Rare earth contained perfluorocarboxylic Lewis acid catalyst and its preparation

A perfluorocarboxylic acid, rare earth metal technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of expensive ligands, reduced catalytic activity, etc. problems, to achieve the effect of broad prospects, easy availability of raw materials, industrial production and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

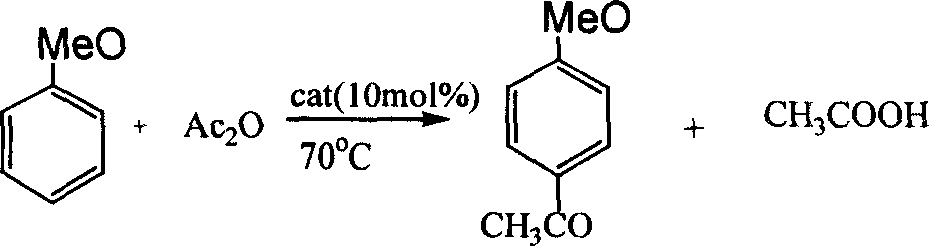

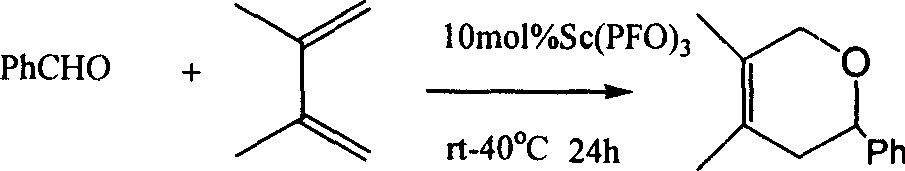

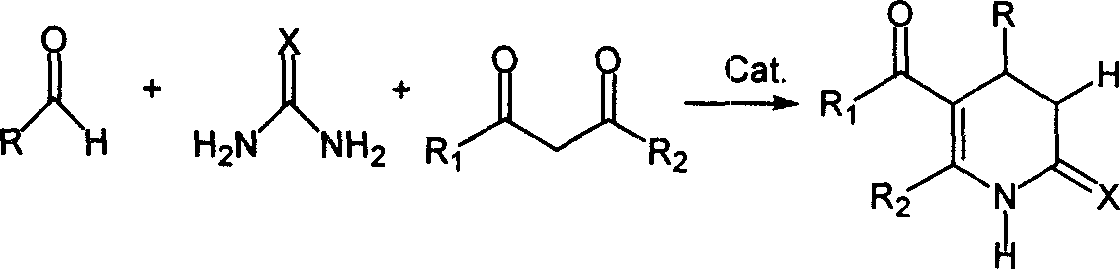

Method used

Image

Examples

Embodiment 1

[0021] Catalyst [CF 3 (CF 2 ) 6 COO] 3 Preparation of La:

[0022] Perfluorooctanoic acid (2.1g, 0.005mol) and La 2 o 3 (0.26g, 0.00083mol) was added into a 25ml single-port reaction flask, 10ml of deionized water was added with a syringe, heated and stirred, the temperature was raised to boiling, and the condenser was refluxed. Keep warm at 100°C, react for 6-8 hours, stop heating, cool to room temperature to obtain 2.3 g of white spherical solid, wash twice with water, and dry under vacuum to obtain the target product. Yield 100%. IR (KBr) 3400-3500, 1650-1700(s), 1200(s), 1150(s); ICP-ABS: La 3+ (11%);. 19 FNMR: -81((9F), -116(6F), -122.3(6F), -122.7(12F), -123.51(6F).

[0023]

Embodiment 2

[0025] Dissolve lanthanum acetate (0.468g, 0.00167mol) in 5ml of deionized water, add perfluorooctanoic acid (2.1g, 0.005mol), stir for 30min, heat up to 100°C, filter to remove water, and vacuum dry to obtain a white solid with a yield of 99%.

[0026]

Embodiment 3

[0028] Dissolve perfluorooctanoic acid (2.1g, 0.005mol) in 10ml of water first, then add anhydrous LaCl 3 (0.4g, 0.0017mol) or LaCl 3 ·6H 2 O (1.7g, 0.0017mol) was heated to 120°C, stirred vigorously for 19h, filtered to remove water, washed with deionized water several times, and then dried to obtain a white solid with a yield of about 80%.

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com