Method of self-calibrating of current ratio standard device

A technology of current ratio and standard device, which is applied in the direction of measuring device, measuring electric variable, instrument, etc., to achieve the effect of simple structure, convenient use and fast calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] A method for self-calibration of a current ratio standard device, the current ratio standard device includes 4 sets (minimum 3 sets, generally 3-5 sets, which makes it more convenient to use when the current is expanded, and the difficulty of manufacturing a comparator is reduced) self-balancing current The comparator, through the steps of self-calibration, addition, β measurement, comparison, and multiplication, completes the absolute calibration of the current ratio, and obtains the current ratio error of each current comparator.

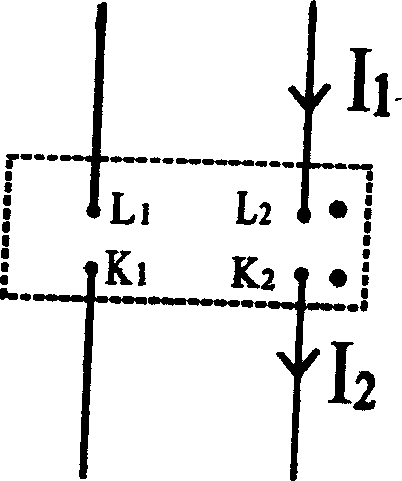

[0077] A schematic diagram of a self-balancing current comparator is available figure 1 express. L1 L2: primary winding; K1 K2: secondary winding. L1, L2 are electrically isolated from K1, K2.

[0078] L2 and K2 are terminals with the same name, that is, if the primary current I1 enters from L2, the secondary current I2 exits from K2.

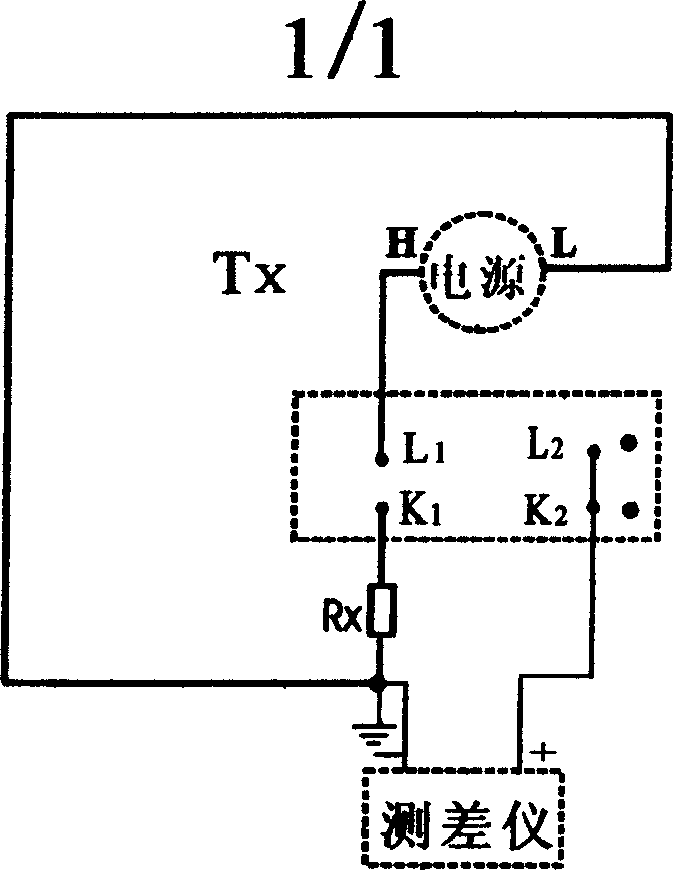

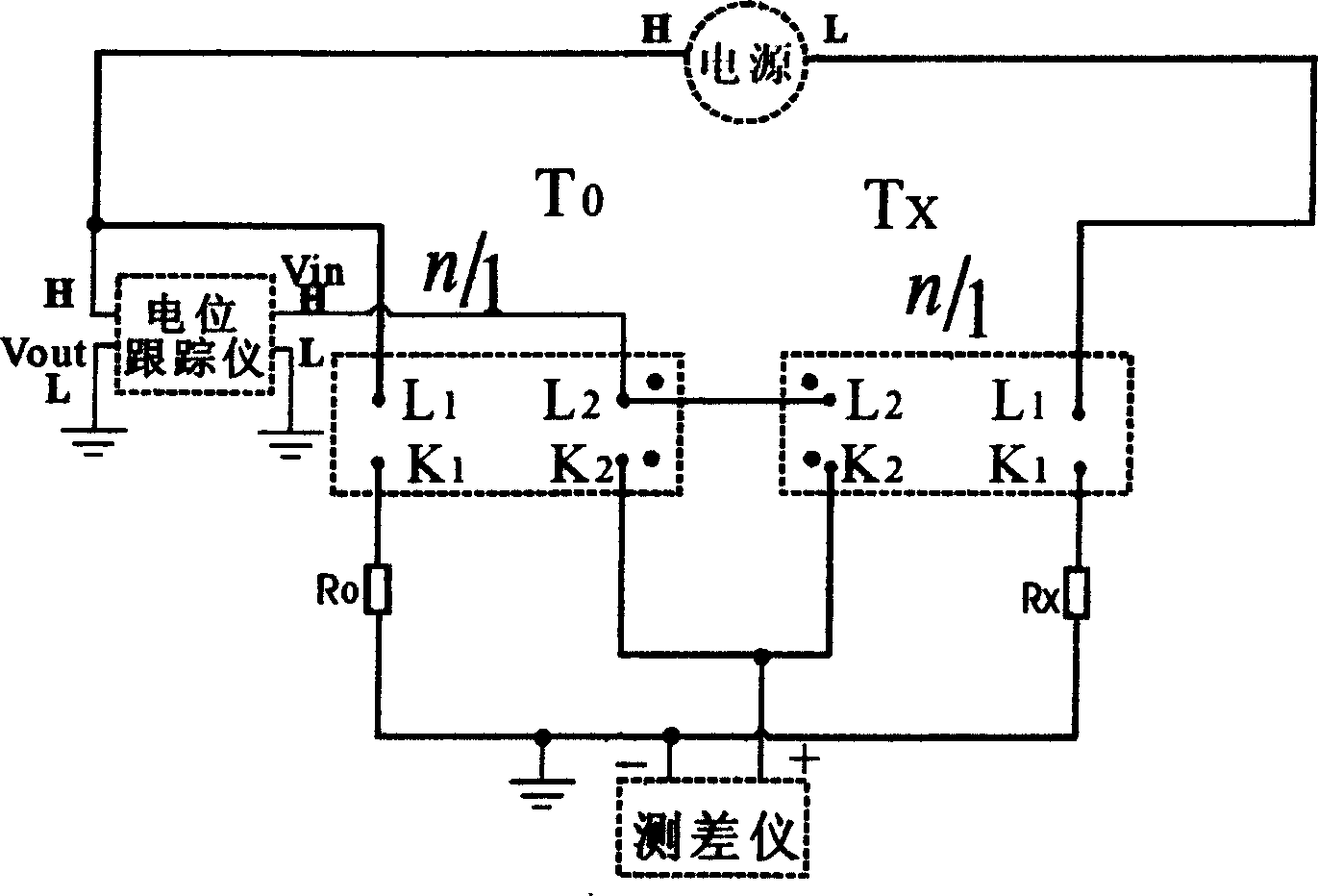

[0079] The specific calibration circuit is as follows:

[0080] 1. DC current comparator self-calibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com