Accurately positioning method and device for underground layered power cable defect position

A technology for precise positioning of power cables, applied in the field of power cables, to achieve the effects of simple installation, avoidance of interference, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

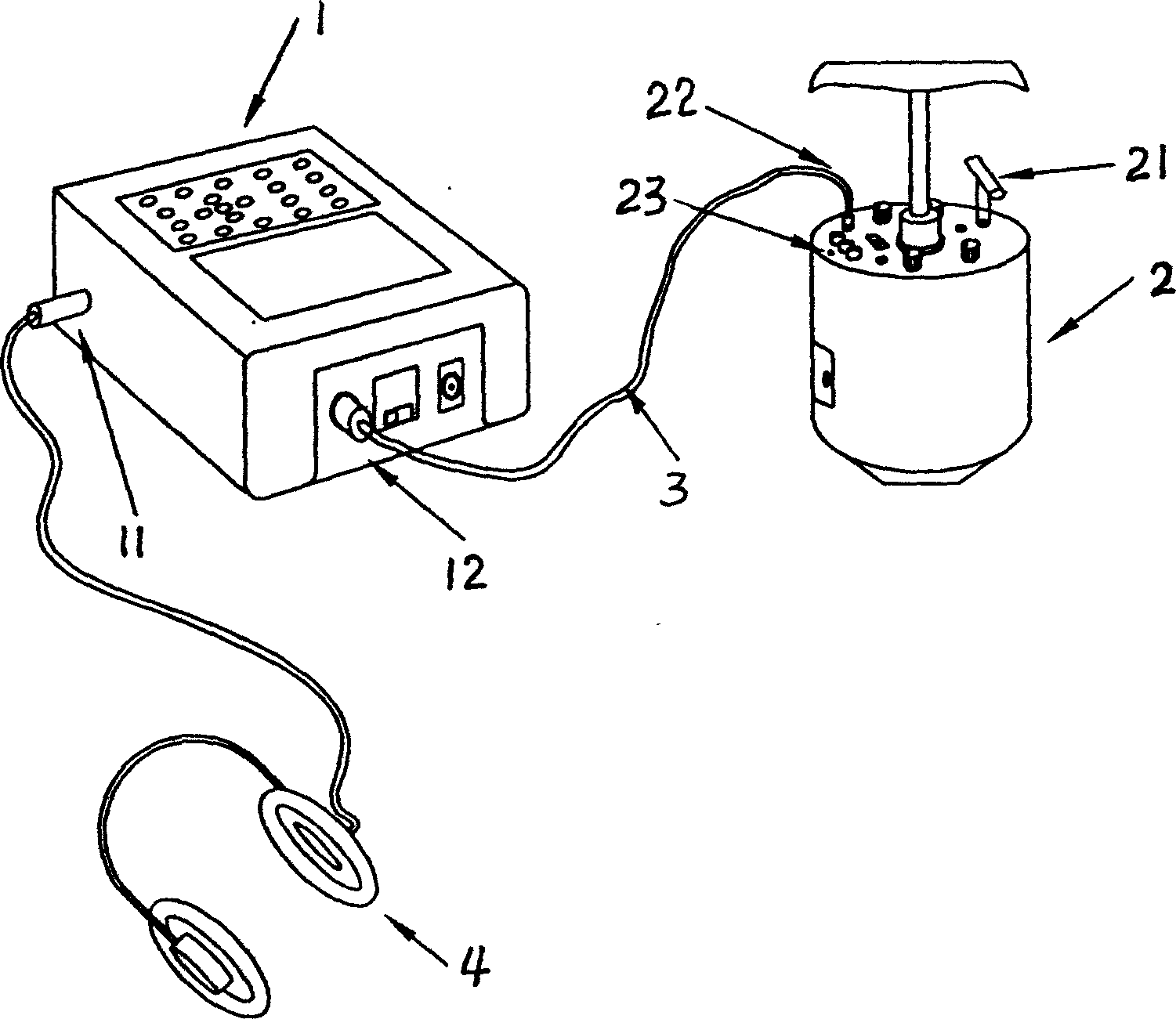

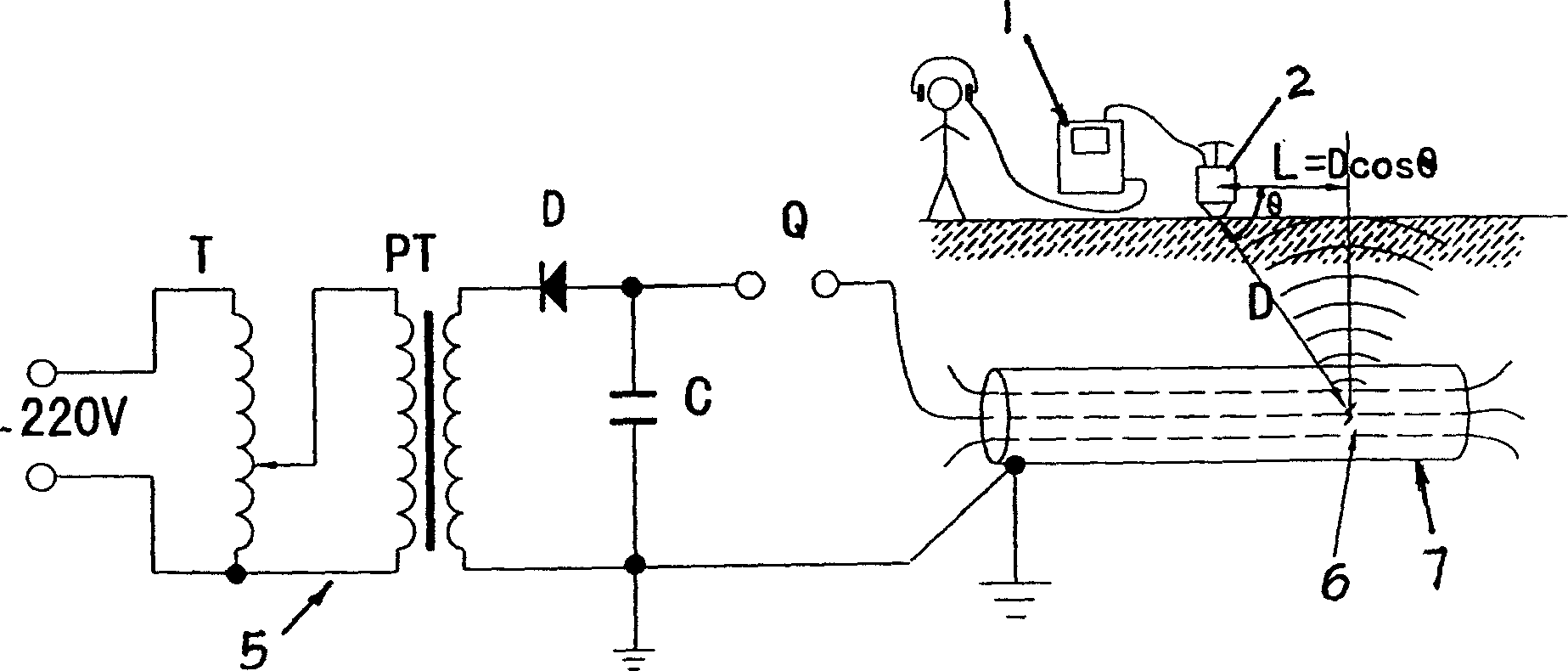

[0082] After completing the distance-to-fault range measurement, press the figure 2 Connect the high voltage pulse generator. Connect the output terminal of the high-voltage pulse generator to the faulty phase of the cable under test, and connect the outsourced high-voltage ground of the cable to the ground wire of the high-voltage pulse generator and then to the ground. By adjusting the pulse voltage level, control the pulse discharge frequency to apply to the faulty phase of the cable within 3-5 seconds. discharge pulse.

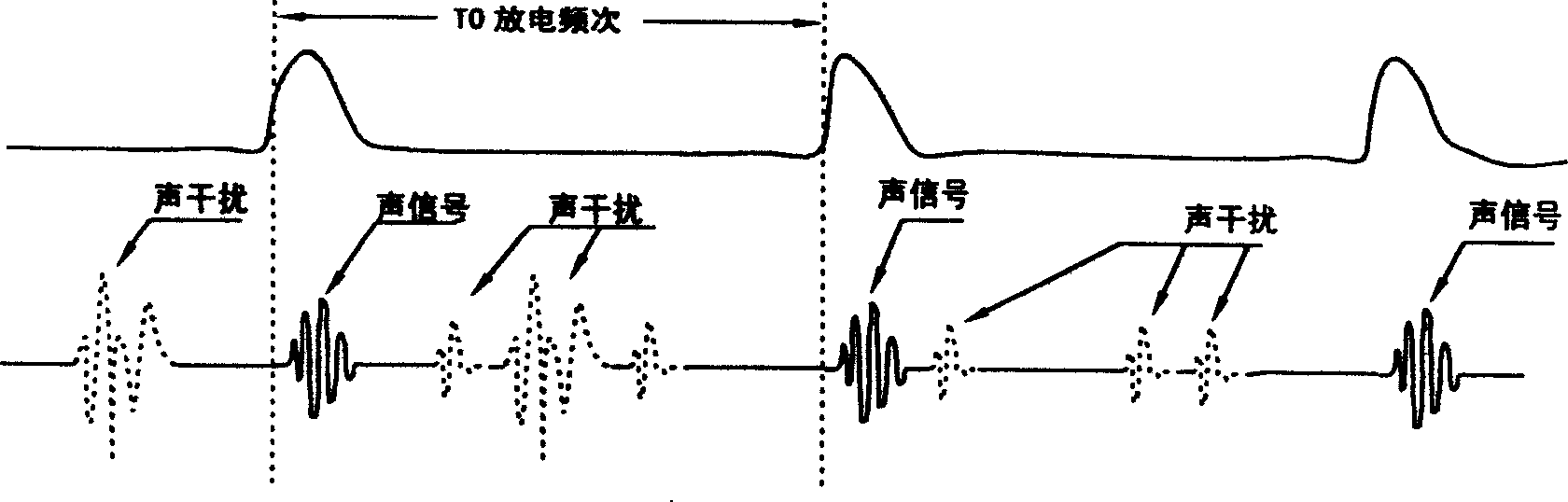

[0083] Within the cable fault distance range, according to the cable laying conditions, take two points A and B along the cable path, and measure the distance L between the two points. See Figure 7

[0084] Connect the magnetic-acoustic receiver to the data processing display through a special cable, and plug the earphones into the data processing display or the headphone output socket of the magnetic-acoustic receiver.

[0085] Turn on the power swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com