Network electric welding machine control system and its control method

A network control system, welding machine technology, applied in transmission systems, network interconnection, arc welding equipment, etc., can solve problems such as large deviations in welding specifications, affecting welding quality, etc., to avoid human influence, improve efficiency, and achieve The effect of informatization and standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

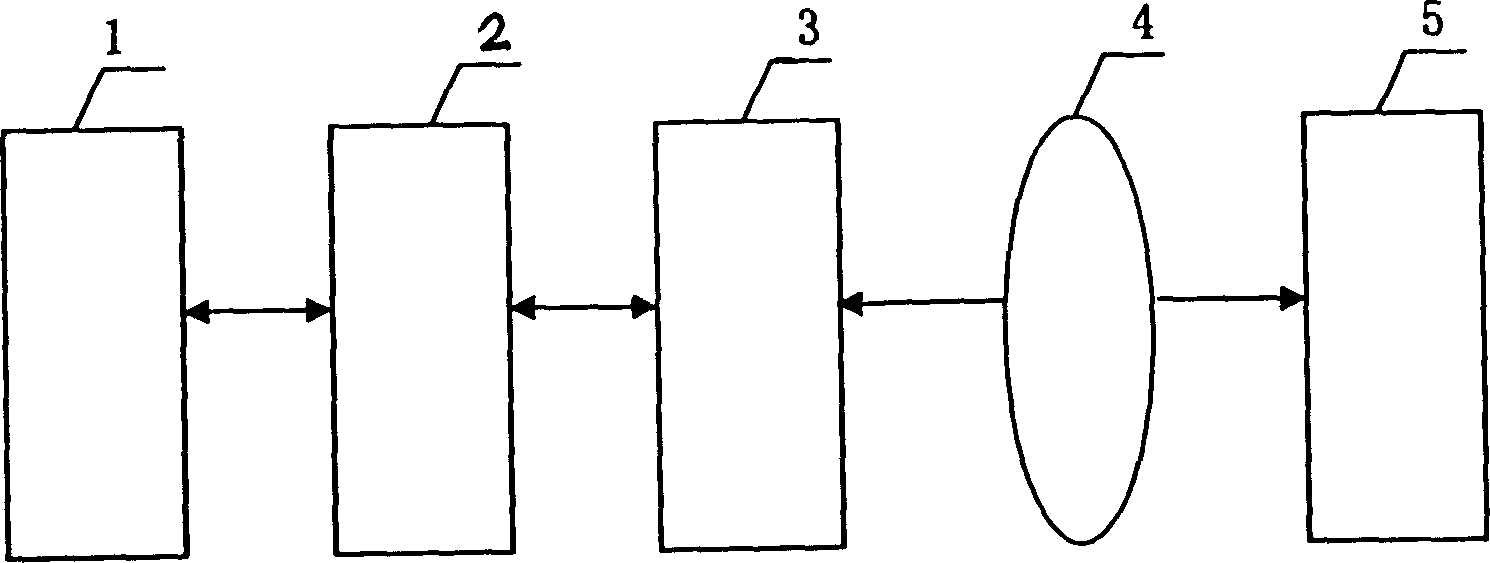

[0024] figure 1 It is a block diagram of the electric welding machine network control system of the present invention, which is composed of a network electric welding machine control unit (1), a network communication gateway (2), a field management computer (3), a public network (4), and a welding specification database server (5) composition. The control unit (1) is arranged in the cabinet of the electric welding machine, and the network communication gateway (2) is arranged in the cabinet of the electric welding machine, or arranged outside the cabinet of the electric welding machine. The control unit (1) is connected to the network communication gateway (2) through the communication interface (1-2), the network communication gateway (2) is connected to the on-site management computer (3), and the on-site management computer (3) is connected to the The welding code database server (5) is connected.

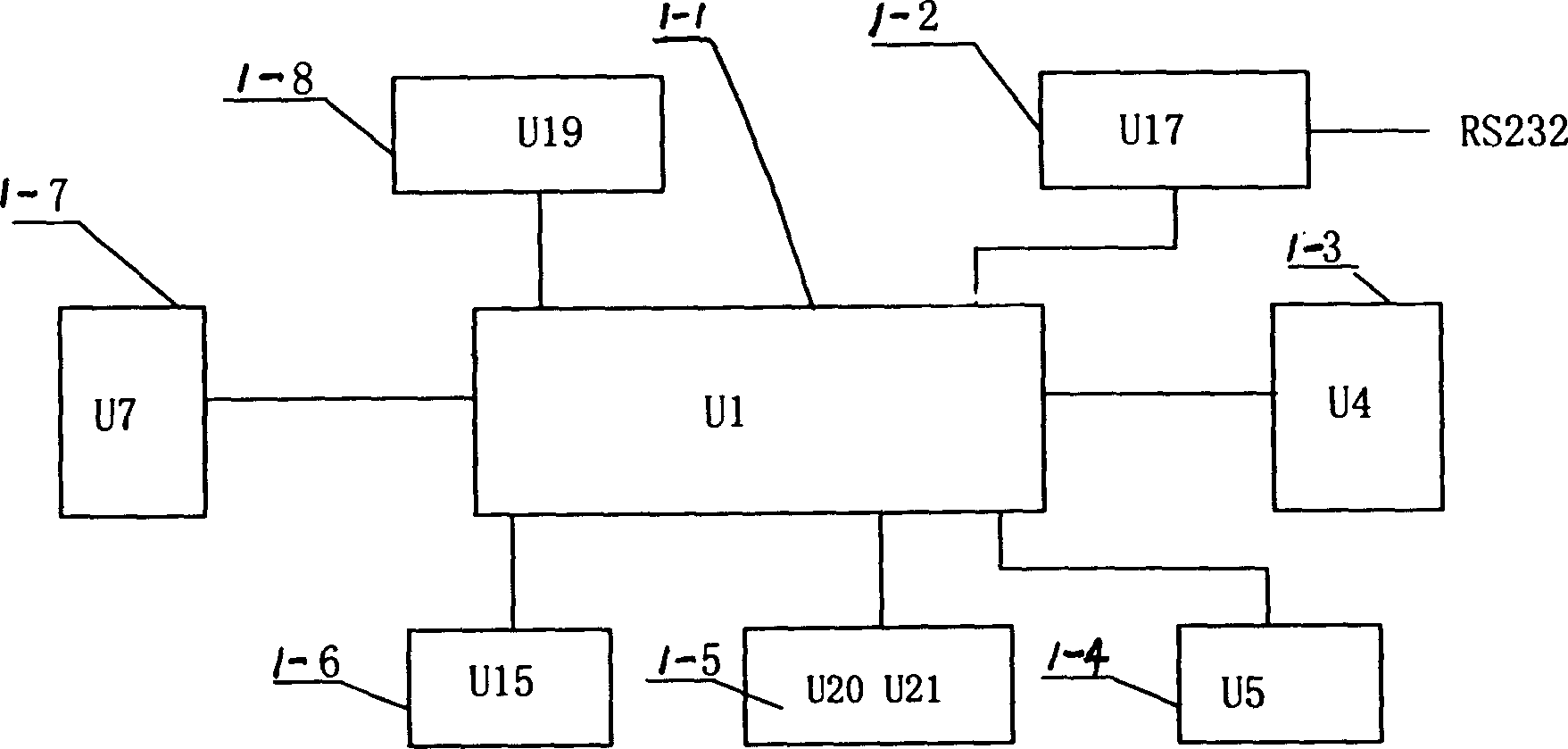

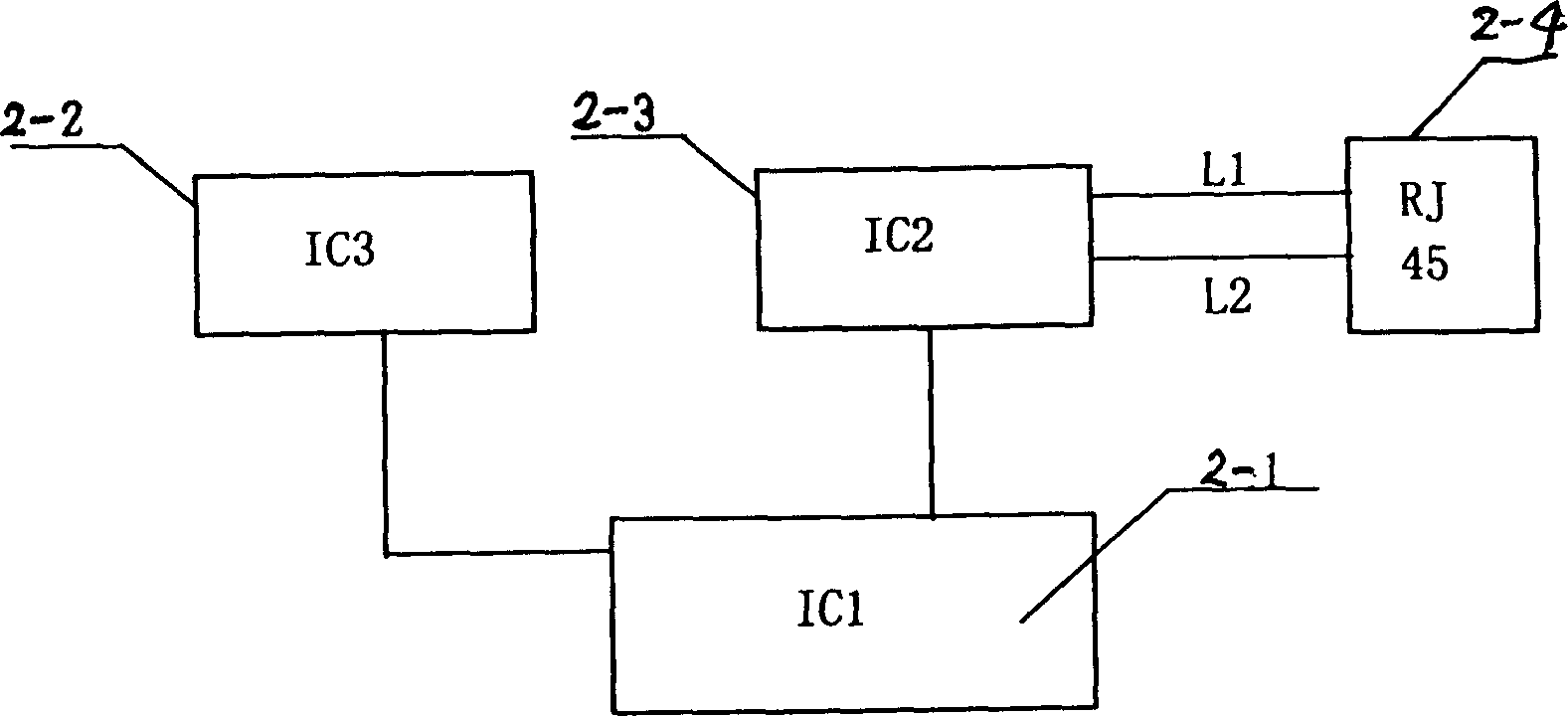

[0025] like figure 2 As shown, the network welding machine control unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com