Piezoelectric vibration gyro element, method for manufacturing the same, and piezoelectric vibration gyro sensor

A piezoelectric vibrating gyroscope and a manufacturing method technology, applied in piezoelectric devices/electrostrictive devices, manufacture/assembly of piezoelectric/electrostrictive devices, components of piezoelectric devices or electrostrictive devices, etc., It can solve problems such as reduced productivity and yield, overexposure, light source configuration change and troublesome positioning of masks, etc., to achieve the effect of ensuring symmetry and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, best embodiments of the present invention will be described in detail with reference to the drawings.

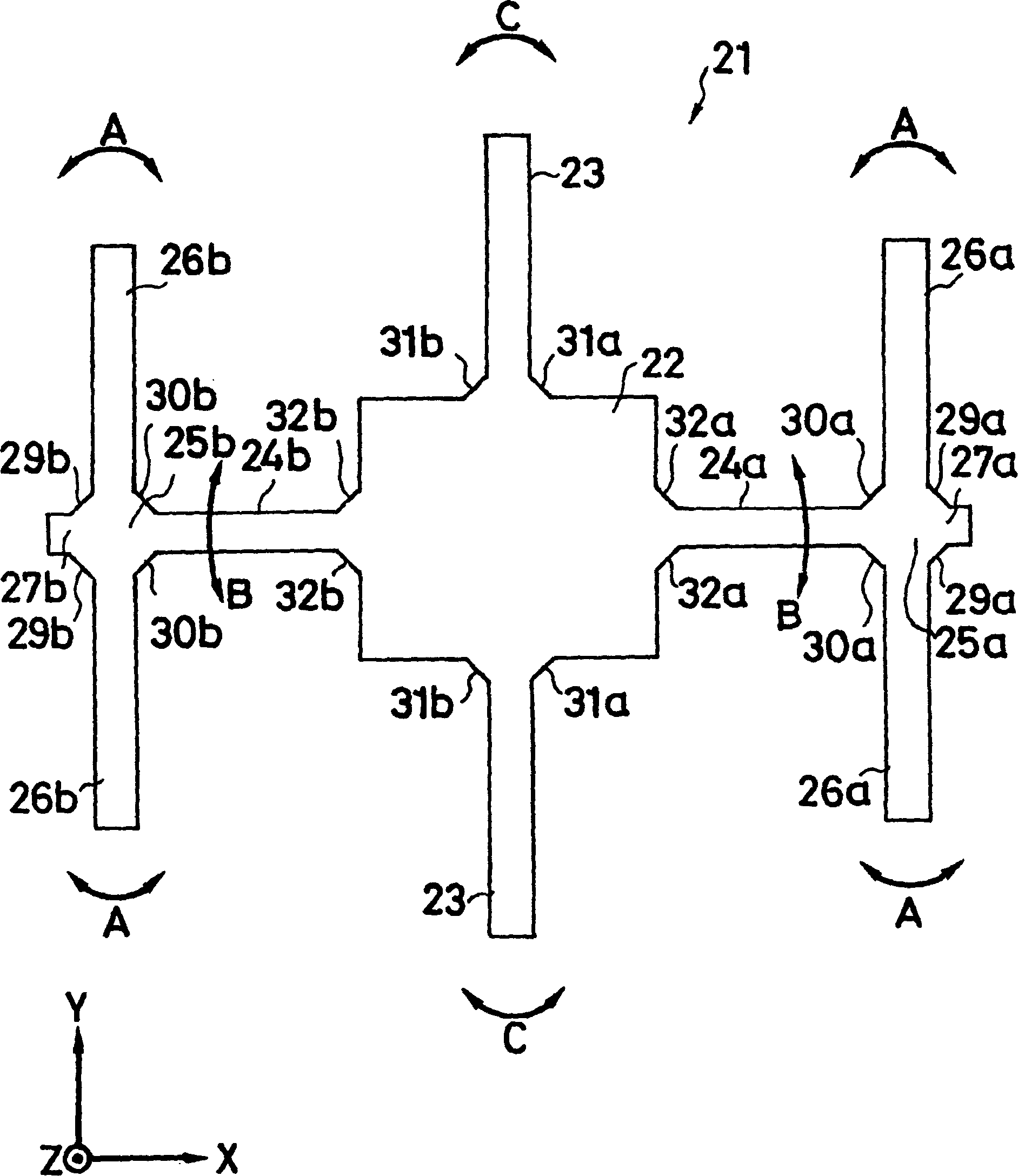

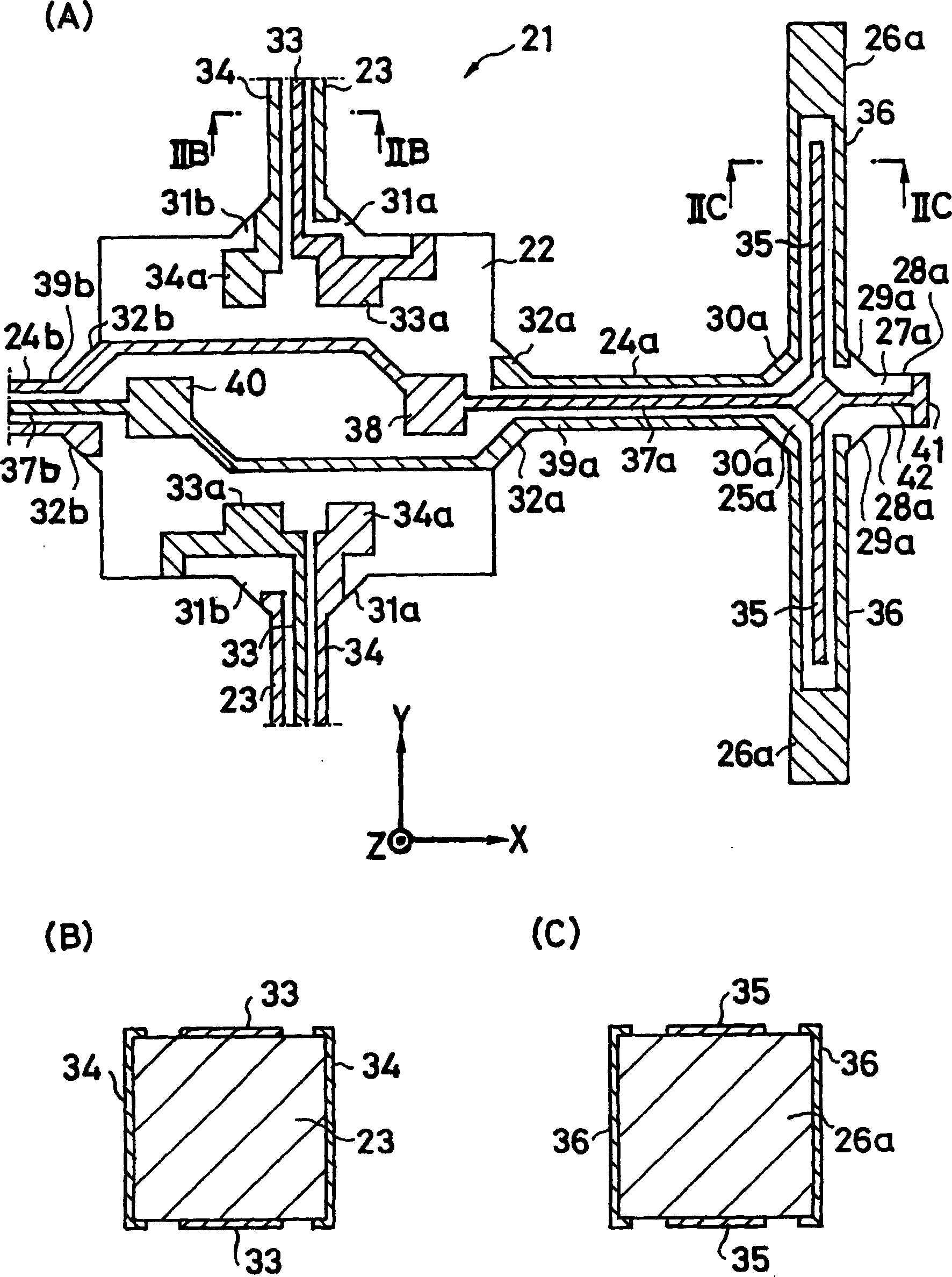

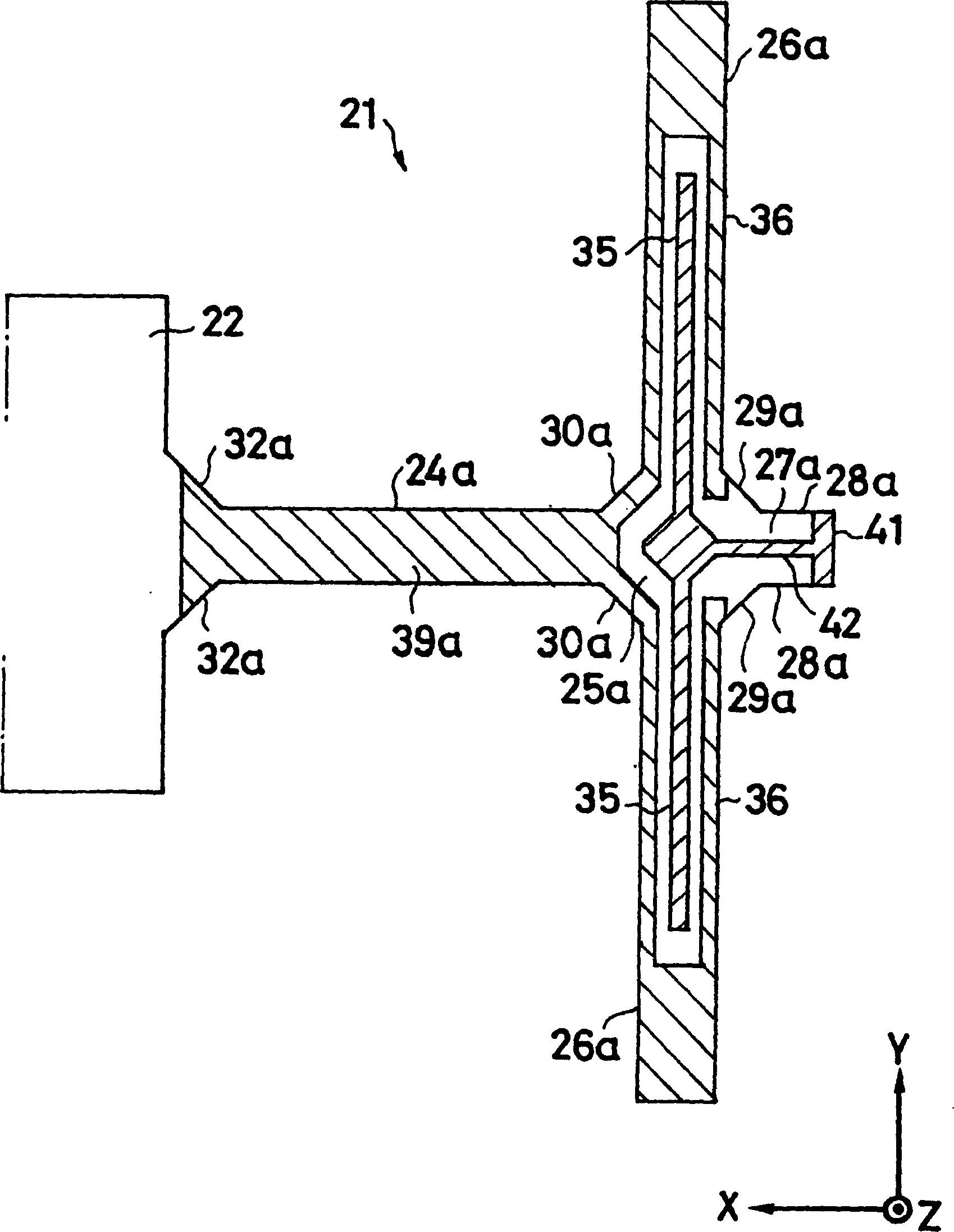

[0053] figure 1 The piezoelectric vibrating gyro element 21 of the present invention is schematically shown. The piezoelectric vibrating gyro element 21 has a pair of detection and vibrating arms 23 , 23 extending from the center of the upper and lower sides of the substantially square central support portion 22 to both upper and lower sides, respectively, as a detection vibration system. In addition, the piezoelectric vibrating gyro element 21 has, as a drive vibration system, a pair of connecting arms 24a, 24b extending from the center of the left and right sides of the central support part 22 to the left and right sides and in a direction perpendicular to the detection vibrating arm. and a pair of left and right driving vibrating arms 26a, 26a, 26b extending up and down on both sides in a direction perpendicular to the connecting arms and in parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com