Soft-base solid pigment sensitive film solar cell and its prepn. method

A solar cell and dye sensitization technology, applied in the field of solar cells, achieves the effects of stable performance, simple manufacturing process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

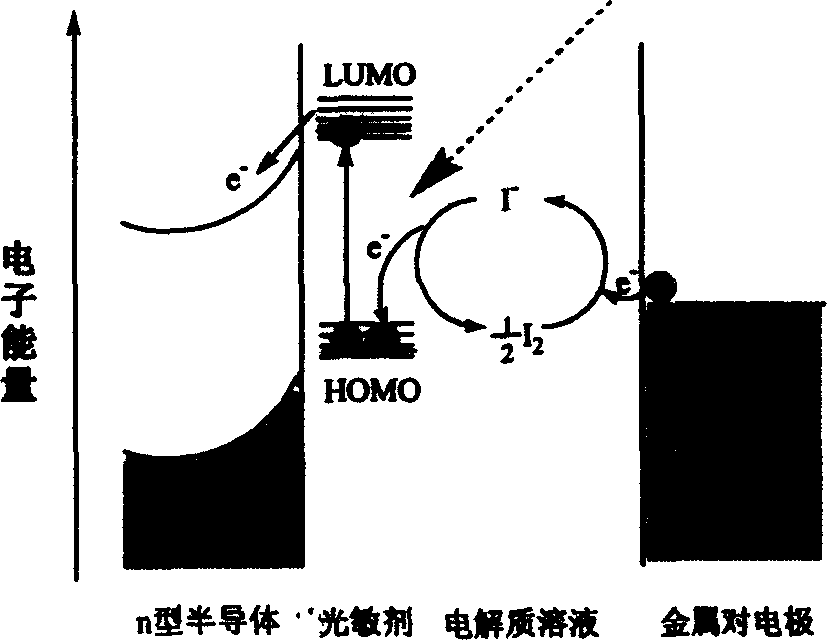

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

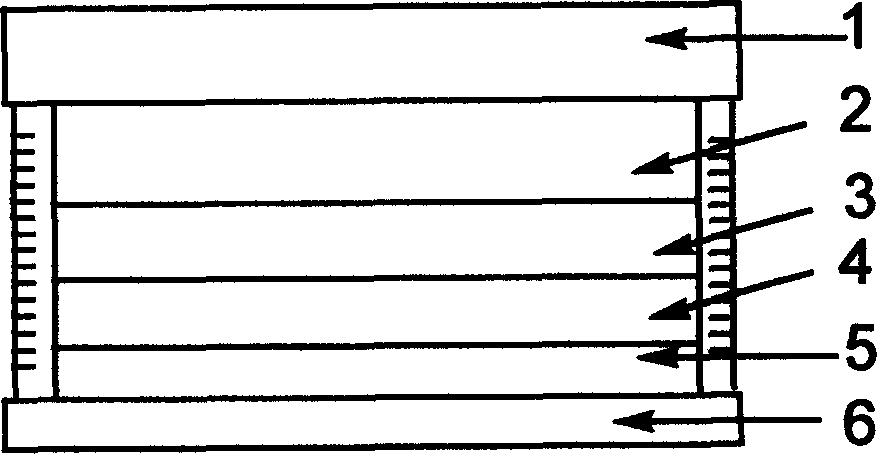

[0051] The structure of the soft-base solid-state dye-sensitized thin-film solar cell of the present invention is a layered structure, that is, TiO is provided under the light-transmitting conductive polyester sheet 1. 2 Nanocrystalline film 2, on TiO 2 Nanocrystalline film 2 is provided with LnPc 2 Sensitized layer 3, in LnPc 2 A solid electrolyte layer 4 is arranged under the sensitizing layer 3 , a soft metal film back electrode 5 is arranged under the solid electrolyte layer 4 , and a high barrier composite AL film 6 is arranged under the soft metal film back electrode 5 .

[0052] The method that the present invention makes is:

[0053] a. Choose a flexible polyester film as the electrode material substrate, the thickness of the substrate is 0.1mm-0.2mm, the visible light transmittance is 70-80%, and the surface sheet resistance is 14Ω / □,

[0054] b. Coating TiO on the surface of the flexible substrate material 2 slurry,

[0055] c. The slurry should be spread evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com