Three-cavity packaging shield box for microwave filter and method for producing same

A microwave filter and filter technology, which is applied to waveguide devices, electrical components, circuits, etc., can solve the problems of inconvenient design and production, inconsistent welding, and low filter yield, so as to reduce adverse effects and improve product quality. efficiency, solve the effect of difficult assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

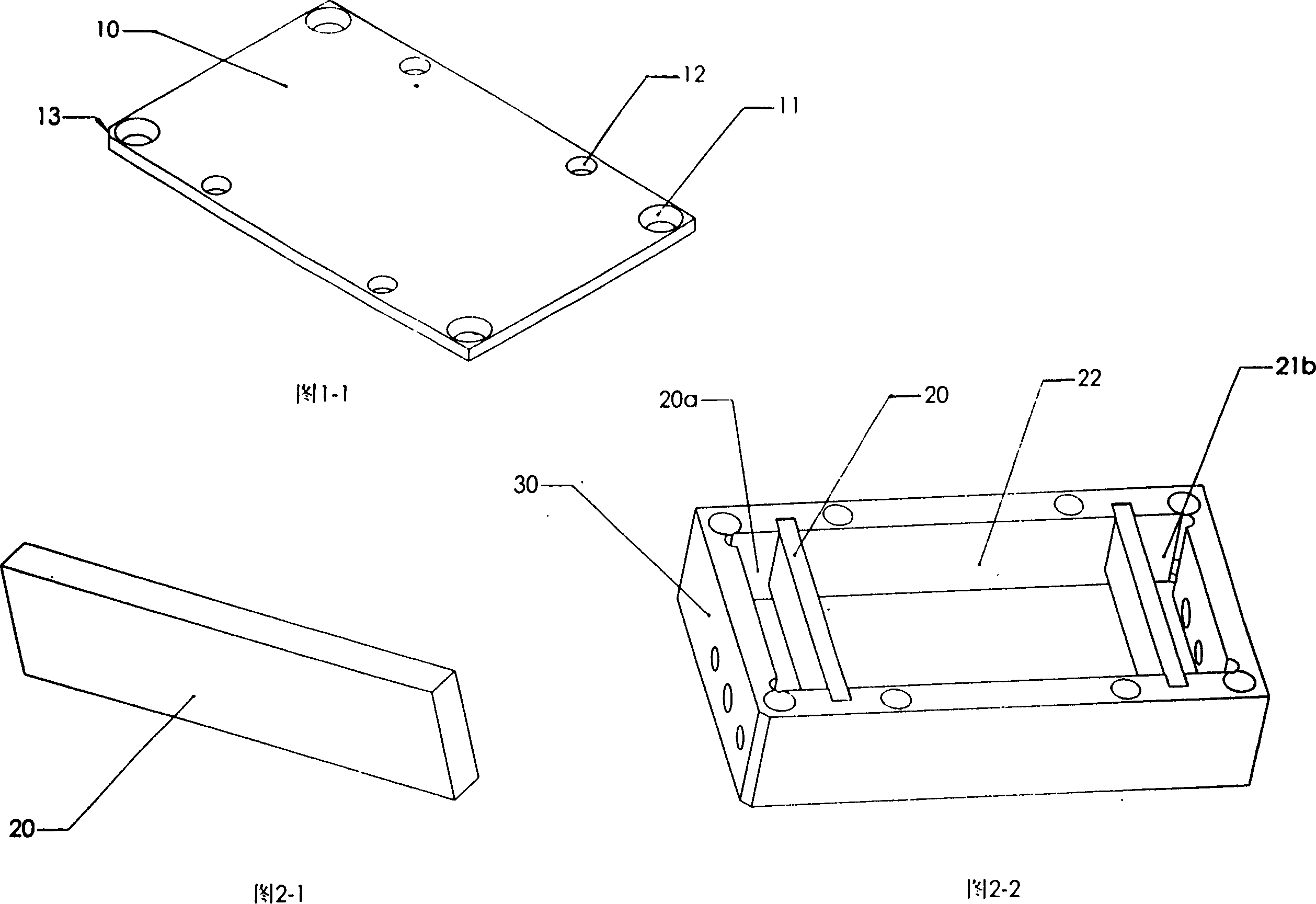

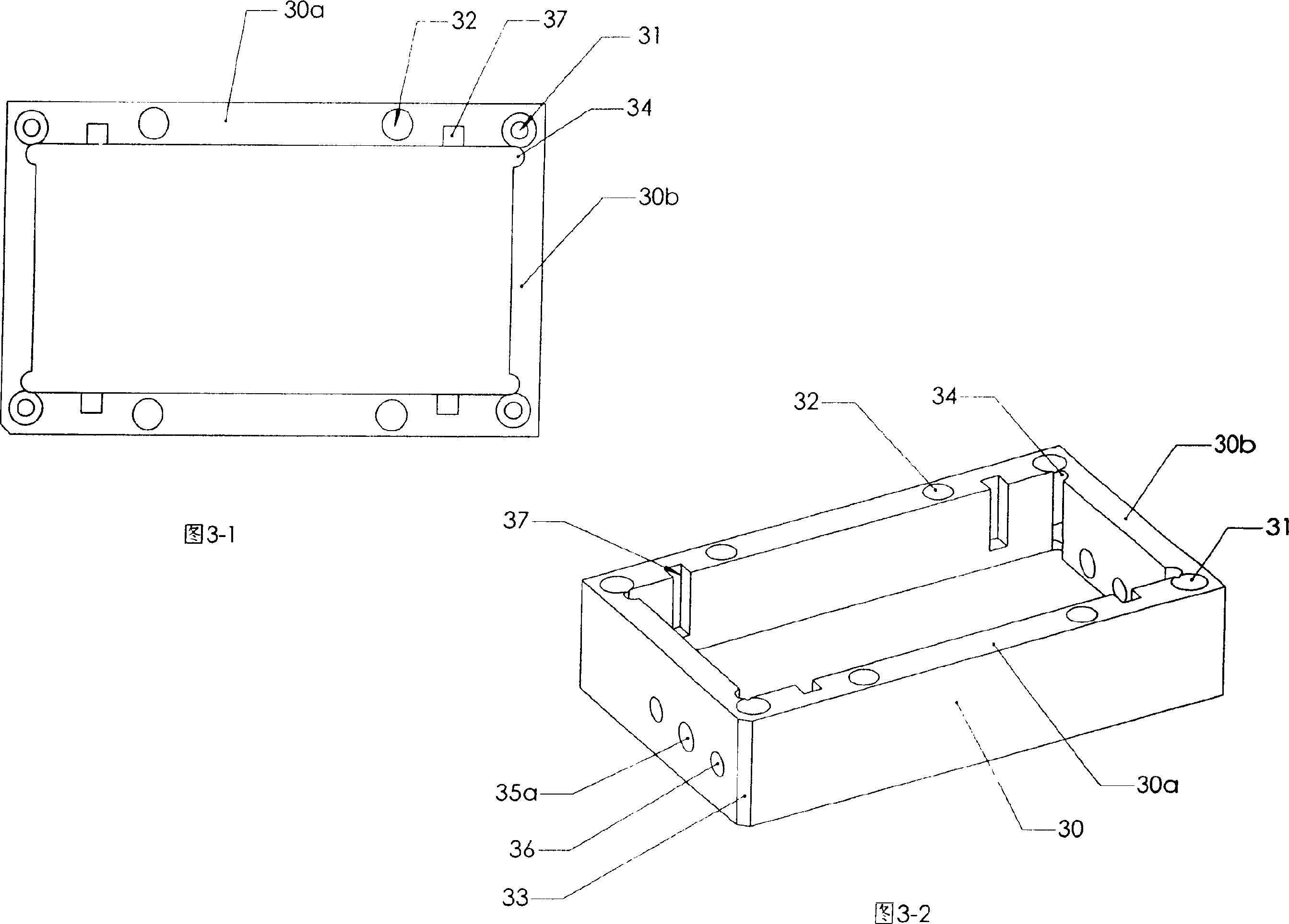

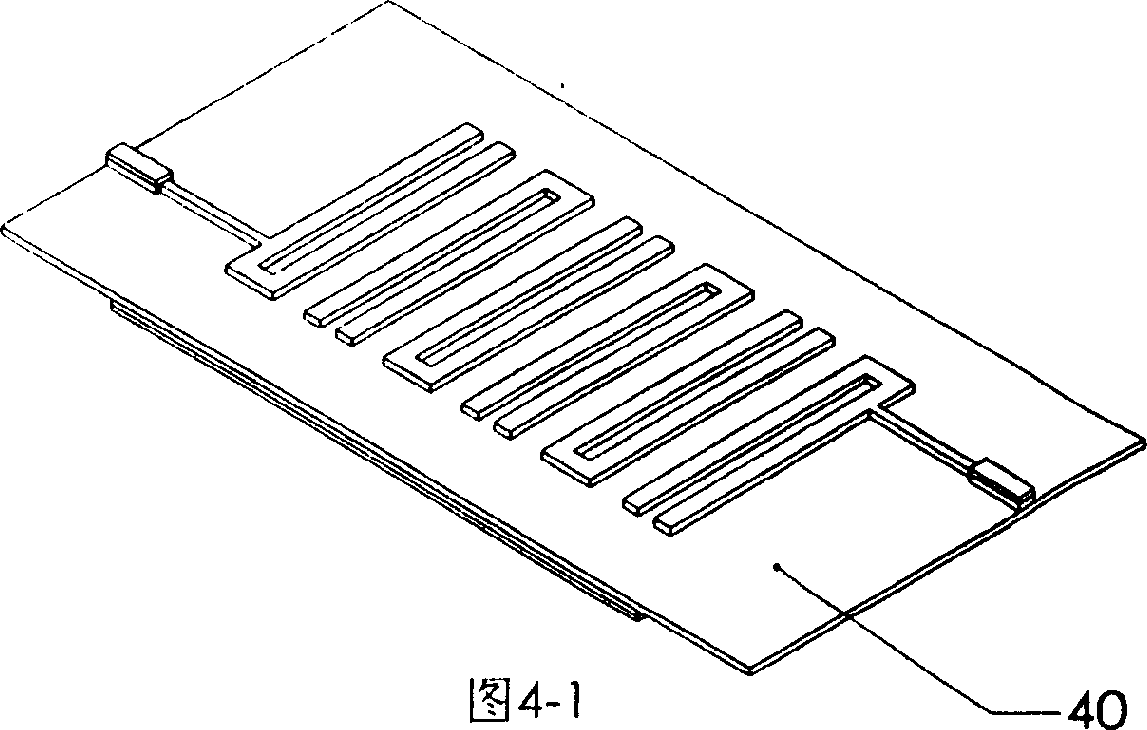

[0024] Embodiment: A microwave filter three-cavity package shielding box (see Figure 1-1~ Figure 5-2 ), including box cover 10, filter box base 30, filter work piece 40 and standard SMA joint 51, it is characterized in that on the filter box base 30, two insertable filter activities are assembled according to the positioning slot 37 The shielding partition 20 and the box base 30 are symmetrically separated by the movable shielding partition 20 of the two filters into a three-cavity packaging shielding box (see Fig. 2-2); Circuit 42, working sheet dielectric layer 43, working sheet bottom superconducting material layer 44, working sheet bottom gold-plated layer 45 constitute the filter working sheet 40 in sequence, the superconducting material layer 44 at the bottom and the working sheet bottom gold-plated layer 45 Stopping at the end of the intermediate filter shielding cavity separated by the movable shielding partitions 20 of the two filters, two filter solder joint shieldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com