Porous restrictor for gas bearing

A fluid bearing and porous body technology, which is applied in the field of current limiting devices, can solve problems such as high cost and blockage of small particles, and achieve the effects of reducing labor costs and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

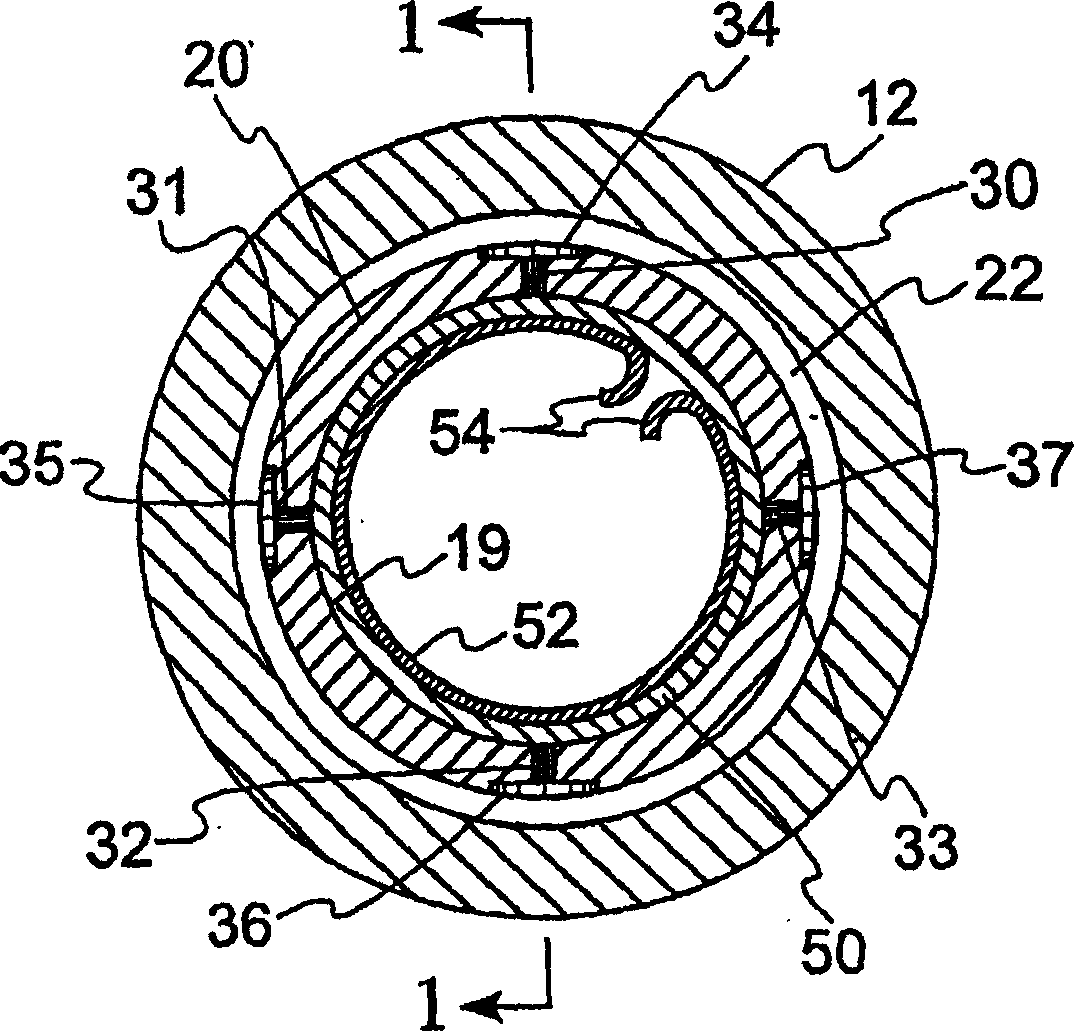

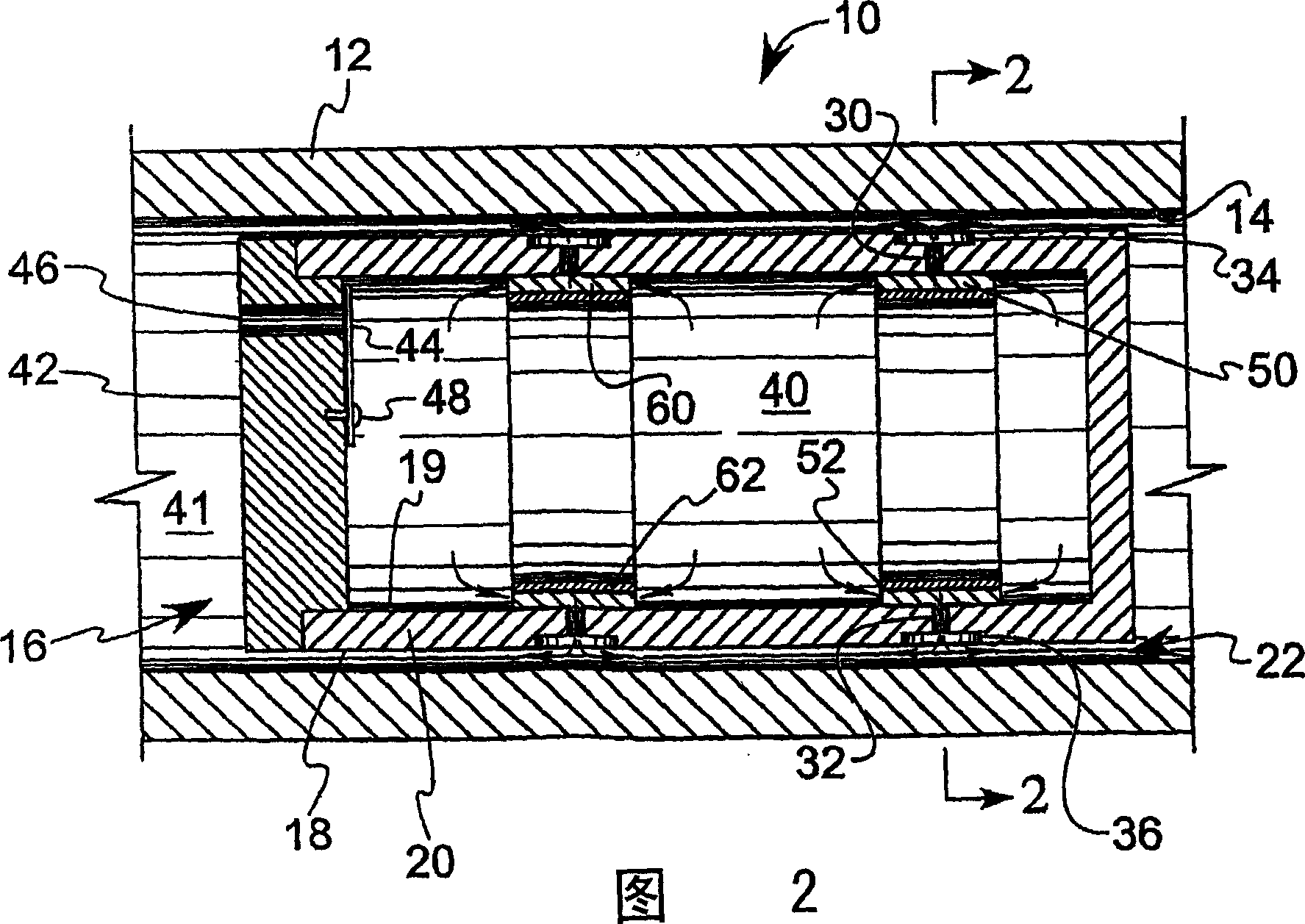

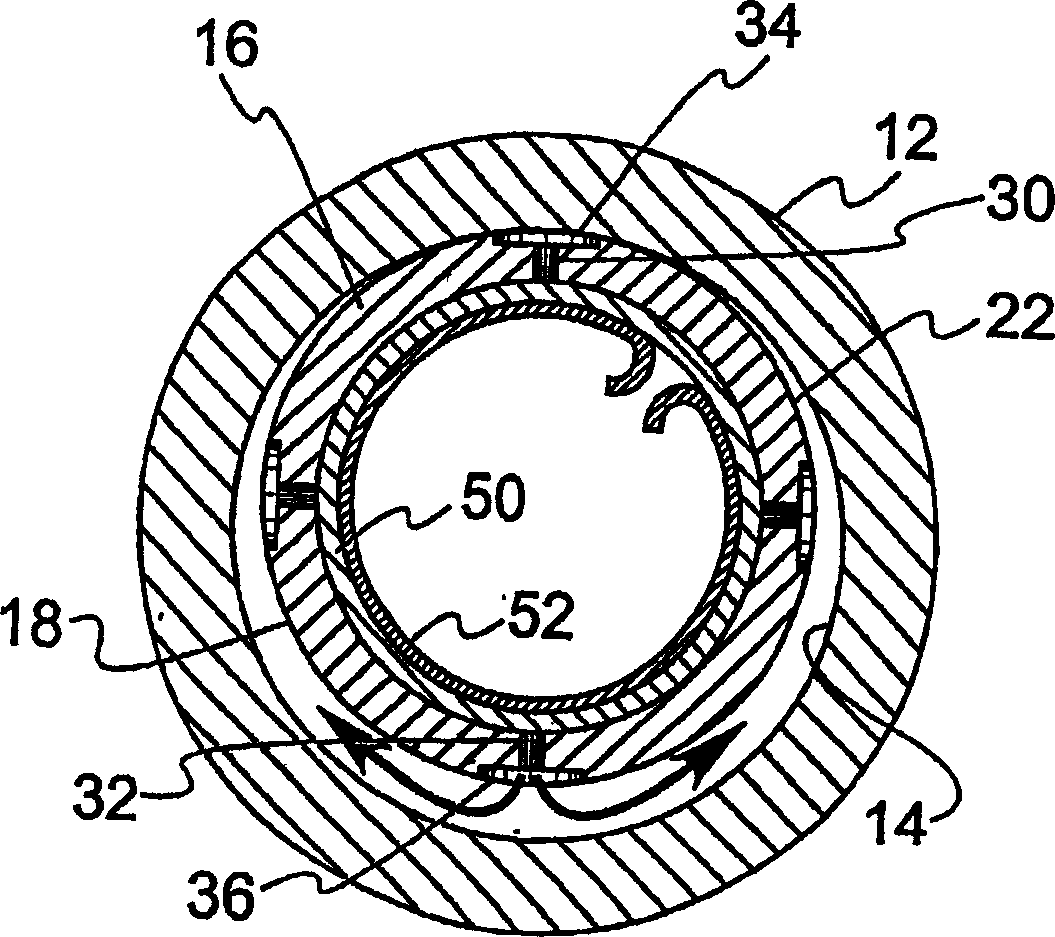

[0021] figure 1 Shown is a preferred embodiment of the invention wherein a free piston Stirling cycle device 10 includes a cylindrical housing 12 with an inner side wall surface 14 . Figure 4 The piston 16 shown has an outer cylindrical surface 18 on the side wall 20 which abuts the inner cylindrical surface 14 of the housing side wall 12 .

[0022] An annular gap 22 is formed between the piston 16 and the housing 12 into which a working fluid such as helium flows. The dimensions of the annulus have been exaggerated in the figures. In the contemplated embodiment, the diameter difference between the outer surface of the piston 16 and the inner surface 14 of the housing is about 15 to 35 microns. Therefore, when the piston 16 is at radial dead center (zero eccentricity), the annular gap is half of this difference in diameter, ie equal to 7.5 to 17.5 microns. Gas flows through the annulus 22, resulting in what is commonly known as a hydrodynamic bearing.

[0023] The gas ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com