Tank furnace for producing basalt fibers continuously

A technology of basalt fiber and pool kiln, which is applied in the direction of furnace type, glass manufacturing equipment, furnace, etc., can solve the problem of low melting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

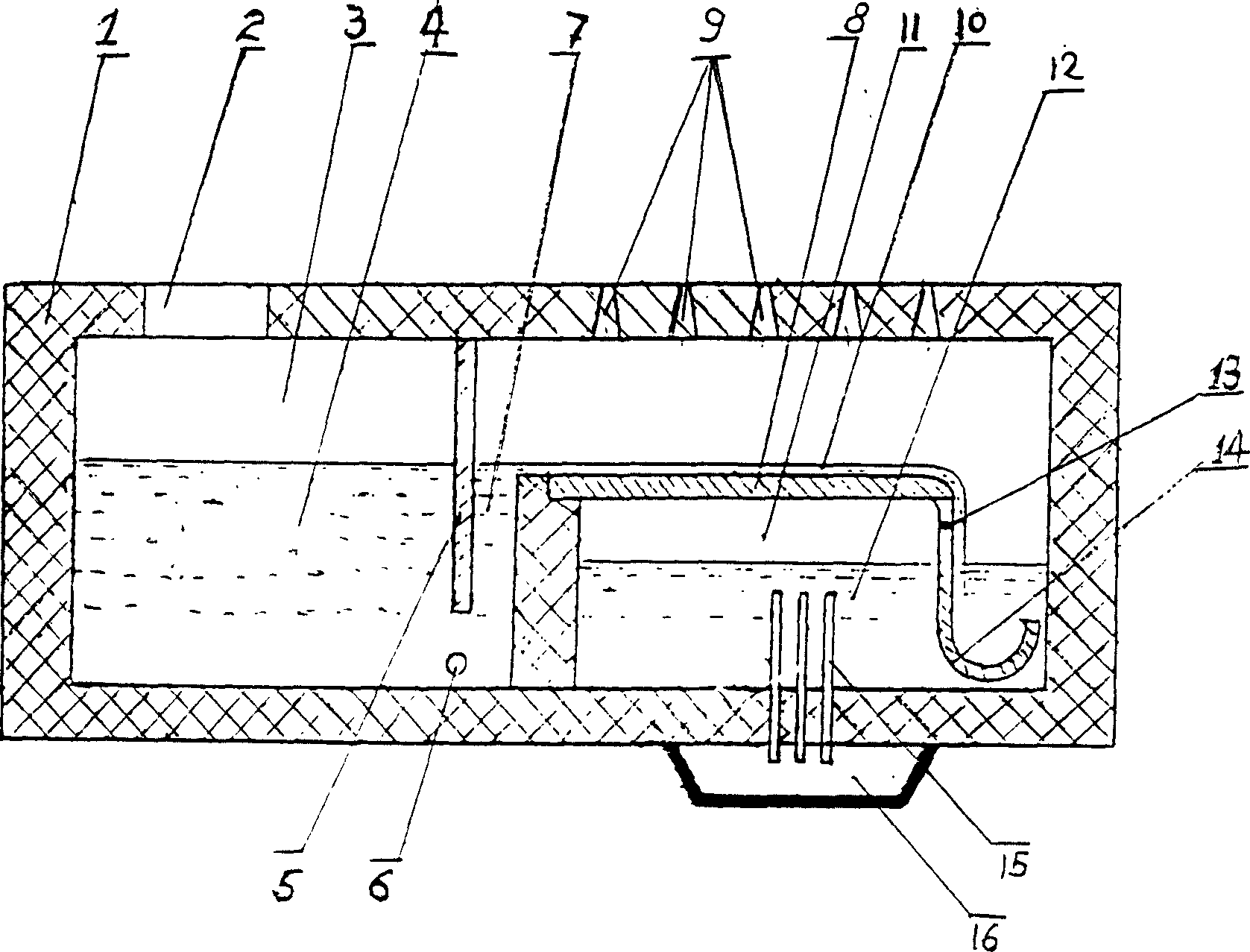

[0014] Raw materials are fed into the kiln through the feeding port (2) and melted in the melting tank (3). Its heating method can be electric plate or fuel burner. Between the melting pool (3) and the working area, a partition wall (5) is provided to completely separate the spaces of the two parts. Under the partition wall (5), a flow hole (6) is established, and the melting body that has been melted in the melting pool (3) enters the vertical ascending channel (7) of the work area through the flow hole (6), and the passage (7 ) is lower than the liquid level of the melt. The melt is degassed and homogenized during its ascent. Thereafter, the melt forms a thin overflow strip (10) on top of the heat shield (8). During the forward process, further degassing and homogenization.

[0015] The degassed and homogenized melt flows down the skirt plate (13) into the melt pool (12) in the working area. A semi-cylindrical chute (14) is provided below the skirt plate (13), the purpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com