Wooden staircase of modular construction

An assembled and stair technology, applied in the direction of stairs, treads and vertical plate units, etc., can solve the problems of increasing the cost of stair production, increasing the time of rework, and damage to the stair board surface, achieving the best assembly effect and improving assembly work efficiency. , the effect of high ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

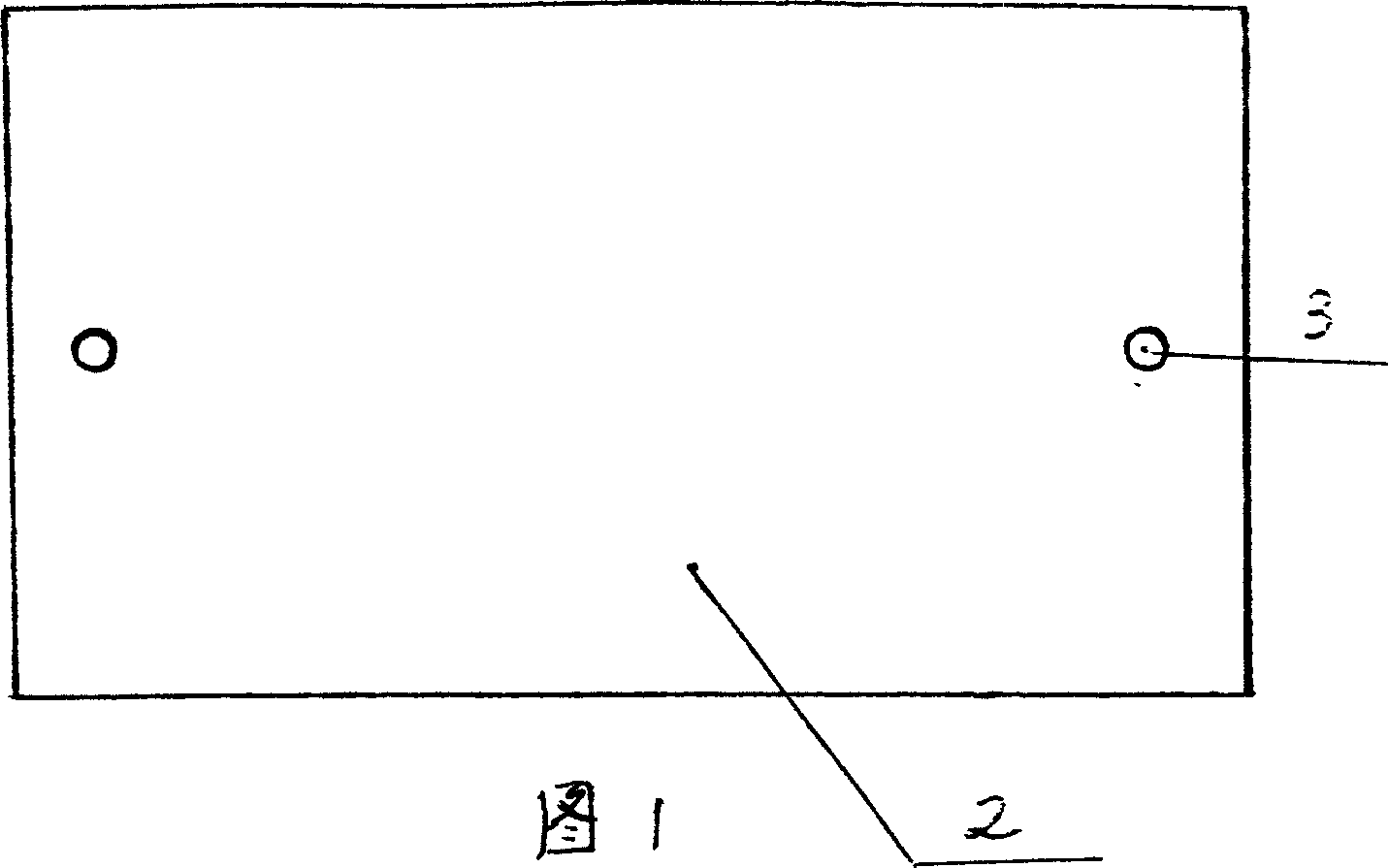

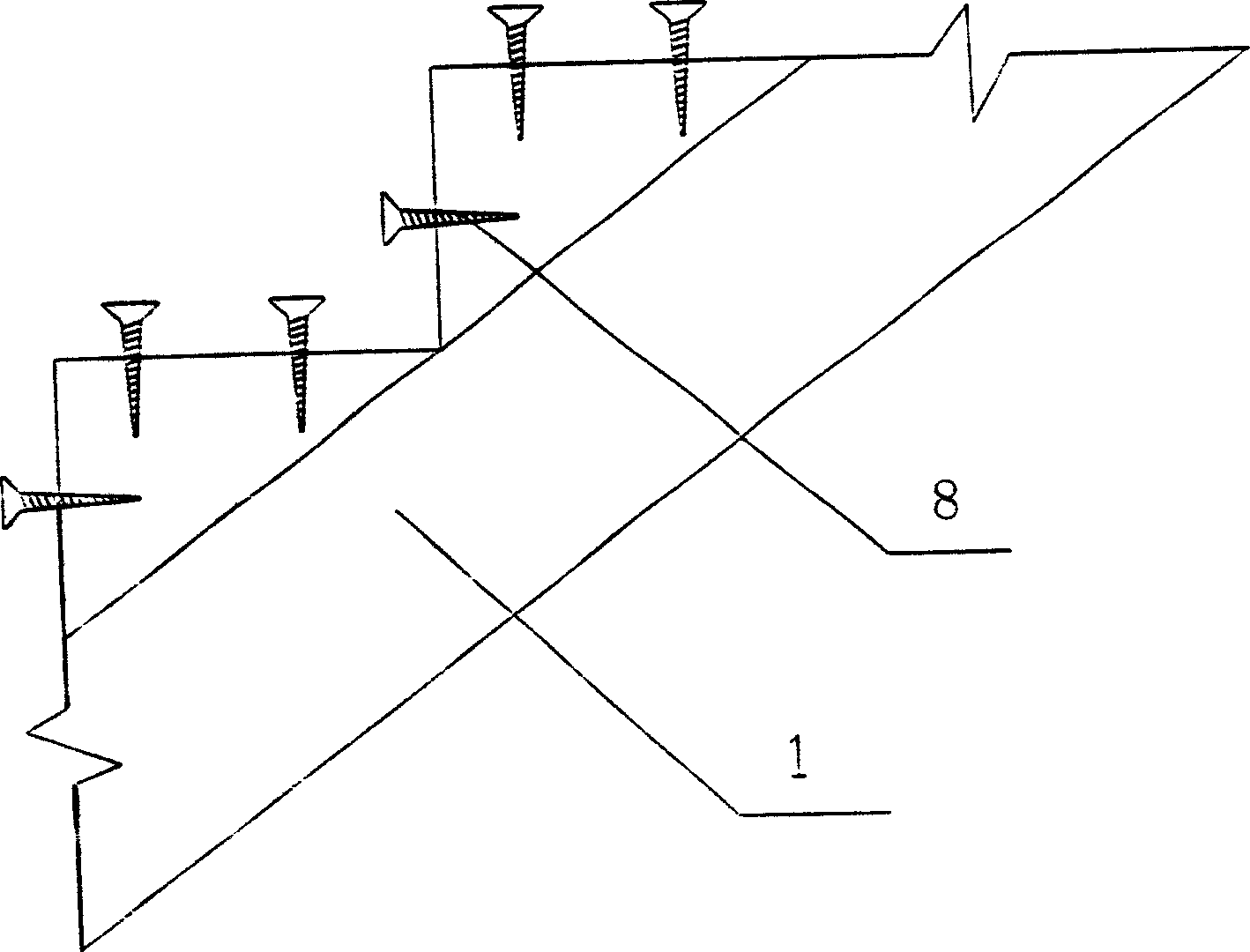

[0025] A new type of assembled structure wooden staircase, including stair treads 2 and a riser 9 between two treads 2 and a beam plate 1 for carrying the treads 2 and risers 9, as shown in Figure 1, the step The left and right ends of the upper surface of the plate 2 are respectively provided with a bolt through hole 3 for fixing the railing. Such as figure 2 Shown, stair beam plate 1 is provided with several screw holes on the contact surface of tread plate 2 and vertical plate 9, and connecting screw 8 is assembled in the screw hole, and the depth of screw hole is 2 / 3 of screw 8 total length.

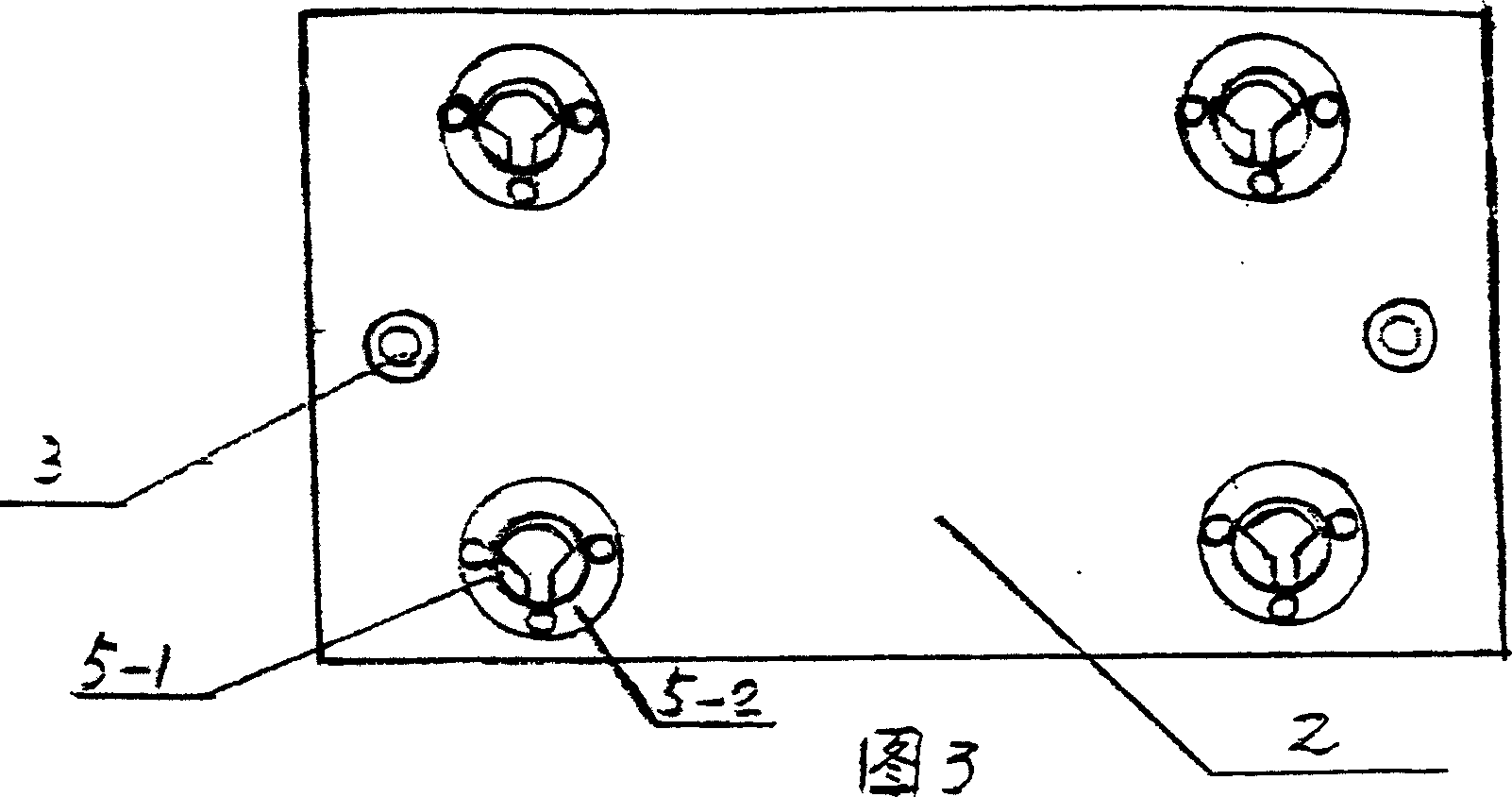

[0026] As shown in Figures 3, 4, and 5, the bottom surface of the tread plate 2 and the inner surface of the vertical plate 9 are provided with several grooves 4 whose sections are stepped, wherein the bottom surface of the tread plate 2 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com