Hetero-composite yarn, fabrics thereof and methods of making

A yarn, heterogeneous technology, applied in the field of heterogeneous composite textile yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] Methods of making the above polymers are known in the art and may include the use of catalysts, cocatalysts and chain branching agents known in the art.

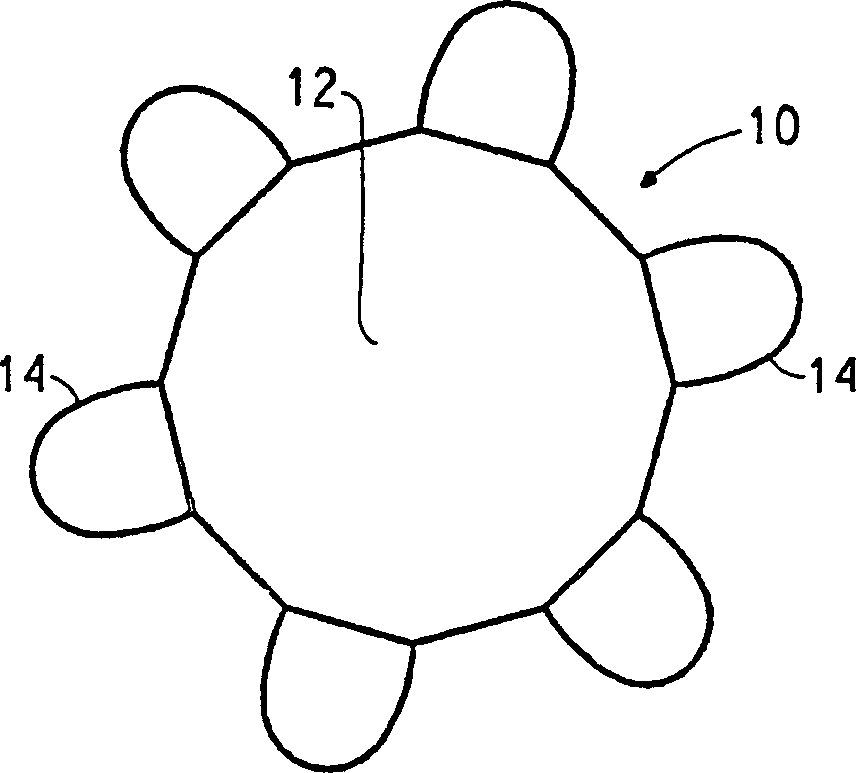

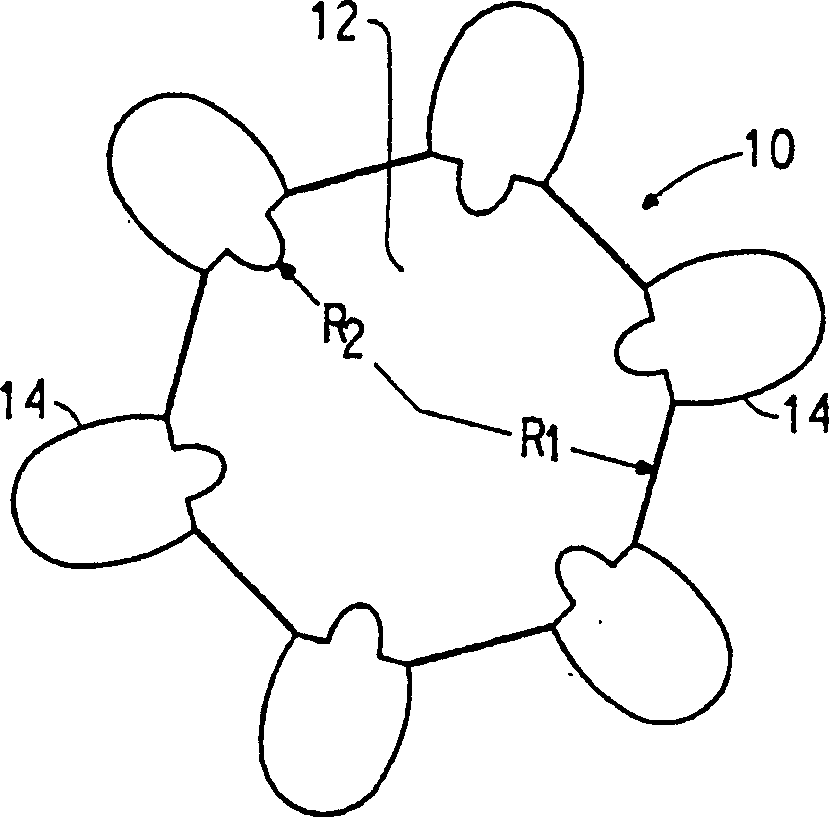

[0061] The high elasticity of the core enables it to absorb compressive and tensile forces as the fibers are stretched and relaxed as the core is twisted by the wings to which it is attached. These forces can cause the two polymers to detach if their attachment is too weak. The present invention optionally uses a mechanical lock of the wing and core polymers to enhance this attachment and further minimize detachment during fiber processing and use. The bond between the core and wings can be further strengthened by choice of wing and core composition and / or use of adhesion-promoting additives to either or both of these polymers. Adhesion promoters can be used in each of these wings or in only some of them. Thus, individual wings can be laminated to the core to varying degrees, for example, some wings can be intention...

Embodiment 1

[0126] Air-entangled bicomponent composite yarns in knitted fabrics

[0127] An air-entangled heterogeneous composite-yarn with potential stretch and recovery properties was prepared by air-entanglement of a first monofilament bicomponent yarn of the present invention and a second commercially available partner yarn.

[0128] Bicomponent Yarn Spinning

[0129] the bicomponent yarn along the Figure 10 Route C was spun to produce filaments of 19 denier (21 dtex) per filament. Other fiber and spinning properties are as follows:

[0130] denier 19

[0131] #filament 1

[0132] Wing / Core Interfitting Yes

[0133] Feeding roller speed (m / min) 420

[0134] Initial Trim None

[0135] Initial trim % 0

[0136] Second Trim Type K-9349

[0137] Second trimming % 4%

[0138] Wing polymer Camacari N6 DuPont Brazil SA

[0139] Additives in Wing Polymer 5% Nylon 12 Rilson AMNA Atofina

[0140] Wing Volume % 40

[0141] Number of wings 5

[0142] Core polymer Pebax 3533SN (...

Embodiment 2

[0173] Air-jet texturized bicomponent composite yarns for knitting applications

[0174] The heterogeneous yarns according to the invention are prepared by air jet texturing a feed yarn consisting entirely (2.a.) or partly (2.b.) of bicomponent fibers with fancy yarns without bicomponent fibers. - Composite-yarn combination.

[0175] raw material

[0176] The polymer starting material was the same as shown in Example 1. In Example 2.a. a feed yarn consisting of 10 filament bicomponent yarns of 70 denier was spun as follows.

[0177] In Example 2.b., the feed yarn consisted of simultaneously fed 30 denier monofilament bicomponent and 70 denier 66 filament nylon Tactel * Industrial yarns (sold by E.I. DuPont deNemours and Co., Wilmington, Delaware) were assembled. The properties of the 30 denier bicomponent monofilament are shown below.

[0178] The decor thread used in Examples 2.a. and 2.b. was also 66 filament DuPont Tactel of 70 denier * .

[0179] Bicomponent Y...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| stretch ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com