Purifier for harmful gases

A technology for harmful gases and purification devices, applied in gas treatment, incinerators, chemical instruments and methods, etc., can solve problems such as hindering the uniform mixing of harmful gases, reducing the decomposition rate of harmful gases, and reducing combustion temperature, and achieve safe and stable purification treatment. , The effect of suppressing the accumulation of powder and preventing thermal diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0033] (manufacturing of purification equipment)

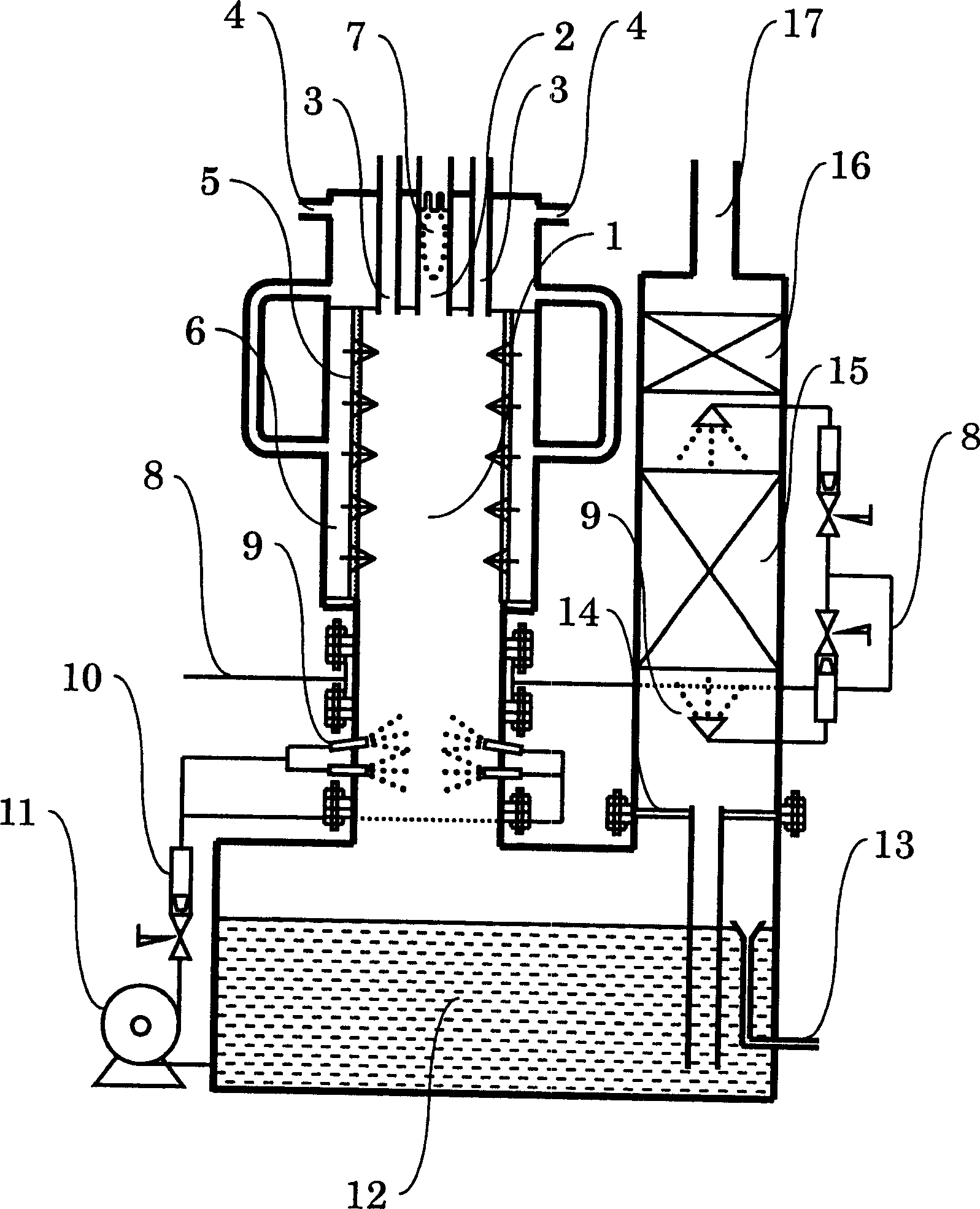

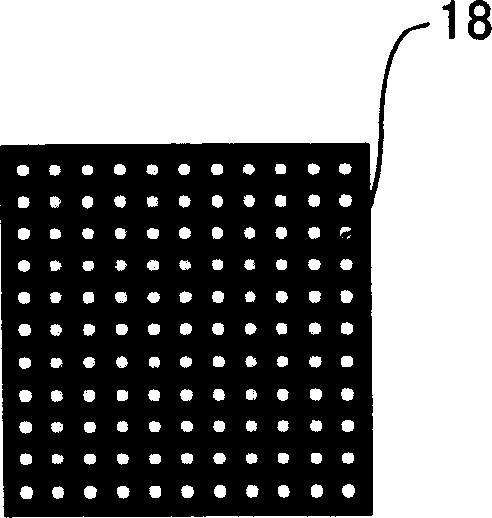

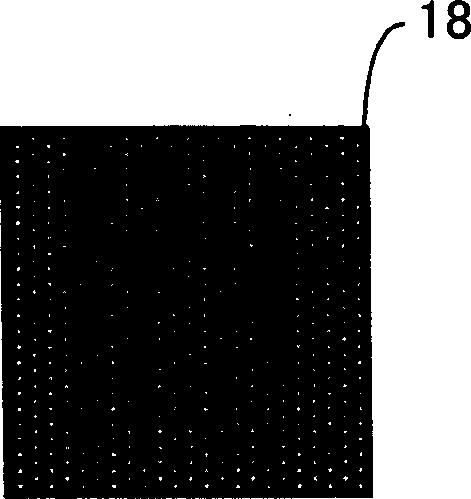

[0034] make figure 1 As shown, the outer wall is made of stainless steel (SUS316) and has a height of 2000mm. A cylinder made of aluminum having fine pores as shown in FIG. 2( b ) was used as the heat insulating wall on the side of the thermal decomposition chamber. The heat insulating wall has a diameter of 300 mm, a length of 600 mm, and a thickness of 25 mm, and has micropores corresponding to a diameter in the range of 10 to 100 μm. In addition, a stainless steel cylinder with a diameter of 480 mm and a thickness of 3 mm was used as the outer wall on the outer side. In addition, the inner diameter of the nozzle leading the combustion exhaust into the thermal decomposition chamber is 32 mm, the inner diameter of the nozzle leading the harmful gas into the thermal decomposition chamber is 44 mm, and the length is 200 mm.

[0035] At the bottom of the purification device, set a water tank with a longitudinal dimension of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com