Method for repairing defects of electrode pattern

An electrode pattern and defect technology, applied in the field of repairing defects, can solve problems such as poor electrode discharge effect, deterioration of plasma display display effect, and scrapping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

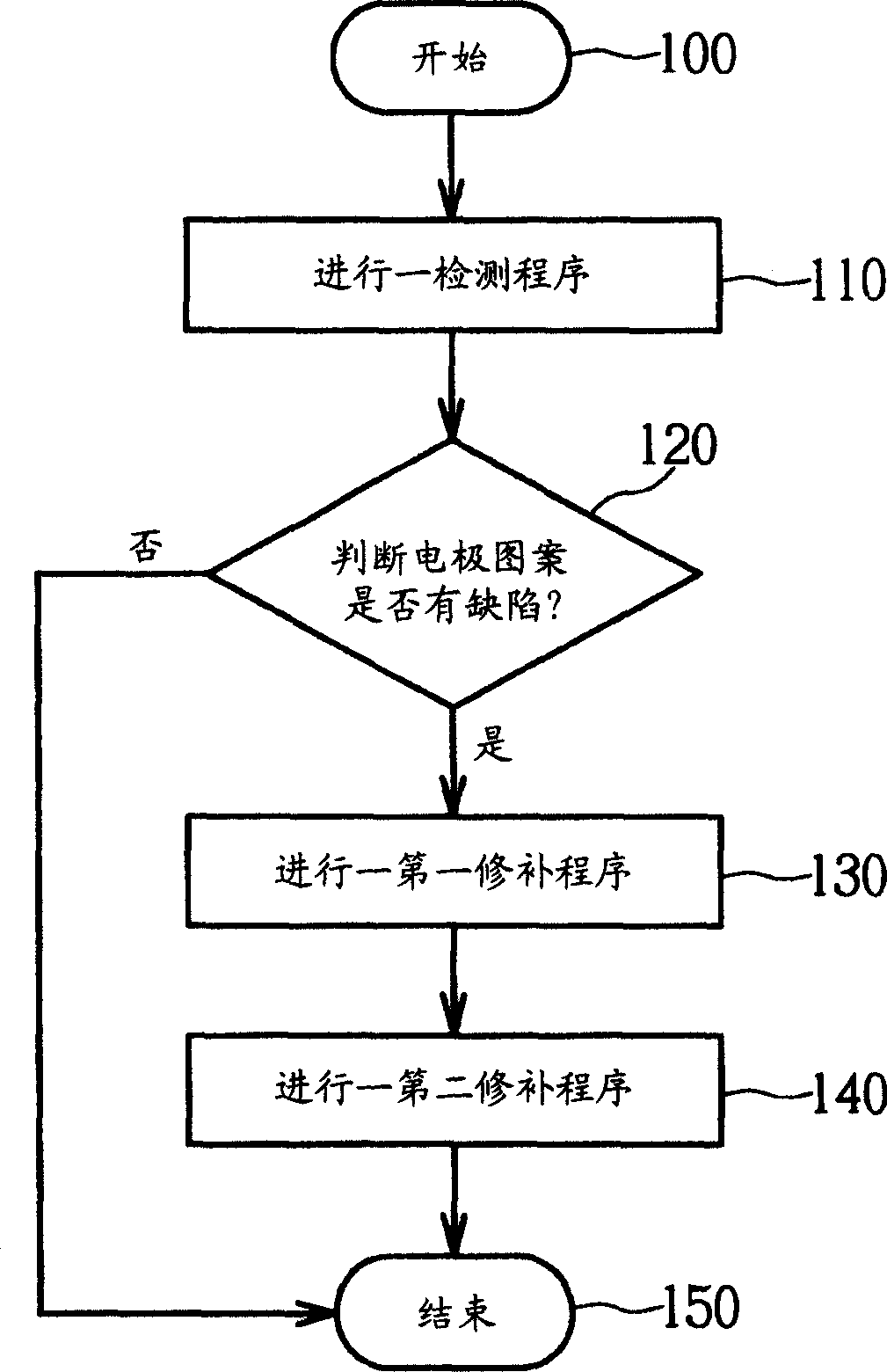

[0027] Please refer to figure 1 , figure 1 It is a flowchart of the method for repairing electrode pattern defects of the present invention. Such as figure 1 As shown, the method for repairing electrode pattern defects of the present invention includes the following steps:

[0028] Step 100: Start;

[0029] Step 110: Perform a detection procedure to detect the electrode pattern of the plasma display;

[0030] Step 120: Determine whether the electrode pattern is defective, repair it if there is a defect, and end the repair process if there is no defect;

[0031] Step 130: Perform a first repair procedure to fill the recessed part of the electrode pattern;

[0032] Step 140: Perform a second repair procedure to remove the protruding part of the electrode pattern; and

[0033] Step 150: End.

[0034] As mentioned above, the method for repairing electrode pattern defects of the present invention is to perform a detection procedure after the production of the plasma display electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com