Lubrication-adding additive for internal combustion engine oil and its making method

A production method and additive technology, applied in the directions of additives, petroleum industry, lubricating compositions, etc., to achieve the effects of strong anti-wear, prolonging service life and enhancing lubricating function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

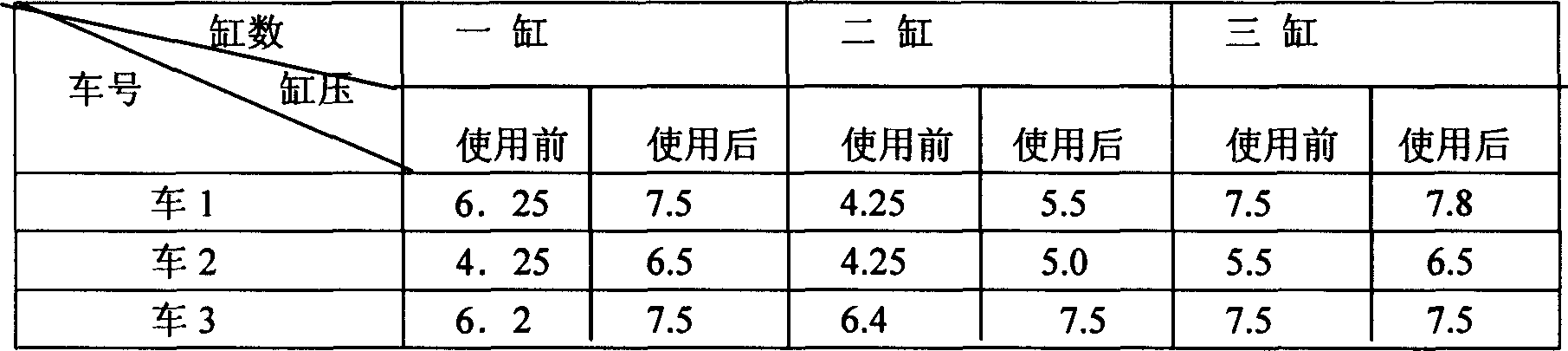

Image

Examples

Embodiment Construction

[0025] Get 45.6 parts by weight of molybdenum thiophosphate, 16.8 parts by weight of polyisobutene diimide, 16.4 parts by weight of phosphate ester amine salt, 21.2 parts by weight of SJ machine oil or CF machine oil, join 2 / 3 capacity in the blending kettle; The mixture is fully stirred and blended in the blending kettle at room temperature (electric stirring for 1 hour); the blending kettle is connected to the colloid mill, and the colloid mill is used for grinding and blending synchronously (1 hour) while stirring and blending to ensure that the particles are less than 10 Nano; heat the blending kettle with sealed steam at 90°C-100°C, use the hot pressure of the blending kettle itself to stand still for 2 hours, and then pack it into a finished product.

[0026] The use method of the present invention is to uniformly mix the present invention into the engine oil of an internal combustion engine at a ratio of 0.8% to 2.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com