Technique for preparing tea wine

A production process and tea wine technology, which is applied in the preparation of alcoholic beverages and other directions, can solve problems such as the destruction of nutrients, and achieve the effect of good taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

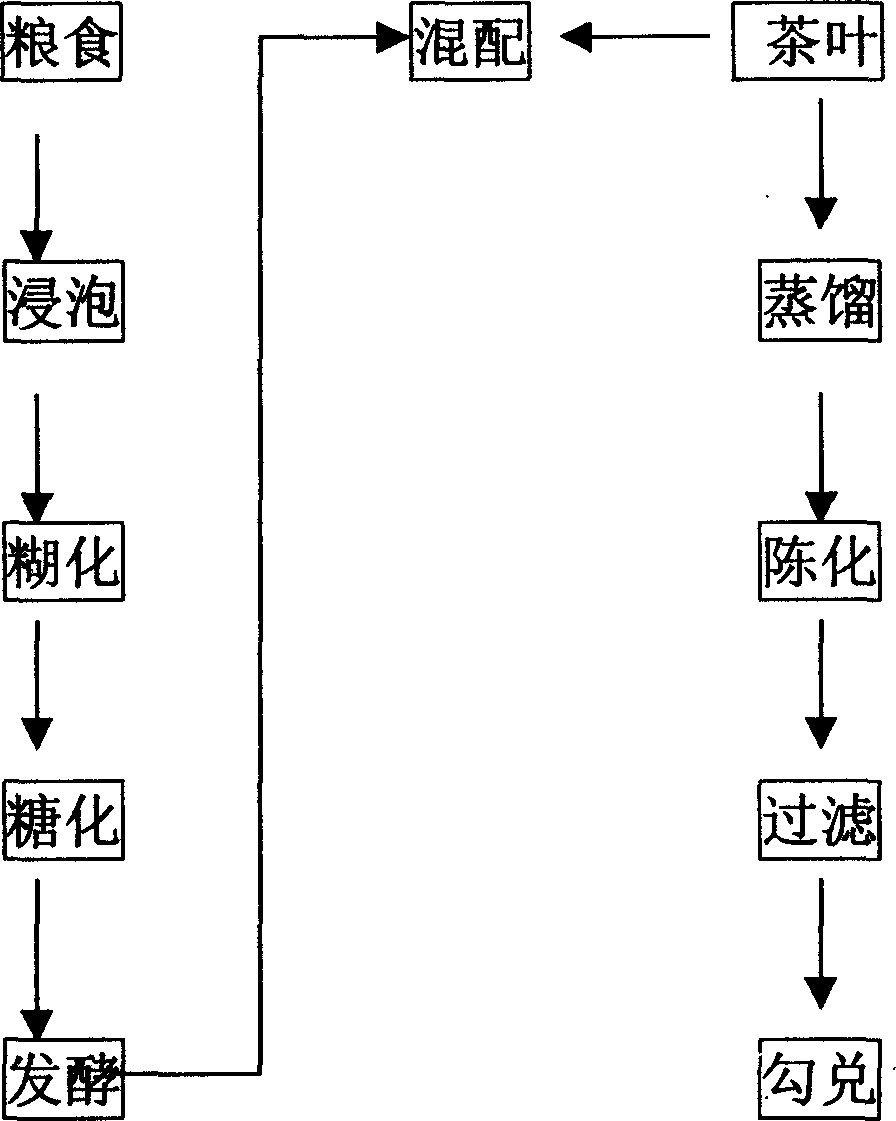

[0005] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: The present invention will be further described below in conjunction with the accompanying drawings.

[0006] 1. Raw material processing

[0007] 1. Grain processing: Choose high-quality sorghum, red rice, wheat or corn, wash the pure grain with clean water, and soak for 12 to 24 hours to improve the quality of the wine.

[0008] Gelatinization: Take out the washed pure grains, place them for 10-30 minutes, drain the surface water, then place them in a retort for steaming and gelatinization for 5-6 hours, and steam them until they are cooked.

[0009] Saccharification: Take the steamed wine sheet out of the retort quickly, spread it to cool down to below 18-22 degrees, and then spread the wine koji at a ratio of 4 / 1000. You can mix and sprinkle the wine koji multiple times, and strive to achieve the best uniformity. Put it into the saccharification box for saccharification, and do a good job in the surrounding sacchari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com