Oil ejector

A technology of oil injector and oil adjustment, which is applied in lubrication. It can solve problems such as unstable viscosity changes, damage to rock drills, and damage to rock drill parts, and achieve the effects of convenient and accurate adjustment, reduced wear, and improved use strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

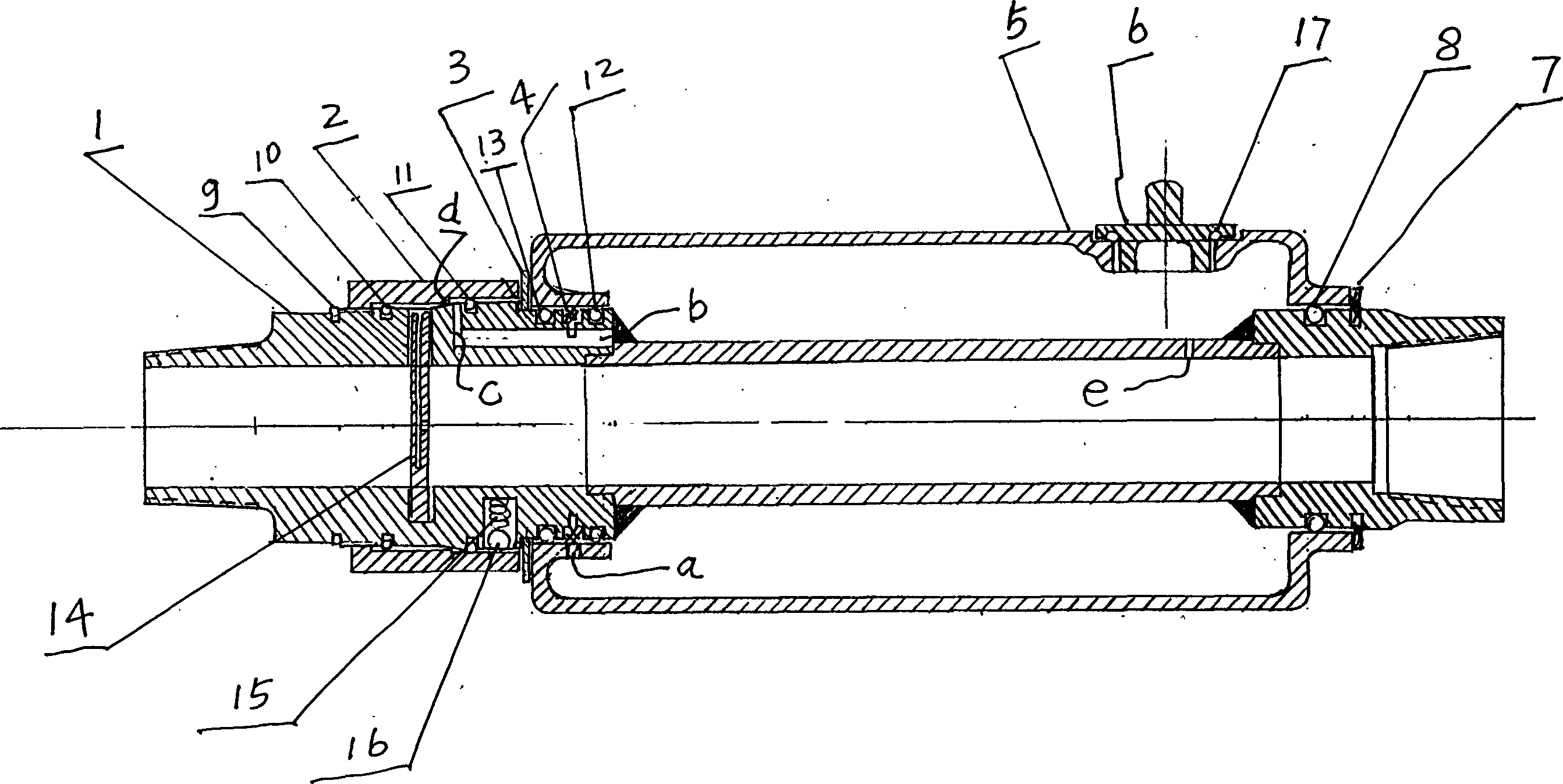

[0007] The use of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0008] Since the casing 5 and the welding assembly 1 of the oil adjusting mandrel and the parts such as the rubber ring and the snap ring form a completely sealed volume chamber, the lubricating oil is filled through the oil plug 6, and the compressed air is welded by the oil adjusting mandrel during the use of the rock drill. The central hole of component 1 passes through at high speed, and the small hole e on the oil-adjusting mandrel is blown into the sealing chamber. Due to the increase in pressure, the oil in the sealing chamber passes through hole a, filter screen 4 hole b. and Hole c. Through the adjustment gap ring between the oil volume adjustment sleeve 2 and the oil adjustment mandrel 1, it enters the oil outlet pipe 14 and enters the rock drill with compressed air to form lubrication. The amount of lubricating oil can be realized by turning the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com