Method for accelerating preparation of alloy coating

A technology of alloy coating and heating furnace, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problems of limited effect, weak impact of small particles, and high heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Test device

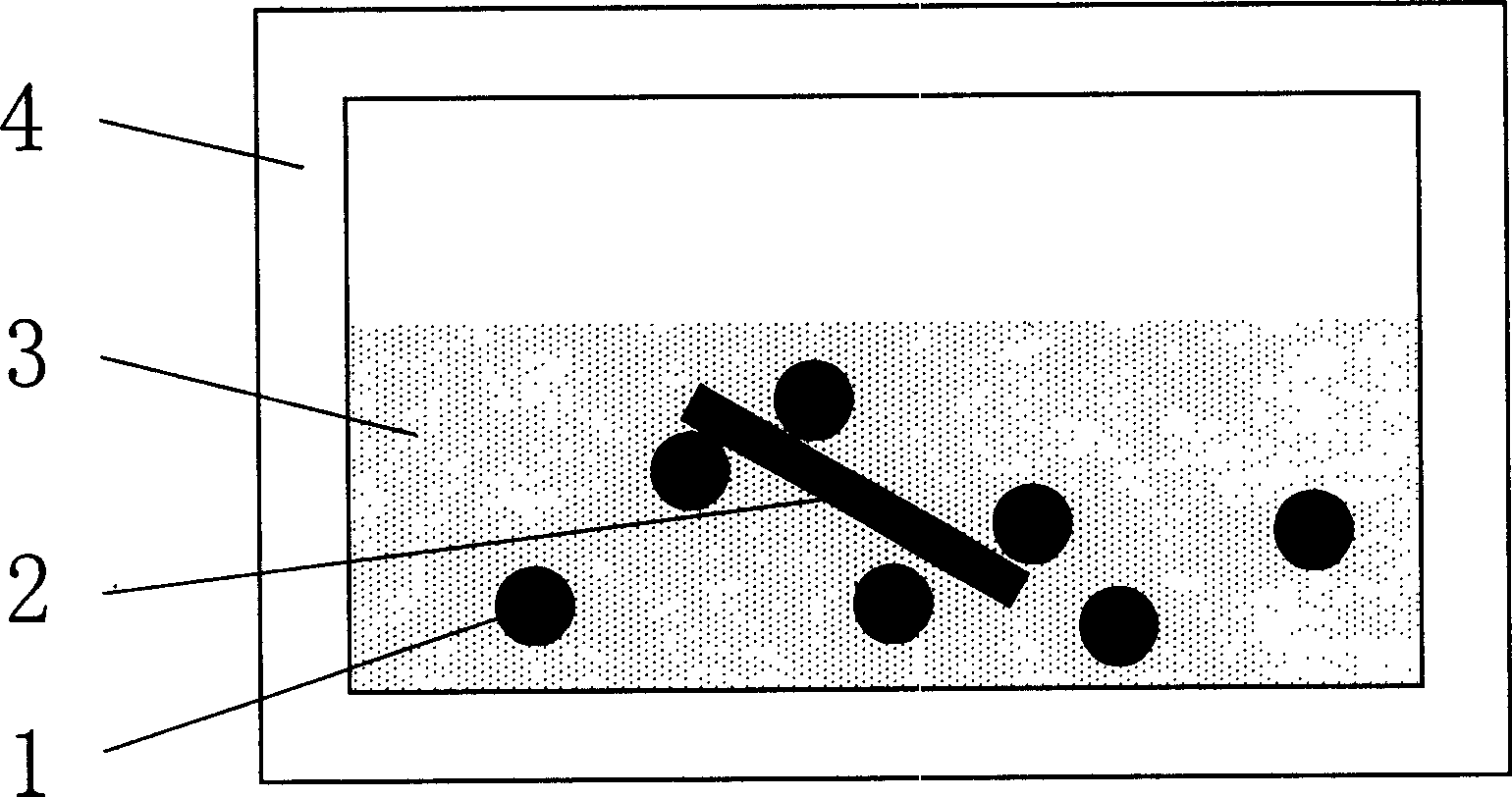

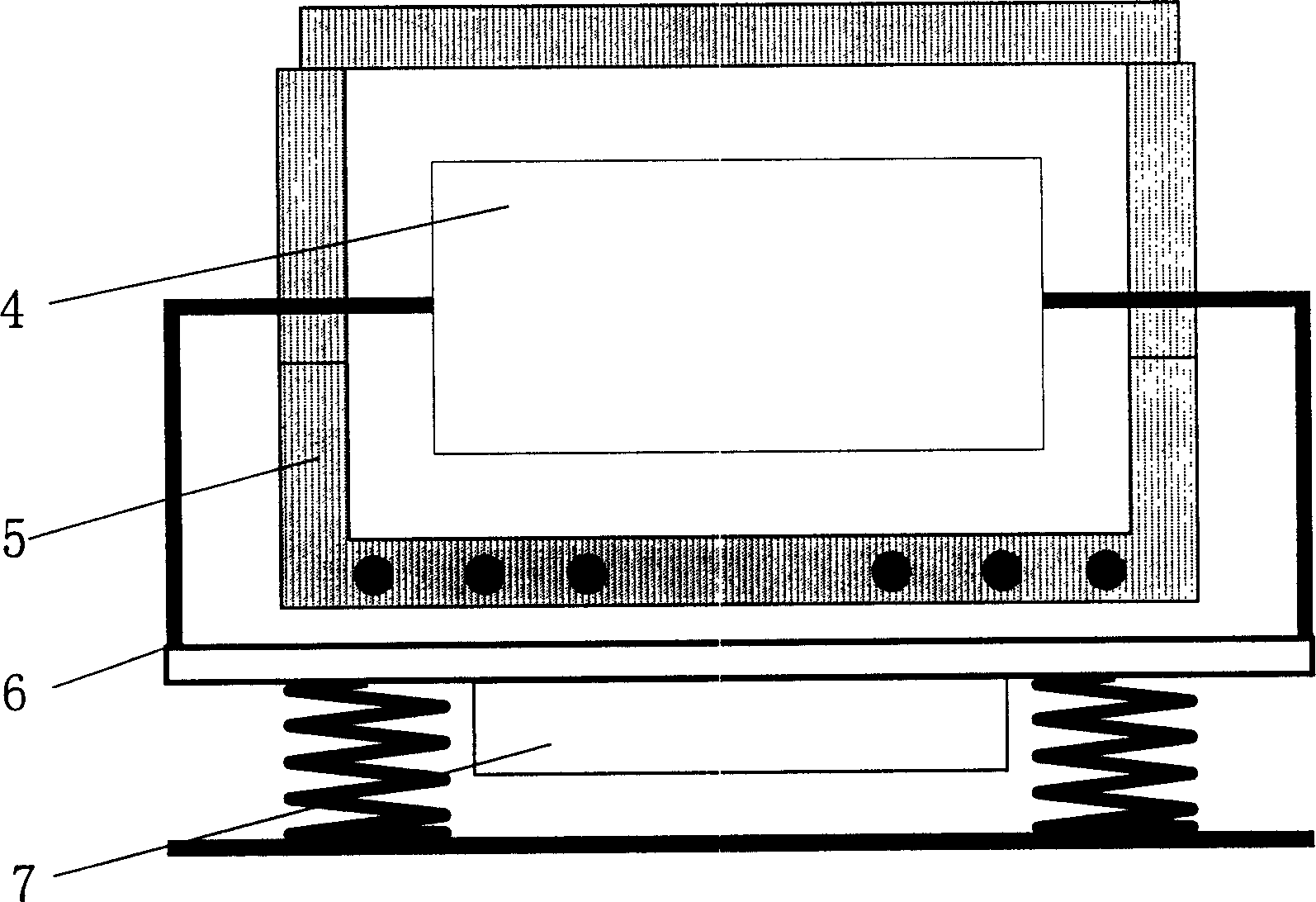

[0025] according to figure 1 As shown, the medium ball 1, the freely placed sample 2, and the composite powder 3 are mixed together and placed in a closed container 4. The closed container is mounted on a mechanical vibrating device such as figure 2 As shown, the mechanical vibrating device 7 is an inertial vibration, which is composed of an eccentric block driven by a motor. The weight and eccentricity of the eccentric block can be adjusted; The device is connected, and the closed container 4 is placed in the heating furnace 5 to be heated, so that the closed container 4 vibrates under the heated state.

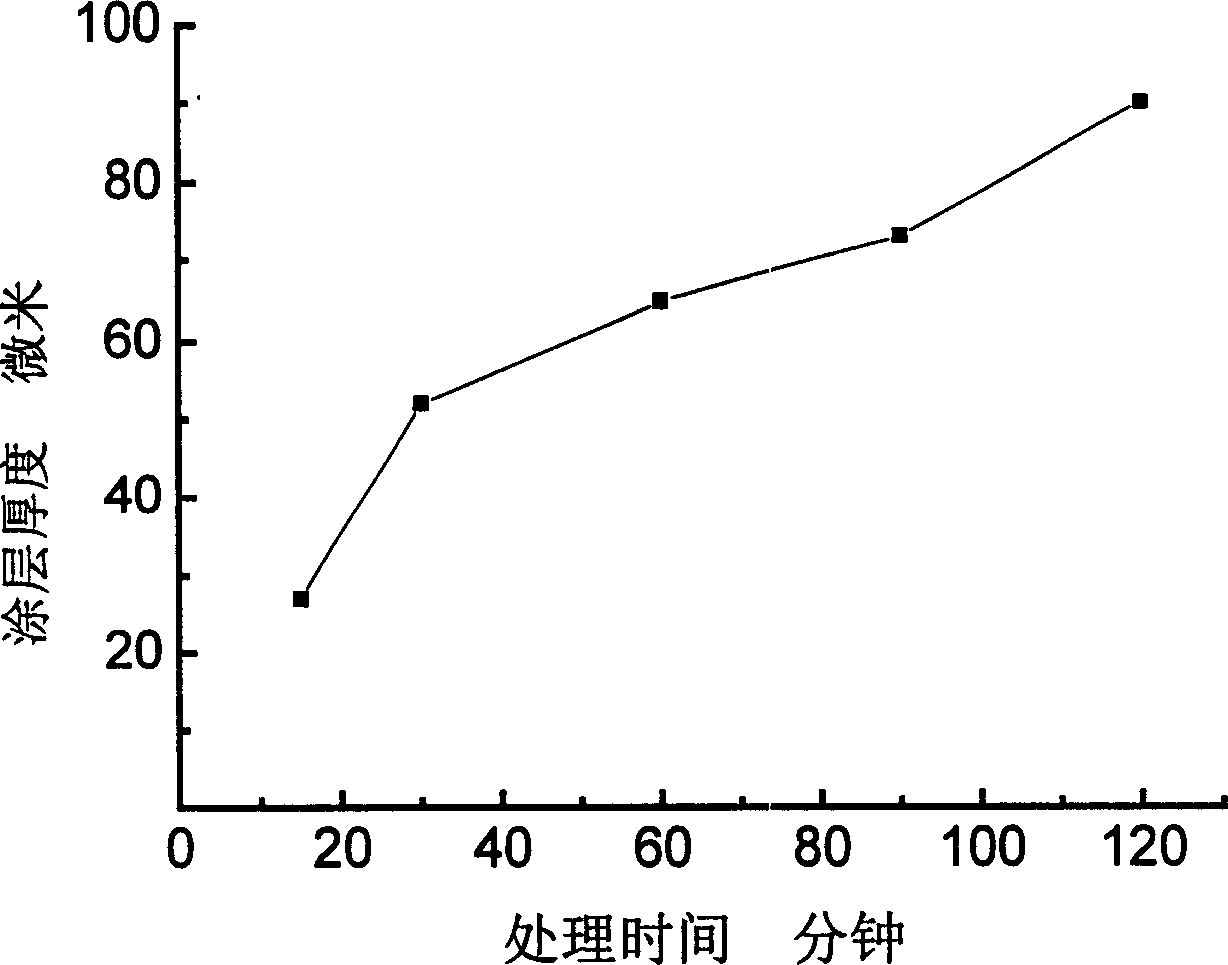

[0026] Treatment process

[0027] The main component (percentage by weight) of the composite powder is 20% aluminum powder (Al, 200 mesh), 76% aluminum oxide (Al 2 o 3 , 200 mesh), 4% ammonium chloride (NH 4 Cl). The dielectric ball is FeCrAl alloy ball with a diameter of 4mm. The ratio of the medium ball to the composite powder is (weight ratio...

Embodiment 2

[0032] The test device is the same as in Example 1.

[0033] Treatment process

[0034] The main component (percentage by weight) of composite powder is 48% aluminum powder (Al, 200 orders), 47% aluminum oxide (Al 2 o 3 , 200 mesh), 5% ammonium chloride (NH 4 Cl). The dielectric ball is FeCrAl alloy ball with a diameter of 4mm. The ratio of the medium ball to the composite powder is (by weight) 10:1, and the filling amount is 1 / 2 of the volume of the closed container.

[0035] Fully mix the composite powder and medium balls and fill them in a closed container, place the No. 20 steel sample and the Cr5Mo sample freely in the closed container, seal the closed container and protect it with argon gas to prevent oxidation. Heating to 440°C-600°C, after reaching the temperature, start the vibrating device, the amplitude is 10mm, the vibration frequency is 25Hz, vibrate for 120 minutes, and cool down with the furnace.

[0036] process result

[0037]After the above treatment, ...

Embodiment 3

[0039] The test device is the same as in Example 1.

[0040] Treatment process

[0041] The main component (percentage by weight) of the composite powder is 15% ferrosilicon powder (Fe-75% Si, 200 mesh), 80% aluminum oxide (Al 2 o 3 , 200 mesh), 5% potassium fluoroborate (KBF 4 ). The dielectric ball is made of FeCrAl alloy ball with a diameter of 6mm. The ratio of the medium ball to the composite powder is (by weight) 8:1, and the filling amount is 3 / 4 of the volume of the closed container.

[0042] Fully mix the composite powder and medium balls and fill them in a closed container, place the 20 steel sample freely in the closed container, seal the closed container and protect it with argon gas to prevent oxidation. Heating to 520°C, after reaching the temperature, start the vibrating device with an amplitude of 5 mm and a vibration frequency of 25 Hz, vibrate for 120 minutes, and cool with the furnace.

[0043] process result

[0044] After the above treatment, a sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com