Electric vortex contactless approaching track shaft-metering device

A non-contact, eddy current technology, applied in the direction of material magnetic variables, etc., can solve the problems of difficult installation, low reliability, easy to wear, etc., to achieve the effect of broadening the application, reducing interference, and improving the detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

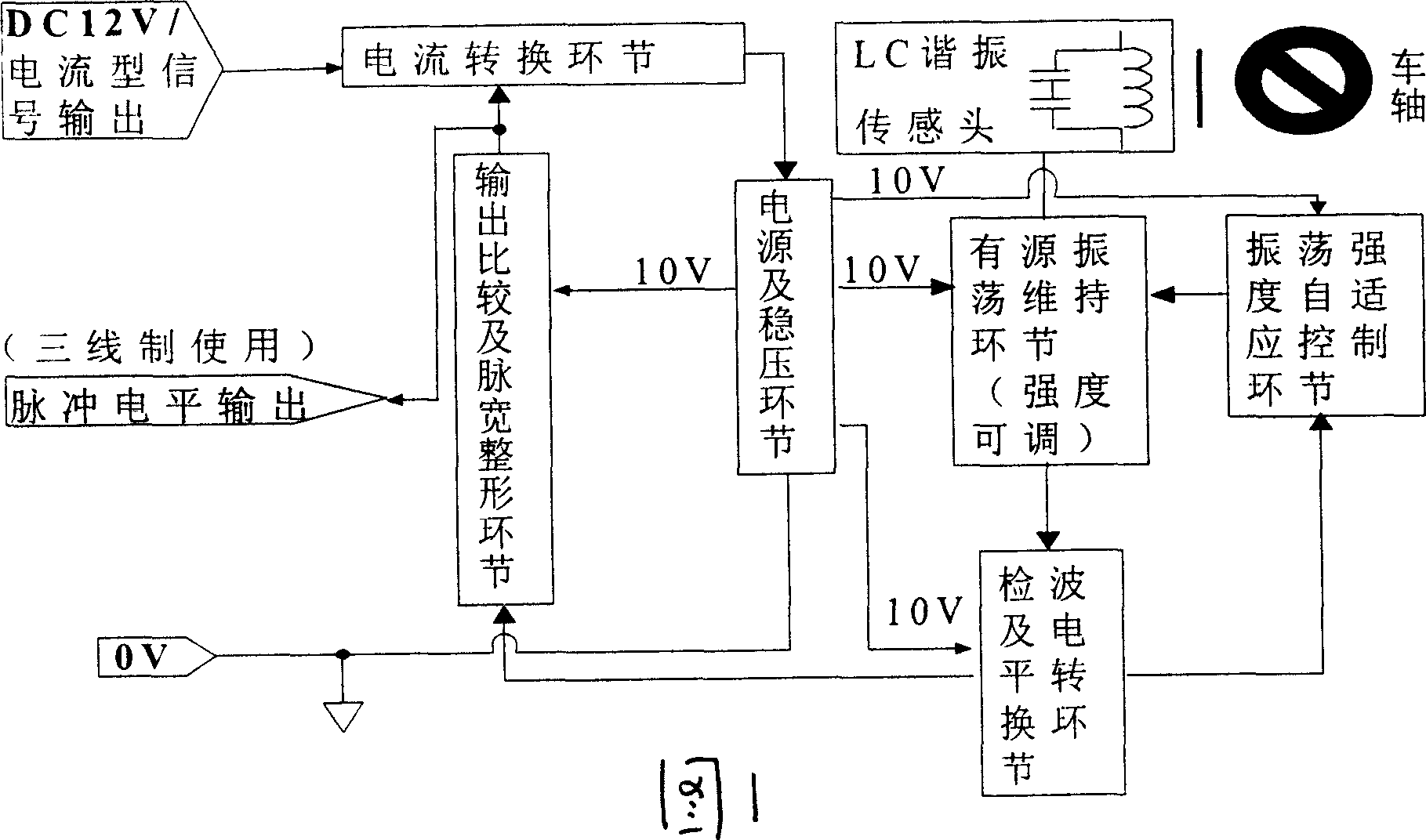

[0055] The eddy current non-contact adjacent track axle counter includes a sensor, an active oscillation maintenance circuit unit, a detection and level conversion circuit unit, an output comparison and pulse width correction circuit unit, a current conversion circuit unit, a power supply and a voltage stabilization circuit unit and Oscillation intensity adaptive control unit, see Figure 1.

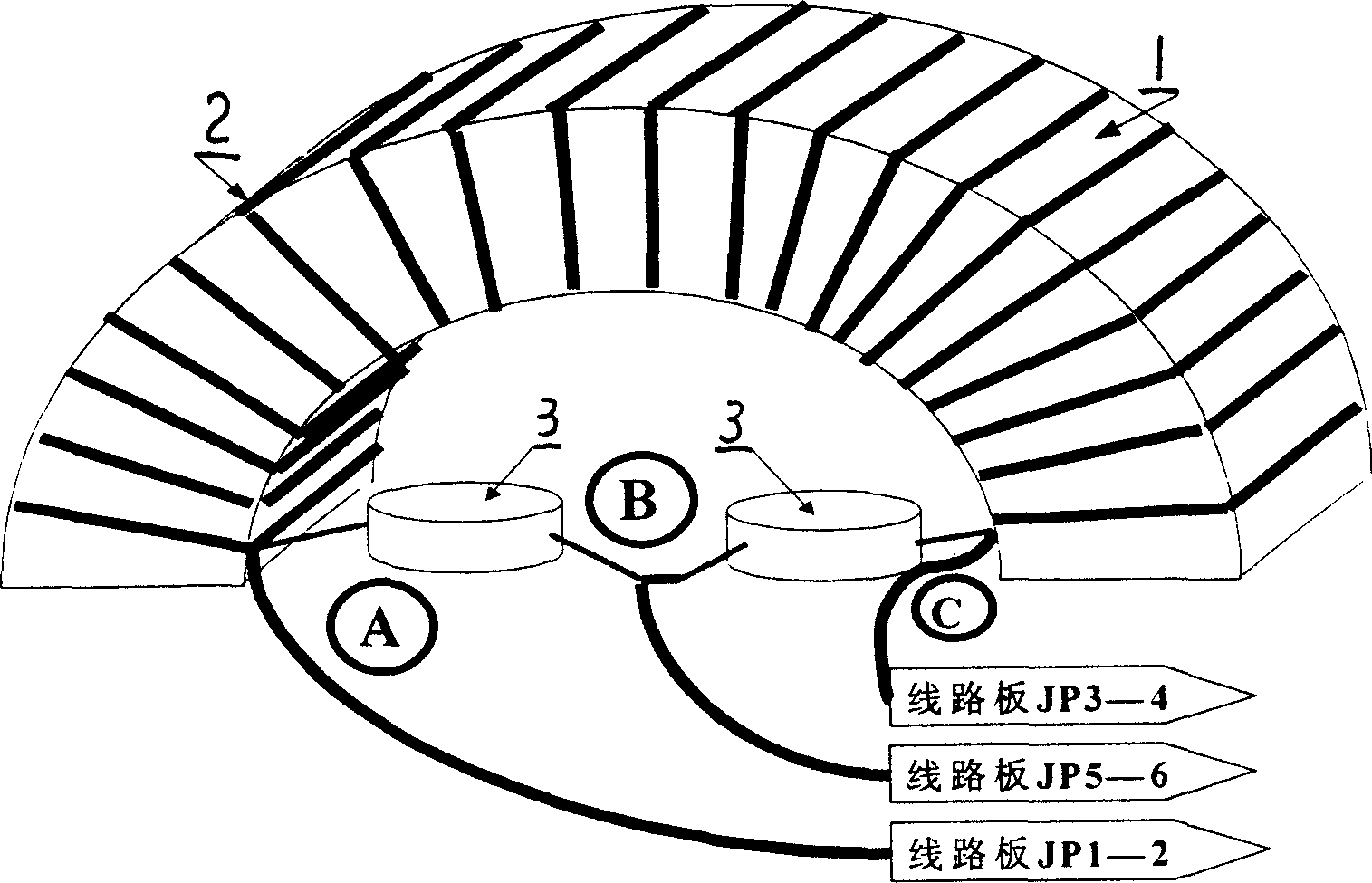

[0056] see figure 2 , the sensor includes a semi-annular open magnetic body 1, a sandbag multi-strand copper core wire 2 and two capacitors 3, the sandbag multi-strand copper core wire 2 is evenly wound on the semi-annular open magnetic body 1, and two capacitors 3 are connected in parallel to the sandbag At both ends of the multi-strand copper core wire 2, the capacitance values of the two capacitors are 1000pF and 10000pF respectively; they together form an LC resonant circuit, and the three wires drawn from A, B, and C are respectively connected to the active oscillation maintenance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com