Utensil fatigue test equipment

A fatigue test and utensil technology, applied in the direction of applying repetitive force/pulse force to test the strength of materials, etc., to achieve the effect of light weight, small size and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

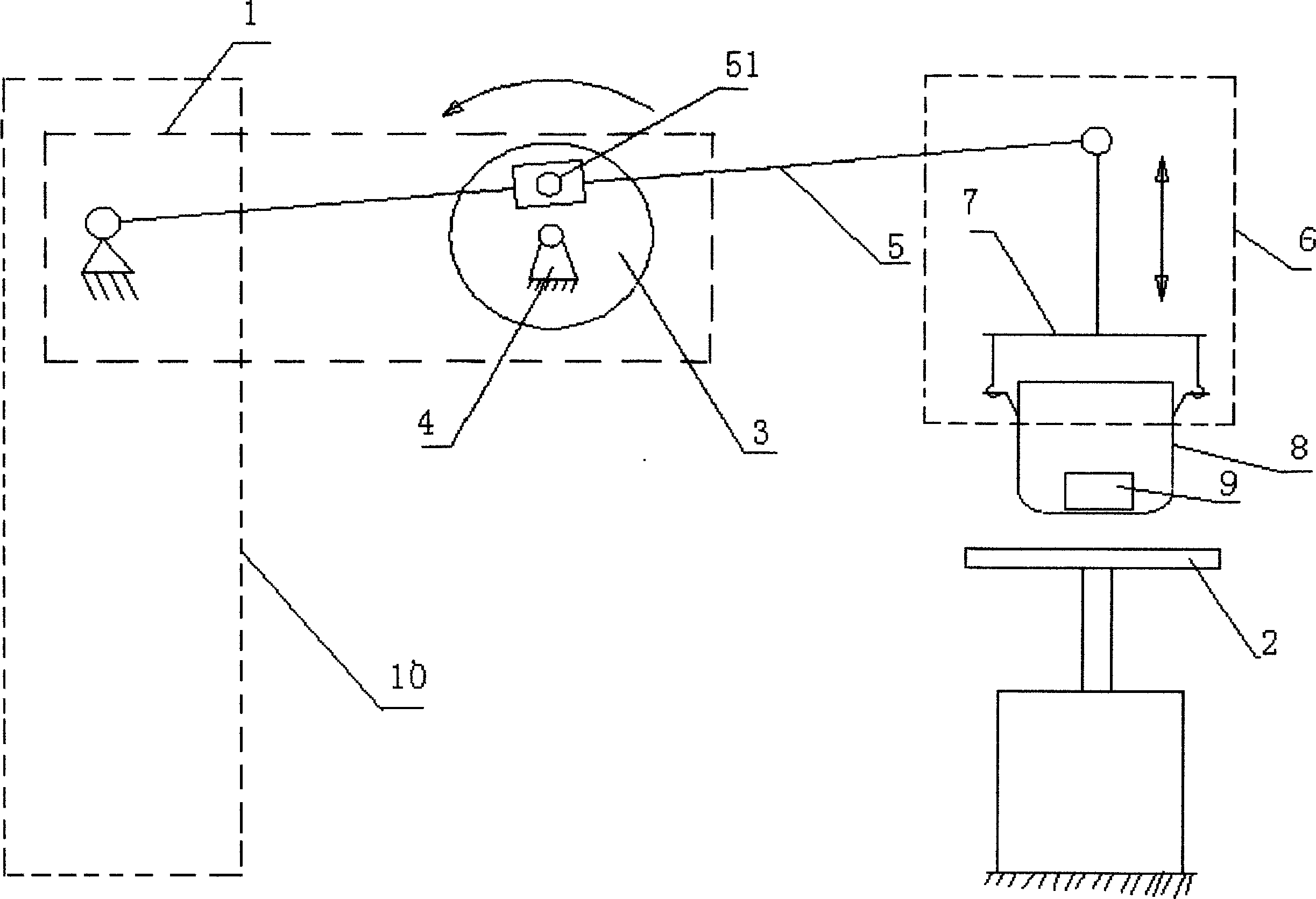

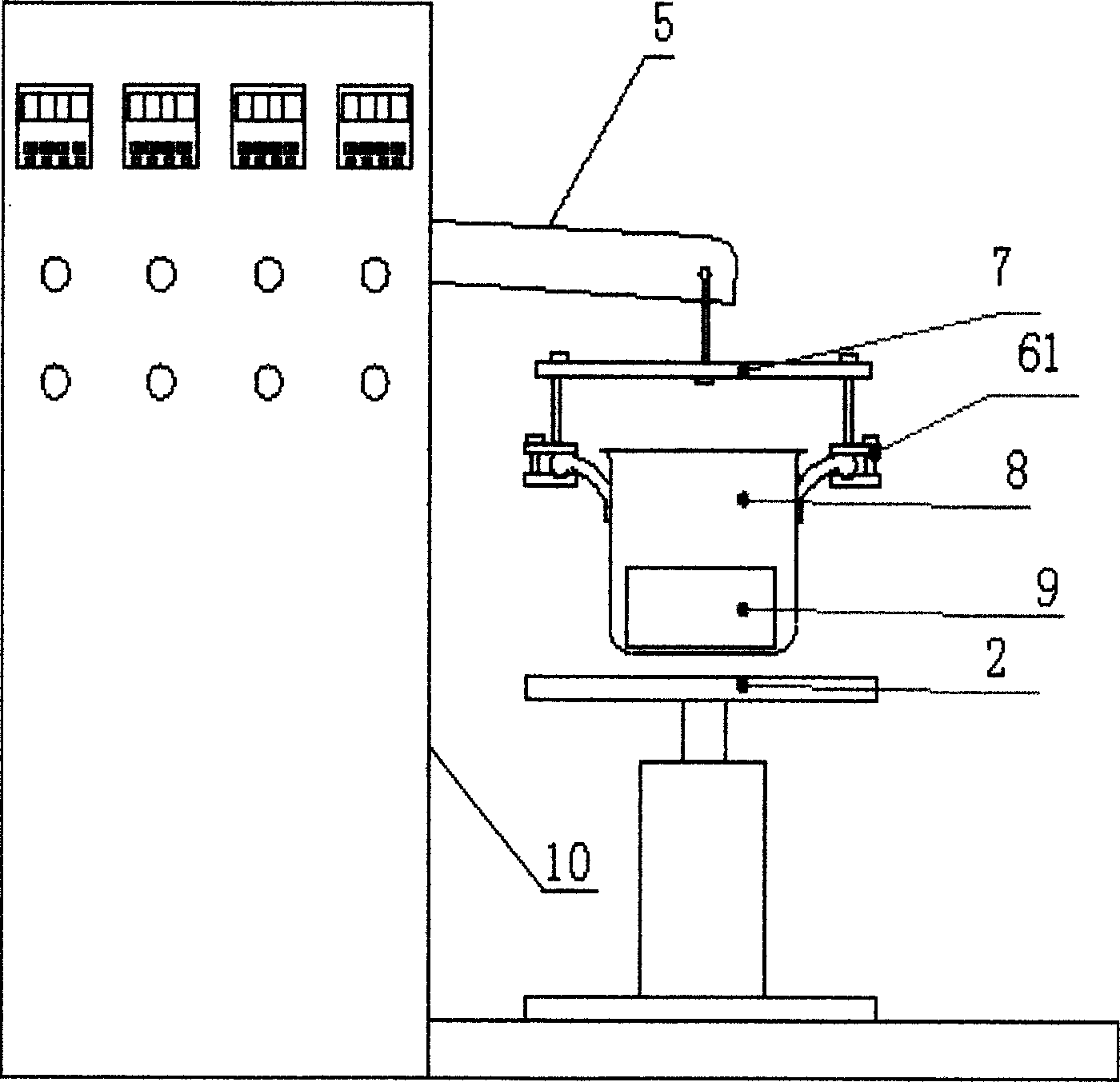

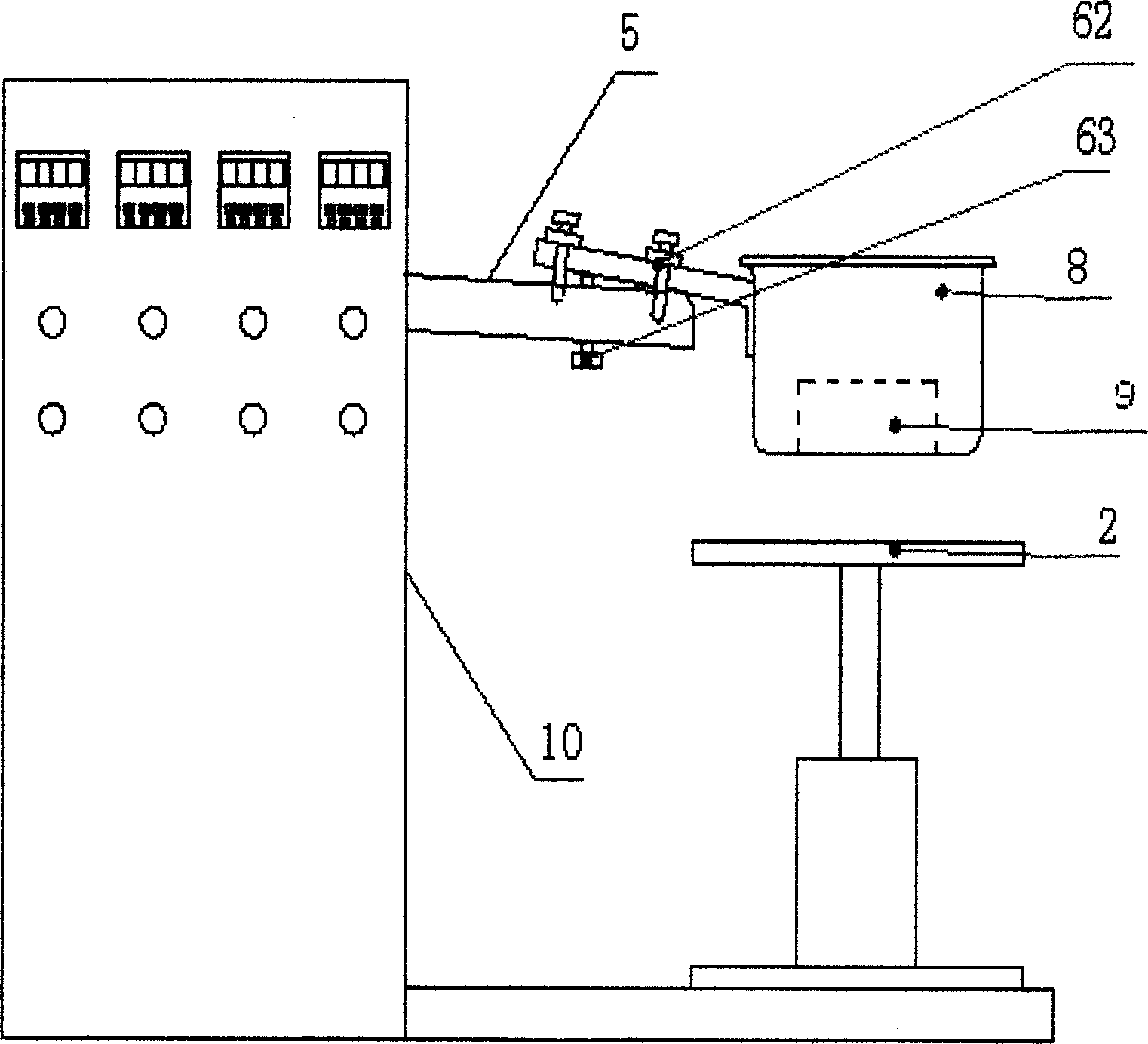

[0019] In the cabinet provided with the control system device 10, the machine base 1 and the lever 5 are installed. One end of the lever 5 is fixed on the machine base 1, and the other end stretches out of the cabinet to become a cantilever. The force point 51 in the middle of the lever can be used as an ellipse Because one end of the lever is fixed on the machine base, at this time, the cantilever end reciprocates up and down with the rotation of the eccentric wheel. A clamping and hanging device 6 is arranged at the cantilever end, and the clamping and hanging device 6 has two forms. When the vessel sample 8 has double ear handles, it includes a hanger 7 and an ear clamp 61, and the ear clamp 61 is connected to the hanger On, fix the two ear handles of the vessel with the ear clamps 61, keep the bottom of the vessel level, and then tighten the ear clamps. When the vessel sample 8 has a single handle, the clamping and lifting device includes a handle clamp 62 and an adjusting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com