Three-in-one combined core drilling outfits

A core drilling tool and combined technology, which is applied in the direction of extracting the undisturbed core device, earthwork drilling and mining, etc., can solve the problems of long auxiliary time, long drilling time, and many drilling times, so as to reduce the number of lifting and lowering the drilling , increase the pure drilling time, improve the effect of drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

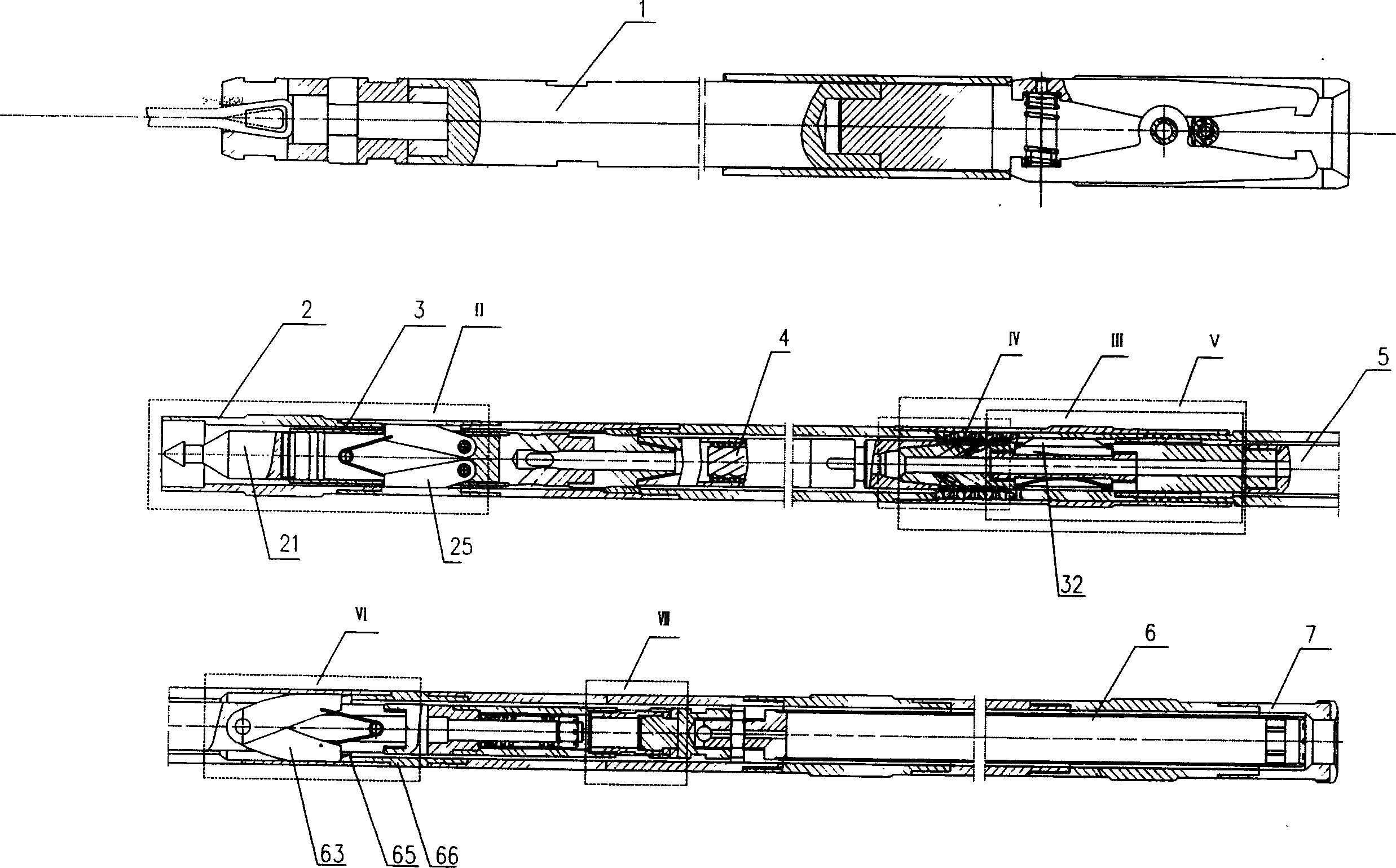

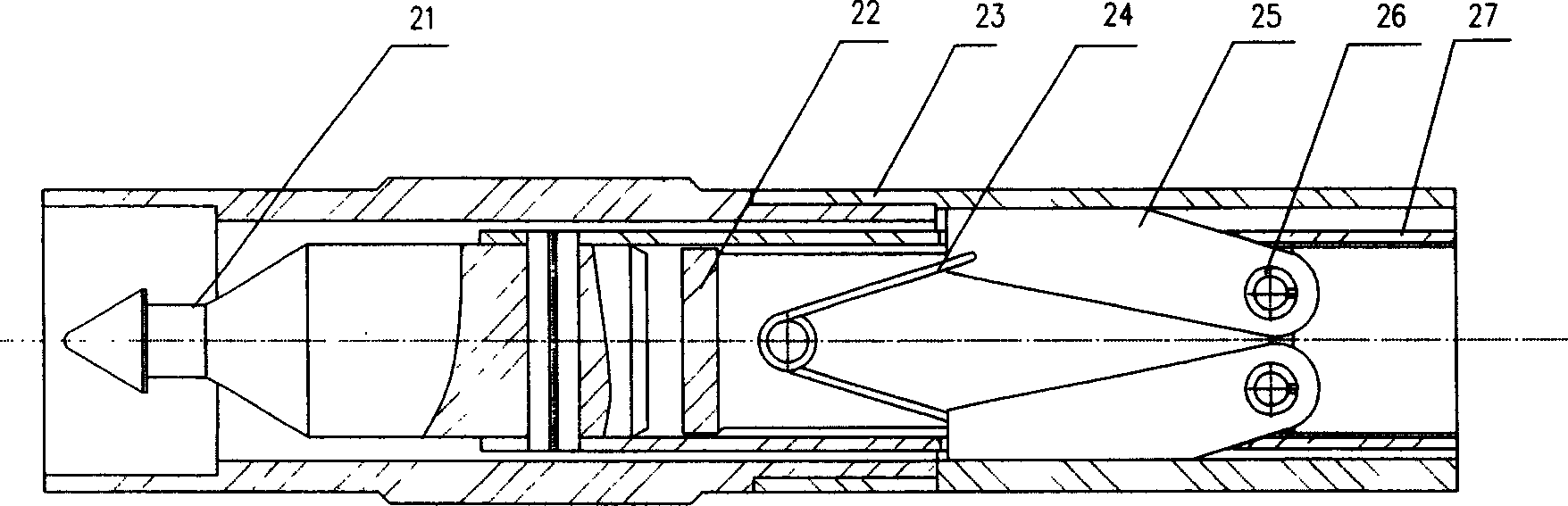

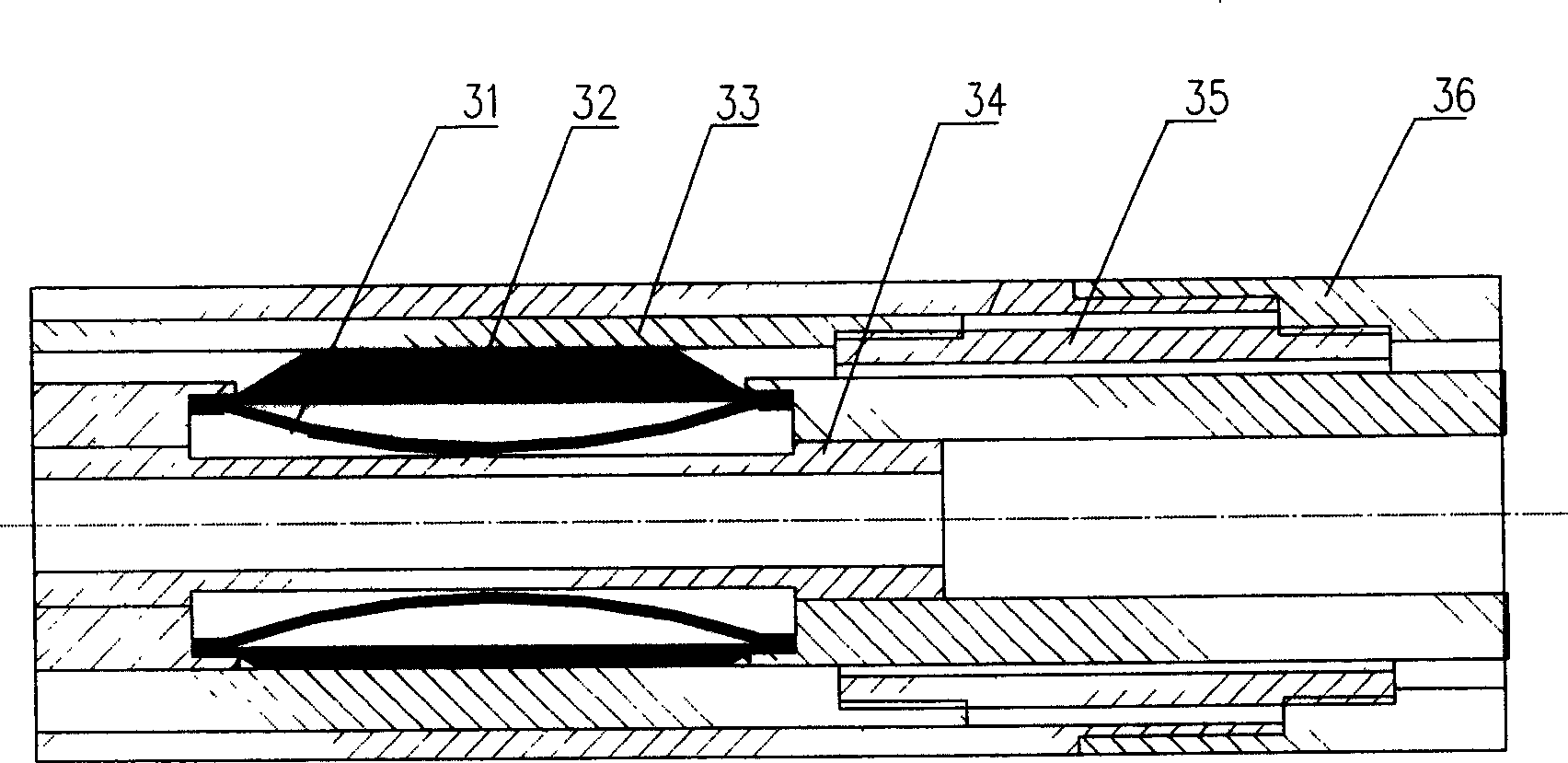

[0024] Such as figure 1 As shown, the present invention is used in deep wells, ultra-deep wells, and hard rock drilling. The three-in-one combined core drilling tool includes a rope fisher 1 placed on the surface, an outer pipe assembly 2, an inner pipe assembly 3, a screw rod Motor 4, hydraulic down-the-hole hammer 5, core holding pipe 6, drill bit 7 and corresponding positioning mechanism II, torque transmission mechanism III, flushing fluid diversion mechanism IV, outer tube single-action mechanism V, impact energy transmission mechanism VI, radial Fine-tuning mechanism VII. When the drilling tool is working at the bottom of the well, the upper drilling tool does not rotate, but uses the flushing fluid to drive the rotor of the screw motor 4 to rotate, and the output shaft of the screw motor transmits power to the lower drilling tool through the torque transmission plate 32 and drives the drill bit 7 to rotate . After the flushing fluid discharged from the screw motor 4 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com