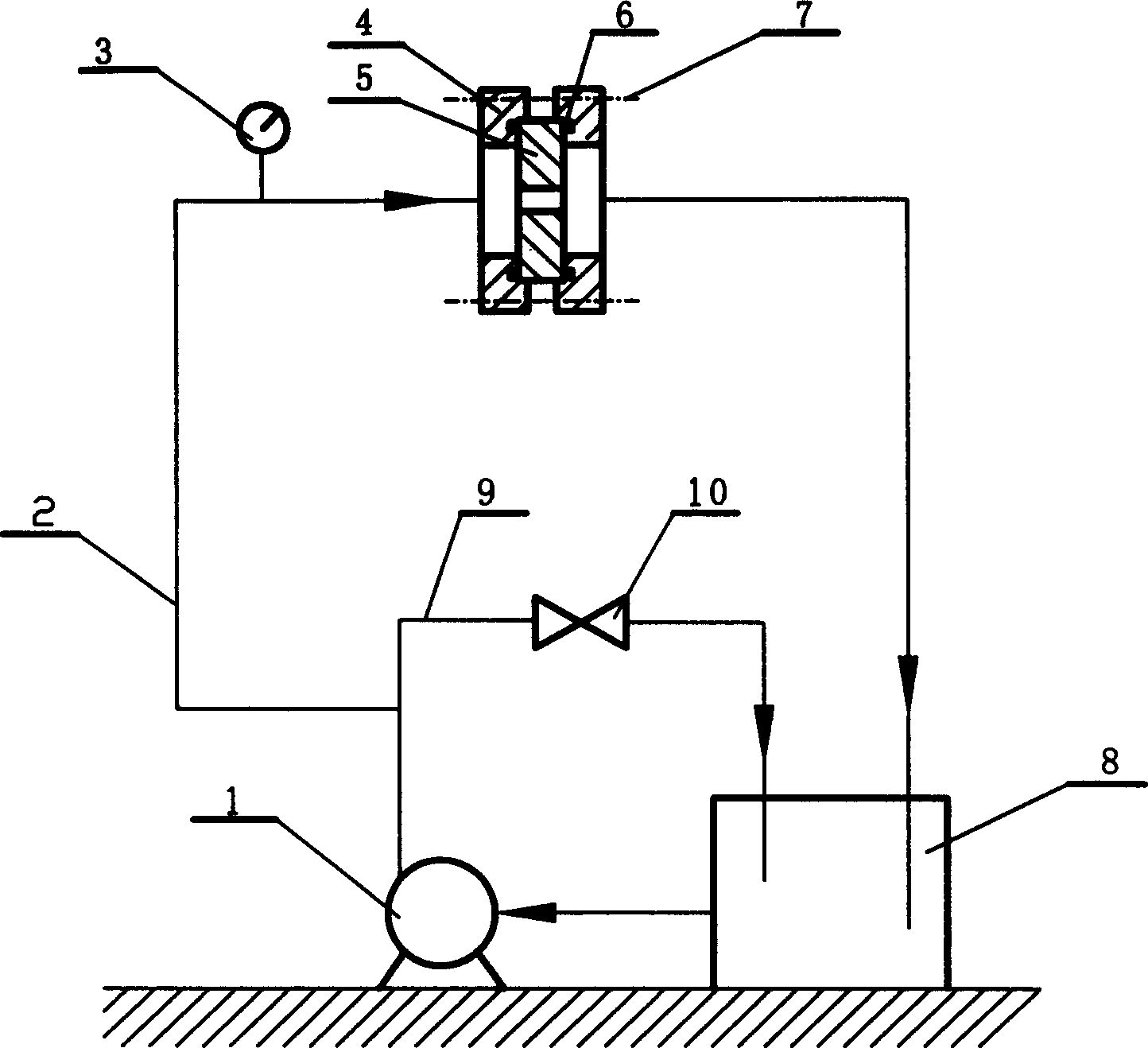

[0016] in the attached figure 1 Among them, a pump 1 is arranged at the outlet of the raw material tank 8, and the outlet of the pump 1 communicates with the main pipeline 2; the main pipeline 2 is equipped with an orifice plate 5, and the inlet of the orifice plate 5 communicates with the outlet of the pump 1, and the outlet of the orifice plate 5 communicates with the outlet of the pump 1. The raw material tank 8 is connected, and a pressure gauge 3 is installed at the entrance of the orifice plate 5; a bypass 9 is arranged at the outlet of the pump 1, and a valve 10 is installed on the bypass 9, and the inlet of the valve 10 is connected with the outlet of the pump 1, and the outlet of the valve 10 The outlet communicates with the raw material tank 8 .

[0017] The liquid raw material coming out of the raw material tank 8 is sent into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com