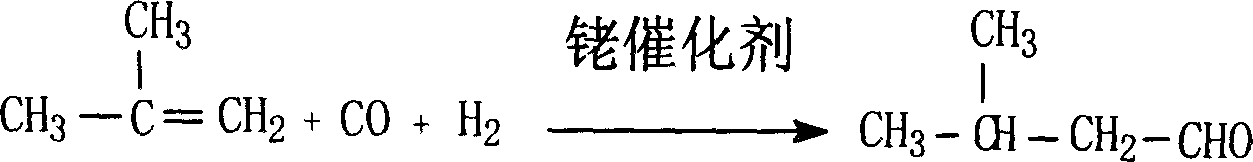

Process for making isopentyl aldehyde from isobutene

A technology for isobutene and isovaleraldehyde, applied in the field of preparing isovaleraldehyde, can solve the problems of high production cost, large environmental pollution, less sources and the like, and achieves the effects of low production cost, less environmental pollution and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] In a 100ml reactor, add 10.24mmol of rhodium catalyst, after fully replaced by inert gas, add 11.8g (210mmol) of isobutene, and feed CO, H with a volume ratio of 1:1. 2 After the gas mixture, the pressure was increased to 5Mpa, the temperature was raised, and the reaction was started. After 2 hours of reaction, the temperature was lowered to stop the reaction, and 17.5 grams of the product were obtained. The product was analyzed by gas chromatography, and the content was 98.5%.

Embodiment 2

[0013] In a 100ml reactor, add 8.33mmol of rhodium catalyst, after fully replaced by inert gas, add 11.8g (210mmol) of isobutene, and feed CO, H with a volume ratio of 1:1. 2 After mixing the gas, the pressure was raised to 8Mpa, the temperature was raised, and the reaction was started. After 3 hours of reaction, the temperature was lowered to stop the reaction, and 17.3 grams of the product were obtained. The product was analyzed by gas chromatography, and the content was 98.2%.

Embodiment 3

[0015] In a 100ml reactor, add 7.00mmol of rhodium catalyst, after fully replaced by inert gas, add 11.8g (210mmol) of isobutene, and pass through CO, H with a volume ratio of 1:1. 2 After mixing the gas, the pressure was raised to 10Mpa, the temperature was raised, and the reaction was started. After 4 hours of reaction, the temperature was lowered to stop the reaction, and 17.1 grams of the product were obtained. The product was analyzed by gas chromatography, and the content was 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com