Pressure power machine

A press machine and motive technology, applied in the direction of machines/engines, mechanisms for generating mechanical power, mechanical equipment, etc., can solve problems such as power and energy consumption, achieve fast running speed, ensure continuity, and operate safely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

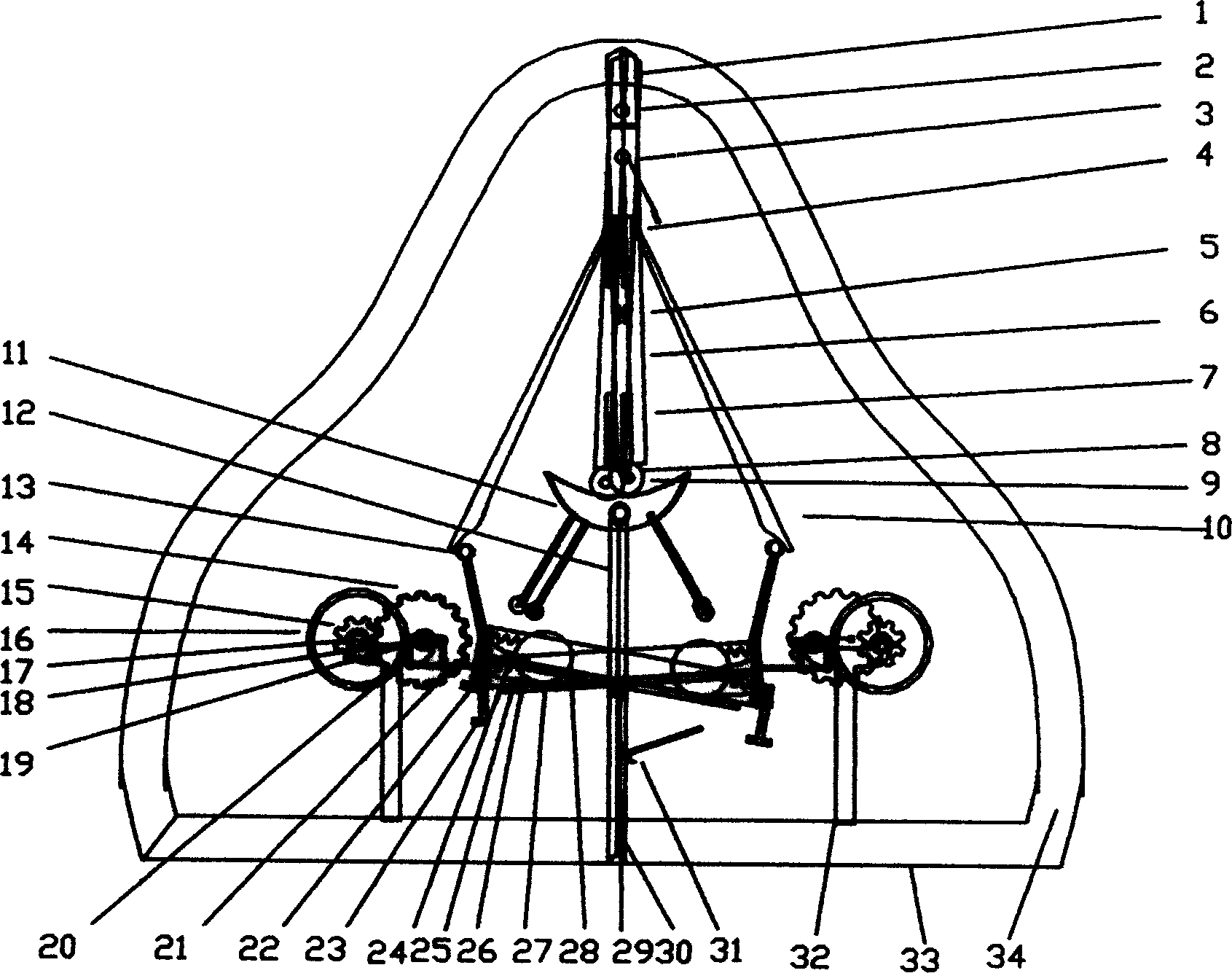

[0047] The following is a further description of the dual structure features and working principle of the compressor in combination with the accompanying drawings:

[0048] The present invention uses the principle of the earth's rotation to design a self-propelled press machine with air as the raw material. The press machine is composed of two parts and a hard steel device. The mutual connection of self-pushing and self-rotation is established on the double-structure device, and the double-structure is set. The device runs in reverse around the fixed point, and the joint force of the two parties can transform the fixed pressure of the high-pressure rod 1 into eternal power.

[0049] Two vertical cylindrical high-pressure rods (power source) are installed on the top of the press. The upper part of the high-pressure rod 1 is equipped with a rod top shaft 2, the lower part is equipped with a rod bottom roller 9, and the middle part is equipped with a pressure regulating rod 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com