Wired circuit board

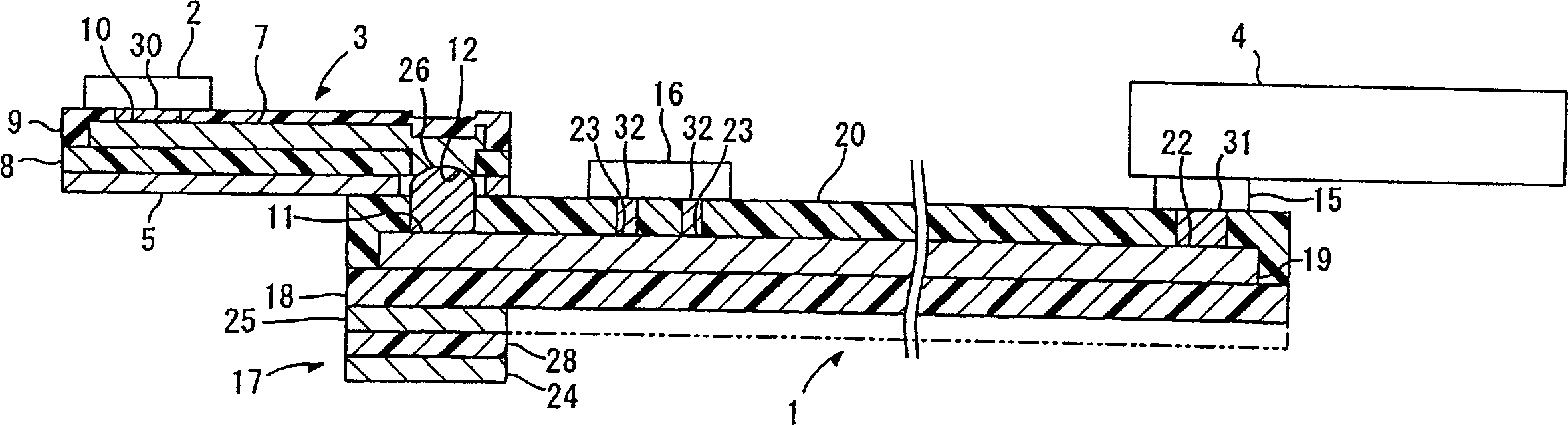

A technology for wiring circuit boards and circuits, which is applied in the direction of circuit substrate materials, laminated printed circuit boards, printed circuits, etc., to achieve the effect of improving signal transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

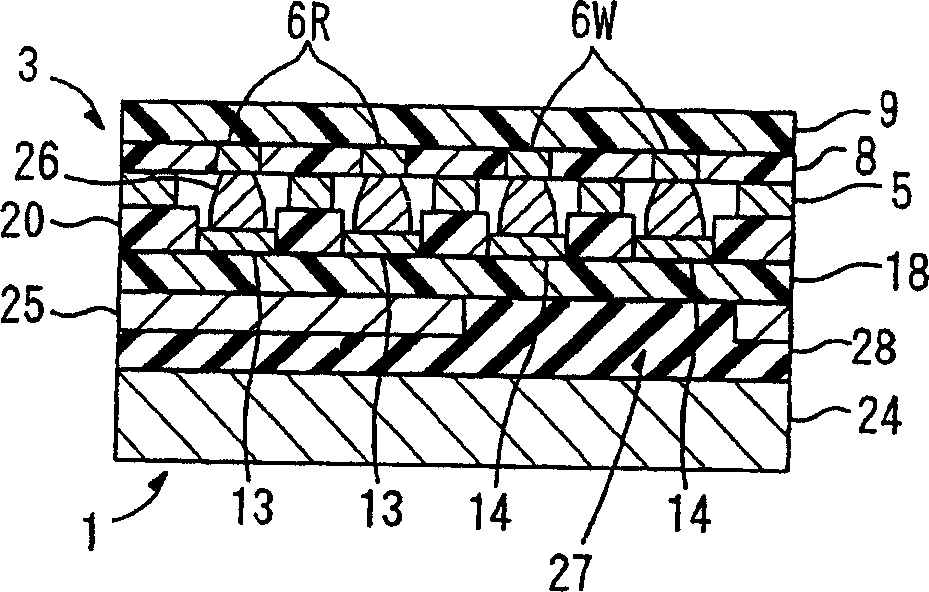

[0073] A double-sided copper-clad laminate sheet (ESPANEX (product name) available from Nippon SteelChemical Co., Ltd.) having 12.5-µm-thick copper on both sides of a 12.5-µm-thick polyimide sheet was prepared. Flakes.

[0074] After covering the double-sided copper-clad laminate with a dry film photoresist, the dry film photoresist is exposed to light, and then developed to form a resist pattern to cover the formation part of the wiring circuit pattern and the conductive layer. The forming part of the plate.

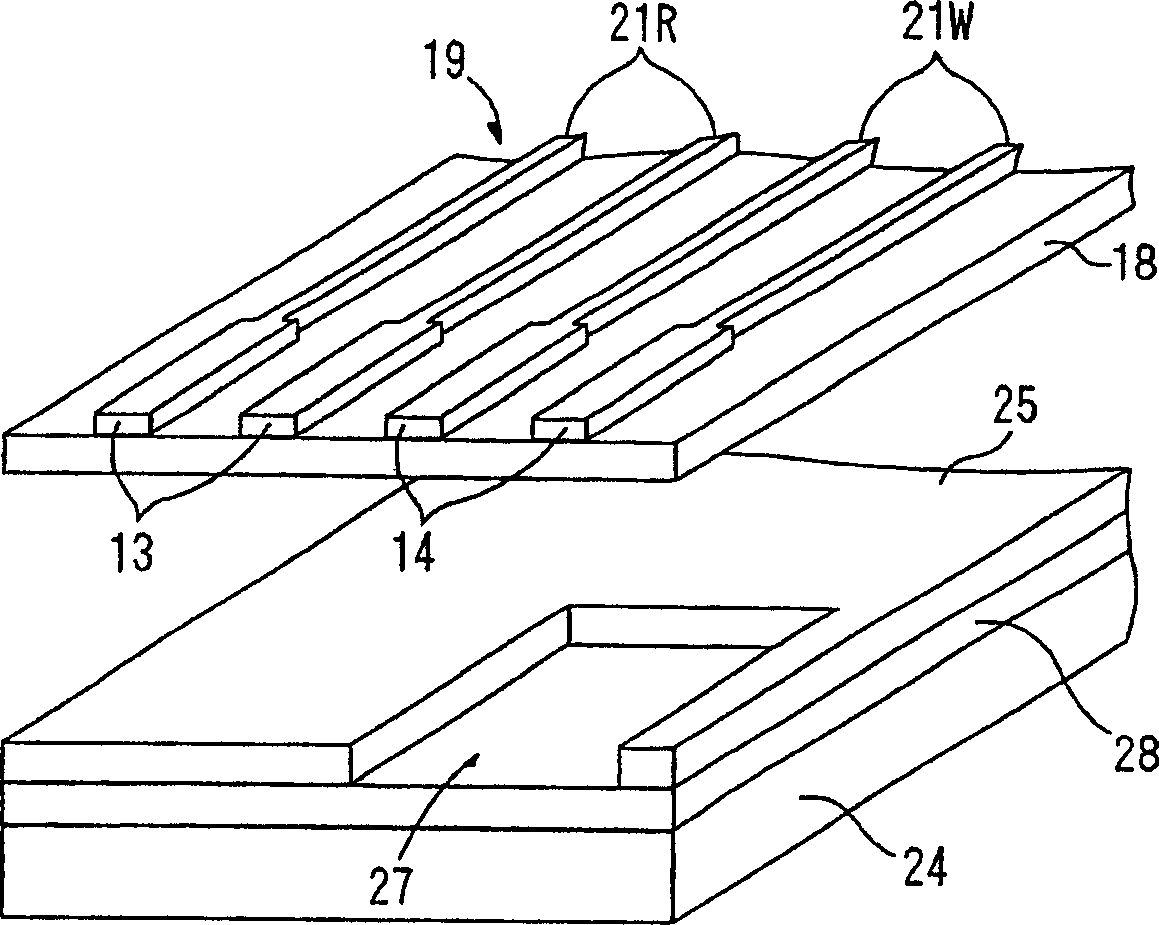

[0075] Then, after etching the copper foil exposed from the resist, the resist is removed, thereby forming a conductive layer having a wiring circuit pattern of a readout line and a write-in line on one side of the polyimide sheet, and the readout The lines and the write lines respectively have a first terminal portion and a second terminal portion, and a conductive plate having an opening hole overlapping each second terminal portion is formed at a part thereof on the...

example 2

[0078] A single-sided copper-clad laminate sheet (ESPANEX (product name) available from Nippon Steel Chemical Co., LTD.) having a 12.5-µm-thick polyimide sheet on one side with a 12.5-µm-thick copper flakes.

[0079] After covering the one-side copper-clad laminated sheet with a dry thin film photoresist, the dry thin film photoresist is exposed to light and then developed to form a resist pattern to cover the wiring circuit pattern forming portion.

[0080] Then, after etching the copper foil exposed from the resist, the resist is removed, thereby forming a conductive layer having a wiring circuit pattern of a readout line and a write-in line on one side of the polyimide sheet. The outgoing and writing lines have first and second terminal portions, respectively.

[0081] Thereafter, a generally rectangular aluminum sheet with a thickness of 100 μm, having an opening hole preformed by punching and having a thickness of 10 μm, is adhesively bonded to polyimide in such a relati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com