Self lifting pressure liquid fuel gasifying burning stove

A liquid fuel, self-boosting technology, applied in liquid heating fuels, heating fuels, household appliances, etc., can solve problems such as overpressure phenomenon manufacturing costs, and achieve the effects of increasing costs, saving space, and preventing damage to stove components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

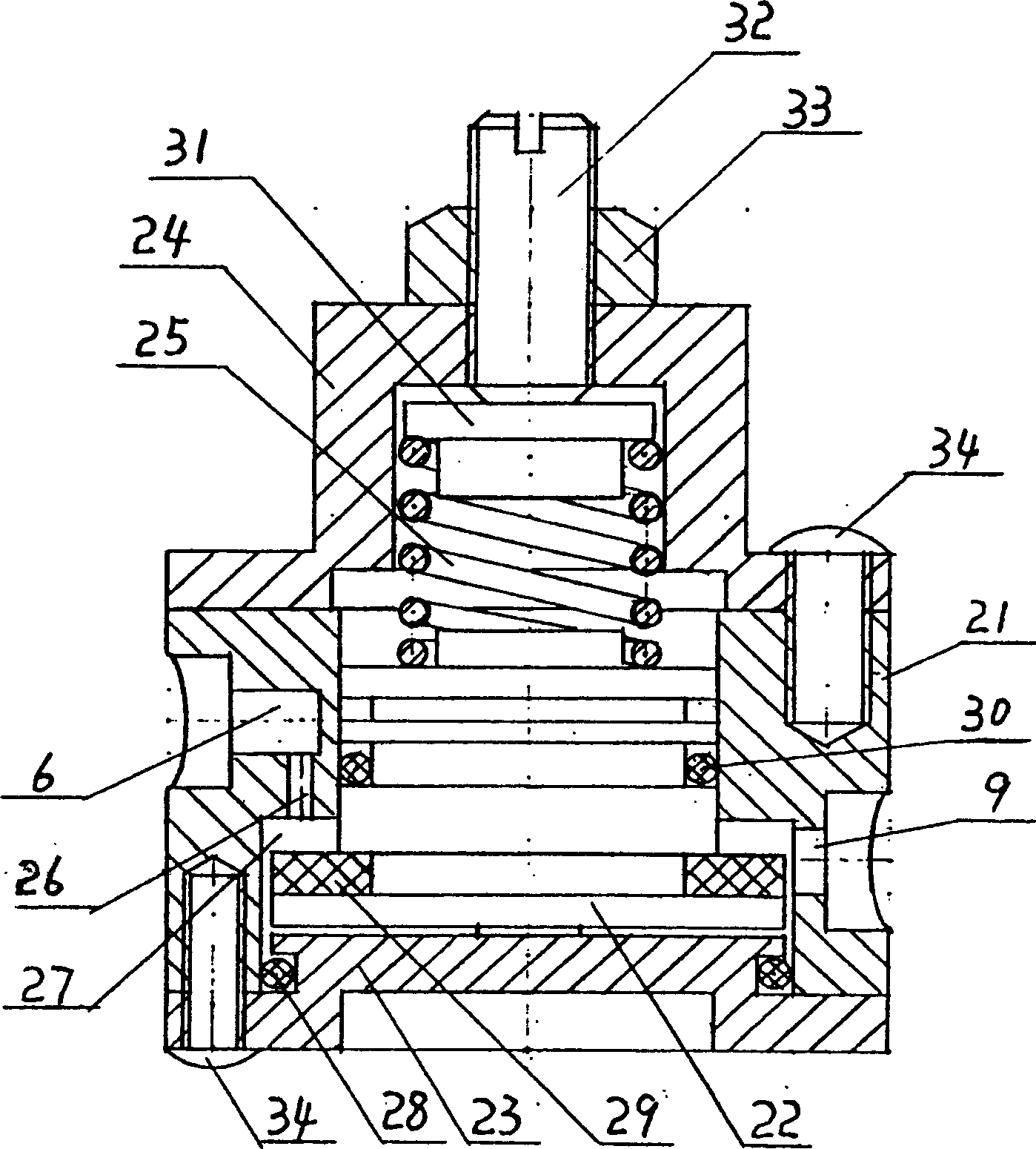

[0013] figure 1 It is an assembly diagram of the pressure limiting valve 3, including a valve body 21, a plunger 22, a lower end cover 23, an upper end cover 24, a spring 25, a spring pressure pad 31, an adjusting screw 32, a handle nut 33, a sealing ring I28, and a sealing ring II29 , sealing ring III30 and screw 34, the valve body 21 is in the shape of a round tube, the valve body 21 is provided with an inlet 6 and an outlet 9, the inlet 6 communicates with the inner cavity 27 of the valve through a vertical axial hole 26, and the outlet 9 communicates with the inner cavity of the valve 27 is directly connected, the plunger 22 is located in the middle of the valve body 21, a spring 25 is installed at the coaxial position between the plunger 22 and the upper end cover 24, the lower part of the inner garden of the spring 25 is set on the plunger 22, and the upper part of the inner garden of the spring 25 Covered with a spring pressure pad 31, the adjusting screw 32 is screwed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com