Collagen purification method using CO2 supercritical fluidization method

A technology of supercritical fluid and collagen, which is applied in the preparation of animal glue or gelatin, the production of bulk chemicals, and the extraction of solvents from liquid solutions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

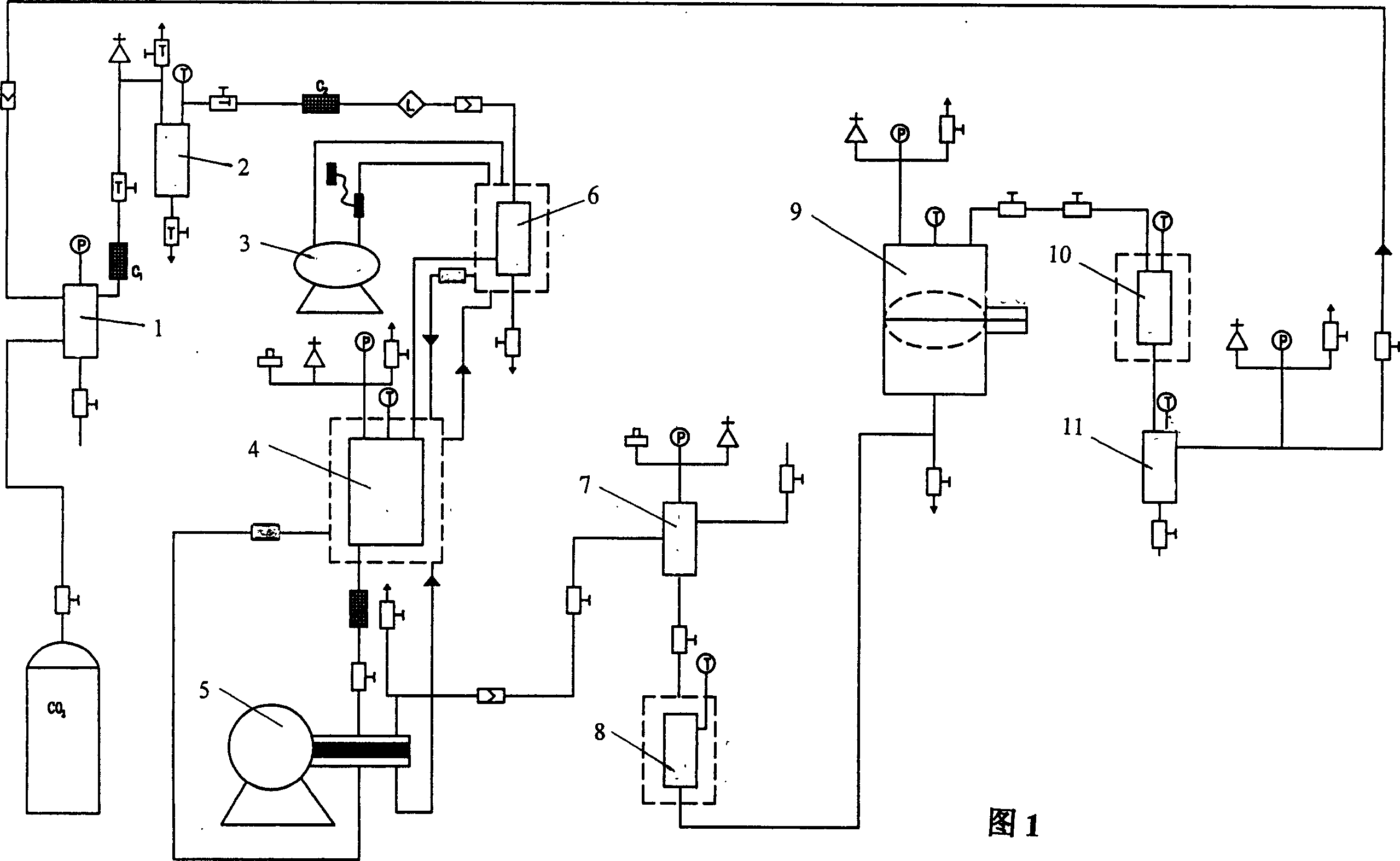

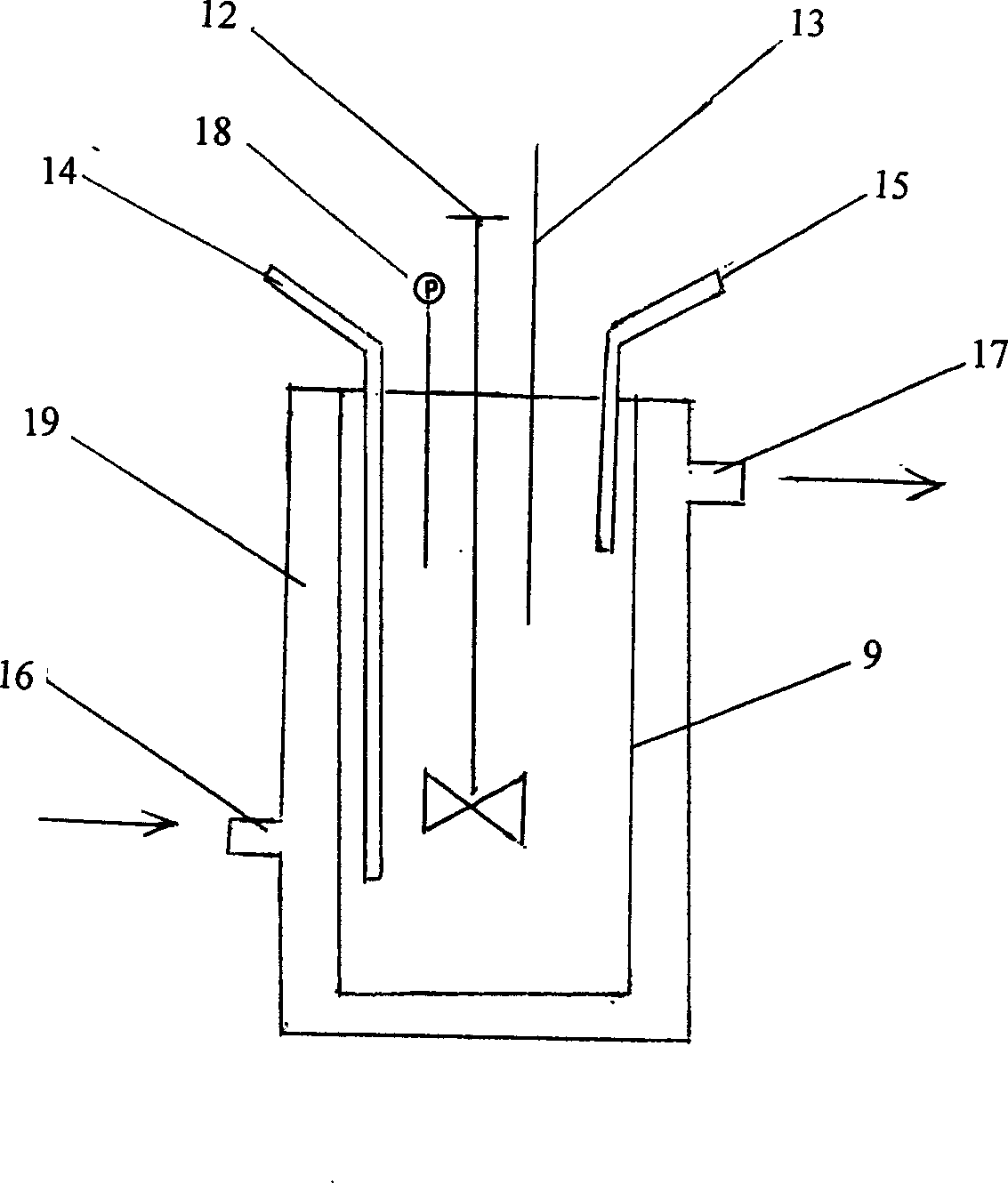

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: 1000g of purified pigskin collagen

[0036] Reaction conditions: Temperature: 40°C Pressure: 16MPa

[0037] Time: 60min Speed: 55 rpm

Embodiment 2

[0038] Embodiment 2: 1000g of purified sheepskin collagen

[0039] Reaction conditions: Temperature: 36°C Pressure: 14MPa

[0040] Time: 80min Speed: 40 rpm

Embodiment 3

[0041] Embodiment 3: 1000g of purified bovine tendon collagen

[0042] Reaction conditions: Temperature: 45°C Pressure: 18MPa

[0043] Time: 90min Speed: 50 rpm

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com