Axial fan using electromagnetic bearing

A technology of electromagnetic bearing and axial flow fan, which is applied to bearings, shafts and bearings, components of pumping devices for elastic fluids, etc. The effect of short time, instant and agile adjustment, and increased reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

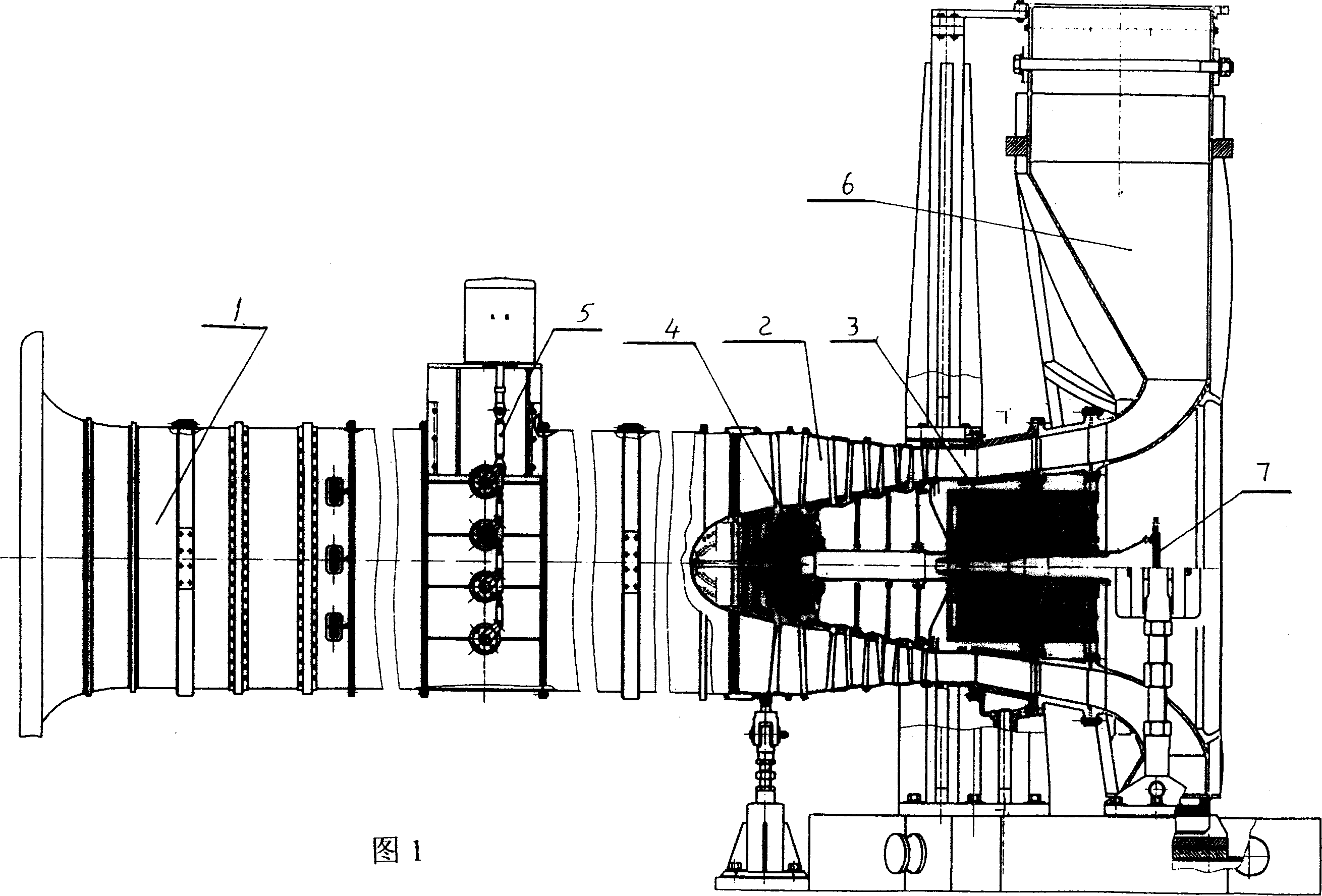

[0033] As shown in Figure 1, the axial flow fan of the electromagnetic bearing of the present invention is composed of five parts such as an air inlet 1, a throttling device 5, an axial flow compressor 2, an exhaust volute 6 and a support system, wherein the axial flow compressor 2 Composed of compressor rotor composed of five-stage rotating impeller, compressor casing composed of five-stage rectifying blades, front supporting electromagnetic bearing assembly, rear supporting electromagnetic bearing assembly and drive shaft assembly 7, etc., with the axial flow fan inlet as the The front end of the fan shaft and the installation position of the front support bearing assembly are shown in Figure 1.

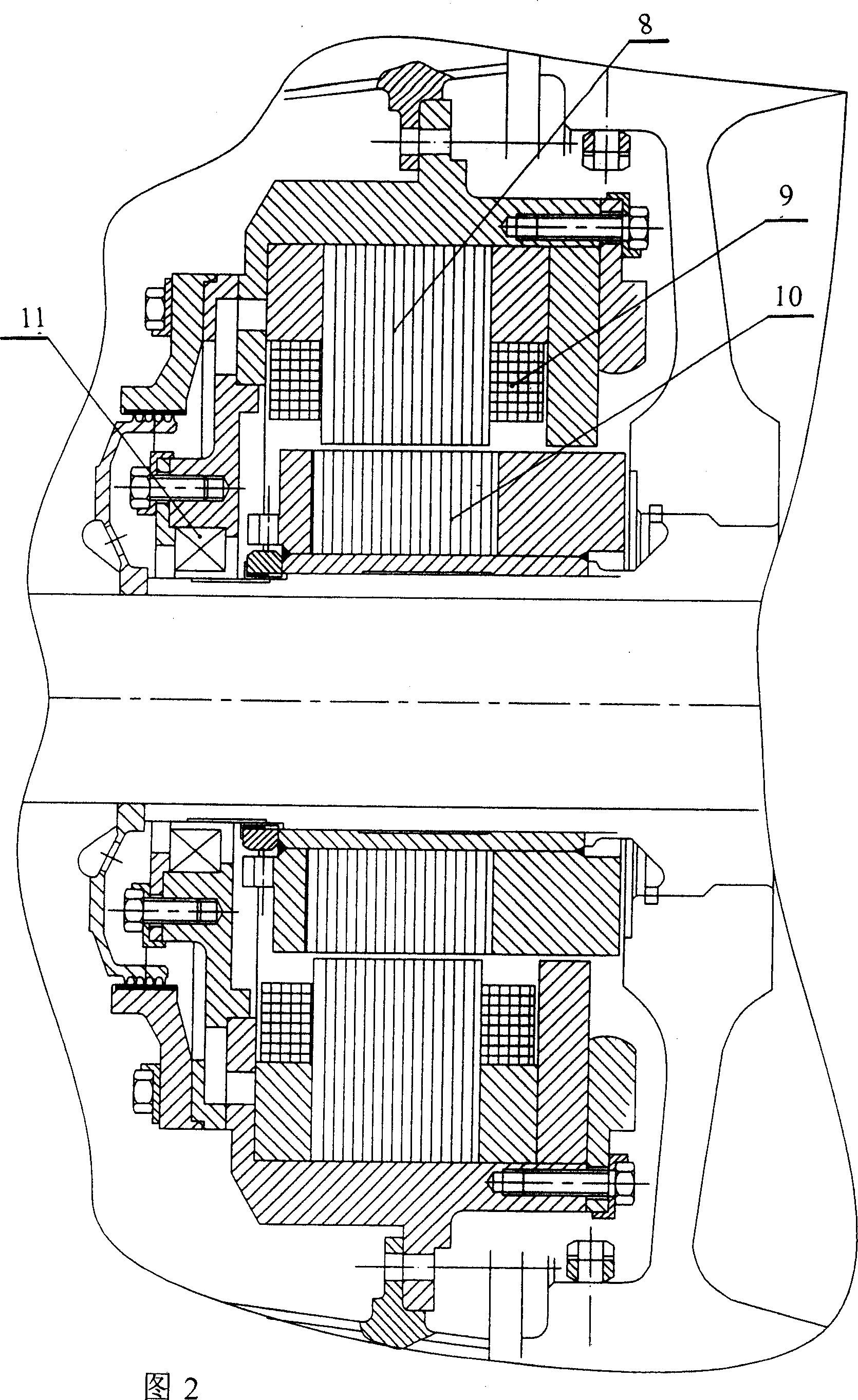

[0034]As shown in Figure 2, the structural diagram of the front support bearing assembly, the front support bearing assembly consists of a radial limit ball bearing 11, a radial positioning ferromagnetic core 8 of the radial electromagnetic bearing stator and a positioning electroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com